Engineering a borderless global company, ADM Group has identified its growth drivers in propulsion, emission, fluids and thermal management. In an exclusive interview with Founder and CEO Aman Mehtani, Rajesh Rajgor finds out how the group is powering growth, engineering future innovations and equipping people with purpose

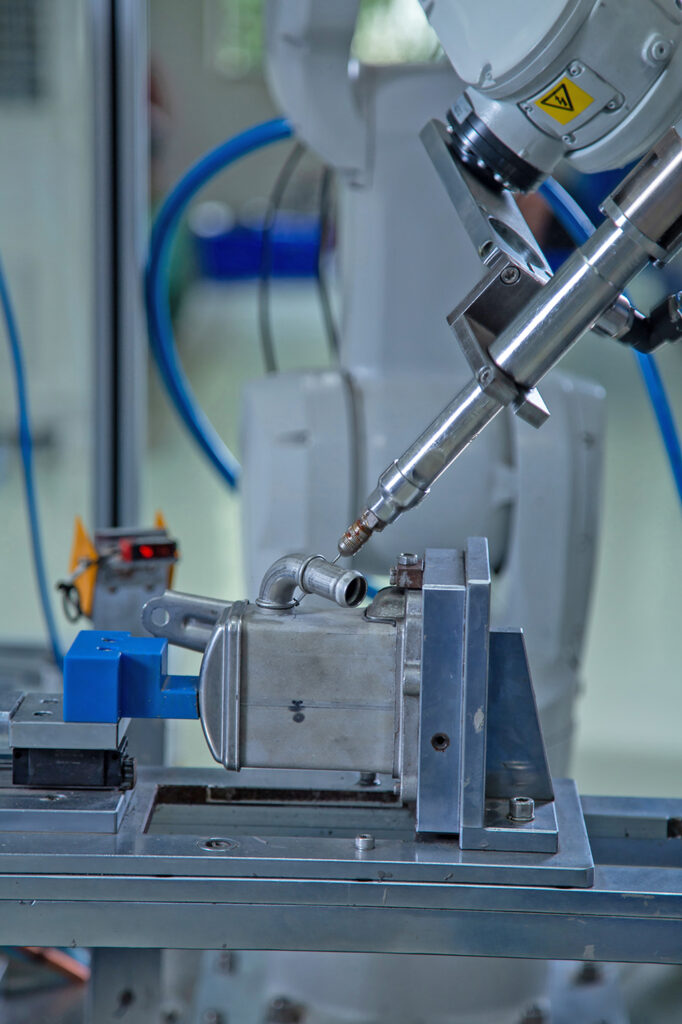

For more than a decade, the ADM Group has been at the forefront of developing smart, sustainable solutions. Their offerings currently cover products and solutions for emission, fluid transmission, suspensions and future mobility. Expanding on what started in 2007 with tube solutions for OEM and Tier II automobile players. “Our main area of concentration for the ADM Group is to deliver excellence throughout our engineering supply chain. We offer a variety of tubular solutions, including parts, sub-assemblies’ systems, bellows and flex connectors made using proprietary technology. Our tubular solutions are made to effectively meet the flow and thermal functionalities and performance of diverse fluids, including coolants, water, oil, exhaust gases, etc.”

Finding the Right Partners

All of the ADM developed products are included into the propulsion and power units, improving the performance, dependability through the life of vehicles. Only 30% of the hydro-formed tubes’ products are standard built to print, according to Aman, while 70% of their products are engineered. ADM’s products for bellows and heat exchangers are entirely custom-designed.

Elaborates Aman: “We are pleased to continue to be the leading OEMs’ go-to company for helping to develop and provide parts and sub-systems for propulsion and thermal management systems. We are paving the path for the OEMs’ present and future mobility needs through our three different JV companies in India with global technology players – Joinflex from Korea for EGR Tubes & Bellows, Sogefi from France for Suspensions and Yinlun from China for EGR & Oil Coolers. The Group is venturing into Future Mobility Tier 1 space, through new JV partners in India. These JVs will be bringing highly specialised products and solutions for the Future Mobility OEMs

Sogefi ADM is a JV in India of ADM Group offering solutions for suspensions systems, vehicle dynamics and importantly the overall driving experience of the vehicle. “Custom-designed, high on safety, light weight end fitment ready stabiliser and torsion bars made by ADM not only improve the vehicle dynamics but also driving experience in the worlds of passenger and heavy commercial vehicle and future mobility. Our customized CAE software captures our experience to come out with first time right stabilizer bars and capabilities makes precise calculations and durability through vehicle life. Hot & cold bending and tube bars production with bushes and bracket design under the same roof makes ADM competitive in market for capabilities and technology”, Aman informs.

Topping in Tubes Business

ADM Group today is proud of its rock-solid infrastructure, which includes cutting-edge technology, specialised material knowledge and a network of domestic suppliers. “We have strong access to and capabilities to develop smart, simple, tailored sub-systems ranging across low-volume, mid-volume and high-volume units thanks to our global experience and we are working on applications starting from three-wheelers, LCVs, passenger cars, off-highway vehicles, heavy-duty vehicles and agricultural tractors. In addition to having a unique understanding of grades and materials, we offer assembly expertise and setups for unusual combinations, hybrid parts and sub-assemblies,” he states.

In tubes, the group currently produces 5 million parts per annum. Post the BS VI transition the company has emerged as a preferred source to almost all of the OEMs in the diesel engine portfolio for hydro-formed tubes, even though there is a consolidation of the portfolio of diesel vehicles. Aman shares: “In 2019, there were 19 million diesel engines sold worldwide and we were the 21st largest provider. The world will produce 9.5-10 million diesel engines this year, which means that the production of diesel engines has decreased by 50%. Despite this, we rose to the top five suppliers in the world.

Dependent Sub-System Supplier

Aman Mehtani and the ADM Group are aware that possessing the required engineering expertise is a need, not an added benefit. “Due to our deep experience in engineering parts for cars, tractors, off-road vehicles and heavy-duty engines, we are not only versatile but also a reliable supplier, able to produce 250 different varieties of hydro-formed tubes. We possess industry leading production capacities, as also multiple technologies for forming, bending, brazing, laser welding, all installed inhouse”, states Aman.

Since 2012, the company has been manufacturing metallic bellows for exhaust systems of automotive and industrial engines and in the last financial year has invested into a world class greenfield facility for the same located at Pune. Notably, metallic bellows made by ADM also have large and wide applications in several non-automotive industry segments. Interestingly, the Bellows made by ADM are finding applications in new energy generation and mobility both. We are working to establish ourselves as one of the top three bellow manufacturers for the mobility industry. From present revenue of Rs. 15 crore at this greenfield facility we anticipate touching Rs. 200 crore in the next five years,” he says.

“With our expansion, our current annual production capacity for exhaust and industrial bellows will increase to 800,000 bellows,” he adds. Every part which goes into EGR Coolers made by ADM are designed and certified internally. According to Aman, by the end of March 2023, they will have the capacity to produce more than a million EGR coolers annually. “. He shares “Technology of our EGR Coolers better enhance the vehicular efficiencies on fuel and emission thereby significantly assisting reduce the pollution!”

Chalking the Roadmap

ADM’s future growth strategies are what they internally structure in Horizon 1, 2 and 3 (H1, H2 and H3). H1 would be using the current capacities and know-how for organic growth. H2 would be using current capacities and diversifying into powertrains for CNG, petrol, LNG, etc. H3 is all about future mobility, including hydrogen and other alternative energies, not just electrification. ADM Group has a three-year focused vision plan in addition to the budgetary year.

Aman elaborates: “For instance, in 2015, when we had revenues of Rs 42 crore, we said that we wanted to reach revenues of Rs 100 crore in 4 years. In 2019, we reached that milestone. Despite difficulties brought on by the pandemic, ADM Group will close this year with a top-line of around Rs. 500 crore with 40% revenue from exports, exceeding our goal of becoming an Rs. 300 crore Group in 2023. Similar to this, we have said that for FY 2026 that we would invest in future mobility while simultaneously growing ADM Group organically to close at Rs. 750 crore while working with a mix of young, talented and experienced engineers.”

Gearing up for Future Demand

ADM MobiTech is the new venture of ADM Group which is into the business space of Future Mobility constituting through several collaborations and JVs. With initial focus on vehicle electrification and hydrogen propulsion technologies, ADM Group is excited and confident of transforming growth through their new venture ADM MobiTech.

ADM Group is bullish about powering growth through diversification and adaptation of existing capacities for both ICE and non-ICE product portfolios. “Our FY26 targets for EGR hydro-forming tube business would be close to Rs. 300 crore. In bellows we would aim to achieve Rs. 100 crore and for suspension products we hope to clock a top-line of Rs. 150 crore. In EGR coolers we are aiming to be close to Rs. 150 crore,” Aman states.

What gives ADM Group the confidence of achieving the above feat is their prudent practices. One such practice is to keep investing and innovating to leverage R&D for customer needs and future offerings. “We will continue to increasingly invest into R&D capabilities. We have developed applications of our tubes, bellows and heat exchangers into engines using Hydrogen ICE as also Alternate fuels. We will continue to leverage our Library, our ability to seamlessly cater low to high volumes and keep the edge on better predicting life and performance of products through our engineering”, he explains.

Supplying Globally, Manufacturing Locally

An additional area for the group’s strategic growth is the North American market. The group, which has been a supplier to major OEMs is setting up a local presence in the region. “We are setting up a small manufacturing unit in North America as the market will continue to grow bigger, offering growth prospects in heavy-duty and off-road applications. It will help us be closer to the customer and also open up inorganic channels for further growth,” he shares. ADM Autotech, an aftermarket subsidiary of the ADM Group, manufactures and provides a variety of essential parts for various vehicles to large distributors in the developed markets of the world.

The company’s B2B business model is expanding, adding to the variety and range of products produced, as well as the manufacturing facilities established. “Our aftermarket division largely caters to exports. It addresses the need for reliable parts that OEMs and the owners of a sizable population of vehicles far too urgently require beyond the warranty periods. Additionally, the whole China Plus One sentiment has helped us. We are currently at Rs. 15 crore top-line but by FY26 we want to clock Rs. 100 crore in revenue”, Aman shares.

Logistics and ADM Foundation

ADM Group under its logistics and warehousing division has leased out a million square feet of space across the Delhi-Pune route and plans to add more space by FY26. “We began with an intention to have free cash every month and leased out a space we had to support our manufacturing business. Today it has grown phenomenally as an independent business and we have leased a million square feet already and would add another 500,000 square feet by FY26”, Aman informs.

In terms of logistics, what began with two trucks has grown to a fleet of 200 trucks. “We own close to 130 trucks and about 70 trucks are often attached from the market. The trucks form a strong network of supplying about 90% automotive components of customers in the Delhi-Pune corridor. As of today, only 10% of our assets is utilised for captive consumption. Within the automotive domain, the models of providing logistics solutions are evolving and so we are looking at digitisation and tighter integration of fleet management for our customers. We hope to reach a top-line of Rs 100 crore by FY 26 in the logistics and warehousing space from the current Rs 35 crore,” he says.

Surbhi Mehtani, is the Executive Director of the ADM Foundation (ADMF), supporting the CSR-implementing organisation of the ADM Group, which was established in 2018. The foundation works to empower people in order to enable sustainable communities out of a commitment to society. “We work to build a system that will enable people, notably disadvantaged youth between the ages of 11 and 21, to acquire the necessary skills to find employment. Our team has several programmes tailored to each member’s age and level of education, and we look forward to giving back to society in a comprehensive way. We cover topics like soft skills, shop floor training, environmental awareness and equitable chances for people of all genders and abilities,” Aman reveals.

ADM Group – Future Goals

- To be amongst the top three in the world in flexible tubing business, amongst the top three in India in stabiliser bars, amongst the top two in India in exhaust bellows and amongst the top three in India in EGR coolers.

- To become a great place to work.

- Best-in-class manufacturing and research and development facilities to support future product and technology pipeline.

- To be a socially responsible investor by launching an ESG framework and achieve sustainable skilling under the ADM Foundation.