Today, in the commercial vehicle market the term “automatic” is often used to describe any two-pedal set-up. But there are significant differences between a fully automatic and an automated manual transmission (AMT) that can affect performance, fuel efficiency and reliability in truck applications. As demand for fully automatic trucks and buses increases, the supplier finds a steady rise in demand for both on-road and off-road applications.

Today, in the commercial vehicle market the term “automatic” is often used to describe any two-pedal set-up. But there are significant differences between a fully automatic and an automated manual transmission (AMT) that can affect performance, fuel efficiency and reliability in truck applications. As demand for fully automatic trucks and buses increases, the supplier finds a steady rise in demand for both on-road and off-road applications.

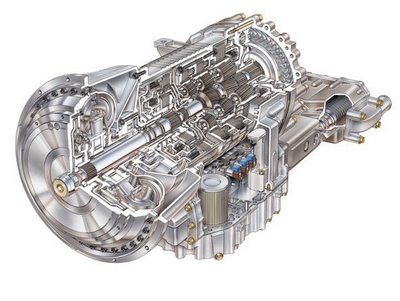

A manual or AMT transmission operates a traditional dry clutch to transmit engine power to the vehicle driveline and engages different sets of gears to achieve the various gear ratios. Conversely, in a fully automatic transmission, a continuous flow of power between the engine and vehicle wheels is guaranteed via a torque converter module, while a single, sophisticated set of gears produces all of the different gear ratios. This planetary gear set takes a central “sun gear” and outer ring gear with its teeth on the inside, and connects the two with a series of “planet” gears mounted on a carrier frame.

Torque converter

The torque converter device, evolved from the fluid flywheel, is located in the front of the automatic transmission housing and is filled with transmission fluid. This fluid transmits engine torque to the transmission during vehicle launch. Thanks to its architecture, the torque converter is key to the fully automatic transmission and provides many unique benefits such as multiplication of the engine torque and reduced shock and strain on the entire driveline.

Moreover, modern automatic transmissions incorporate a lock-up clutch in this module that, when required, provides a direct mechanical connection from the engine to the transmission to always maximize fuel economy.

It is the torque converter that provides many of the differentiators that establish performance between a fully automatic transmission and an AMT. With an AMT, every time a shift occurs the clutch separates the engine from the transmission. Therefore, at every shift, there is a loss of power, momentum and speed. With a fully automatic however, engine and transmission are always connected, leading to a more efficient use of engine power and fuel, thus providing faster acceleration and improved productivity. It is these attributes that led to fully automatics being the de facto choice in fire (performance and acceleration) and for city bus applications (efficiency, productivity and protecting the driveline during frequent stop/start operation). It is these advantages and others that are driving fully automatic transmissions into new applications such as distribution and construction.

It is these attributes that led to fully automatics being the de facto choice in fire (performance and acceleration) and for city bus applications (efficiency, productivity and protecting the driveline during frequent stop/start operation). It is these advantages and others that are driving fully automatic transmissions into new applications such as distribution and construction.

Fuel economy

Historically fuel consumption for automatic transmissions has been a concern, but much of this relates to early forms of the technology and not the more recent offerings. The commercial vehicle market is focused on executing “work” at minimum cost and fuel consumption. The new generation of Allison electronically-controlled fully automatic transmissions optimizes the efficiency of the truck or bus operation assuring that at every shift there is no loss of engine power. This makes it possible to get excellent fuel efficiency with an automatic transmission.

One example in a very harsh environment is the terminal tractor used in ports around the world. In an industry where productivity is king, operators are also looking at fuel costs. “Allison’s application engineers recently enabled us to reduce a customer’s fuel consumption by up to 25 per cent by calibrating the company’s terminal tractors to the specific conditions”, says Thomas Wong, Sales and Marketing Manager at Kalmar Asia Pacific Ltd. in Hong Kong.

Experiences in France also suggest that an automatic transmission is well suited to CNG truck applications. French store Monoprix has just ordered 26 Renault and Iveco trucks with fully automatic transmissions to target “best practices in distribution” with a specific aim to deliver better fuel economy.

Reliable performance

Losing control or traction on muddy, sticky or slippery ground is an issue for truck drivers in construction. Construction sites are not known for their easy working conditions, and in bad weather the problem can become at best irritating and at worst dangerous. “When you deliver concrete, ground conditions can be really bad,” says Lars Persson from Swedish industrial transport company, Tanum. Persson drives a Scania R420 fitted with an Allison automatic transmission and finds it helps him to maintain vehicle control in even the toughest ground conditions. “Thanks to the converter in the gearbox, whatever the ground might be like, the truck pulls away really gently and easily without getting stuck or splattering mud. And it’s great to have the engine’s power continually delivered to the wheels – with no interruptions for gear shifting”, he adds.

“Thanks to the converter in the gearbox, whatever the ground might be like, the truck pulls away really gently and easily without getting stuck or splattering mud. And it’s great to have the engine’s power continually delivered to the wheels – with no interruptions for gear shifting”, he adds.

An AMT can be at a disadvantage when operating in challenging conditions. Without the ratio multiplication of the torque converter, AMT is not designed to let the clutch slip for any extended time. Therefore inching out of mud or snow could be difficult. Even feathering the throttle isn’t as effective in an AMT; these conditions can cause the clutch to slip, overheat and eventually stall the engine or force neutral to protect itself. Reliability in off-highway applications is critical and the benefits of a fully automatic are leading more OEMs to offer this. Recently, Astra, part of Iveco, announced the option of an Allison in its new HD8 tipper.

Allison is a trusted provider of gearboxes to over 250 OEMs across the globe. With a well-earned reputation for reliability, efficiency, ease of use and cost effectiveness, Allison automatics have become a popular choice for anyone who needs to reduce down time on site and keep their construction vehicles moving.

“We have learned from our customers that the Allison product is very reliable. When there is a requirement for an automatic transmission, we know that with Allison we can meet our customers’ expectations. We can fit it and forget about it!”, says Ing. Naccarella, Engineering Manager for the Astra HD8 platform.

For the European distribution sector, there has recently been an increase in the number of automatic equipped vehicles in operation. These offer a better driving experience than a manual or AMT by increasing driver comfort and safety as well as manoeuvrability at low speeds. A fully automatic offers improved control, particularly in tight loading bays or urban environments, but the real advantage in distribution is the productivity, and fuel efficiency.

An Allison automatic makes more efficient use of engine power, resulting in a 20 per cent reduction in time needed. Over the course of an average work day, more deliveries can be made and additional revenue can be earned by the fleet.

There are many other applications that s

uit an automatic transmission. The ability to include a retarder, thus saving wear on braking components, and the option of power take offs (PTOs) for pumps or other ancillary drives makes the fully automatic a versatile transmission. In fact, Allison has a range specifically for oilfield equipment, complete with upgraded materials for corrosion protection and fixed up shifts for oil pumping.

An automatic transmission is commonly used in airport situations too – everything from the twin engine-transmission fire truck through to the shunters that all benefit from the ease of manoeuvrability. Another example is the strong presence of fully automatics in the public transport sector. The very same reliability, efficiency, ease of operation and cost effectiveness are the key reasons for an increasing number of cities across the world to specify their city-buses with an Allison Automatic.

Last year Allison delivered over 14,000 transmissions into bus applications worldwide. Over 600 Allison transmissions were sold to Tata Motors, and are now being operated by Delhi Transport. Thousands of city buses across Asia include an Allison. These buses can be found in countries such as China, Japan, Taiwan, Mauritius, Philippines, Indonesia, Thailand, Malaysia, Australia, and others. Over 10,000 Allison-equipped city buses are now operating in Beijing, China. These buses will transport athletes and visitors during the Olympic Games.

With fully automatics also considered to offer lower running costs (no new clutches or flywheel regrinds for starters) and the possibility to protect the rest of the driveline from abuse, it is no wonder they are becoming increasingly considered by operators in a host of applications.

Allison Transmission, Inc. is the premier global provider of commercial duty automatic transmissions and hybrid propulsion systems. Its products are specified by over 250 of the world’s leading vehicle manufacturers and are used in many market sectors, including bus, refuse, fire, construction, distribution, military and specialty applications.

Founded in 1915, the Allison business, headquartered in Indianapolis, employs 3,600 people. Regional headquarters with dedicated support staff are located in China, the Netherlands, Brazil and Japan.

With a global presence in 80 countries, Allison has over 1,500 distributor and dealer locations. Allison generates annual revenues in excess of $2 billion.