Alkraft has been a pioneer in aluminium heat exchangers since the early 90s. The home-grown company headquartered in Chennai has come up with several innovations in aluminium engine cooling systems, with a number of firsts to its credit. As a leading manufacturer of brazed aluminium radiators, charge air coolers, oil coolers, and cooling system modules, Alkraft’s product verticals include automotive OEMs and aftermarket, industrial equipment, tractors & agricultural equipment, and power generation equipment.

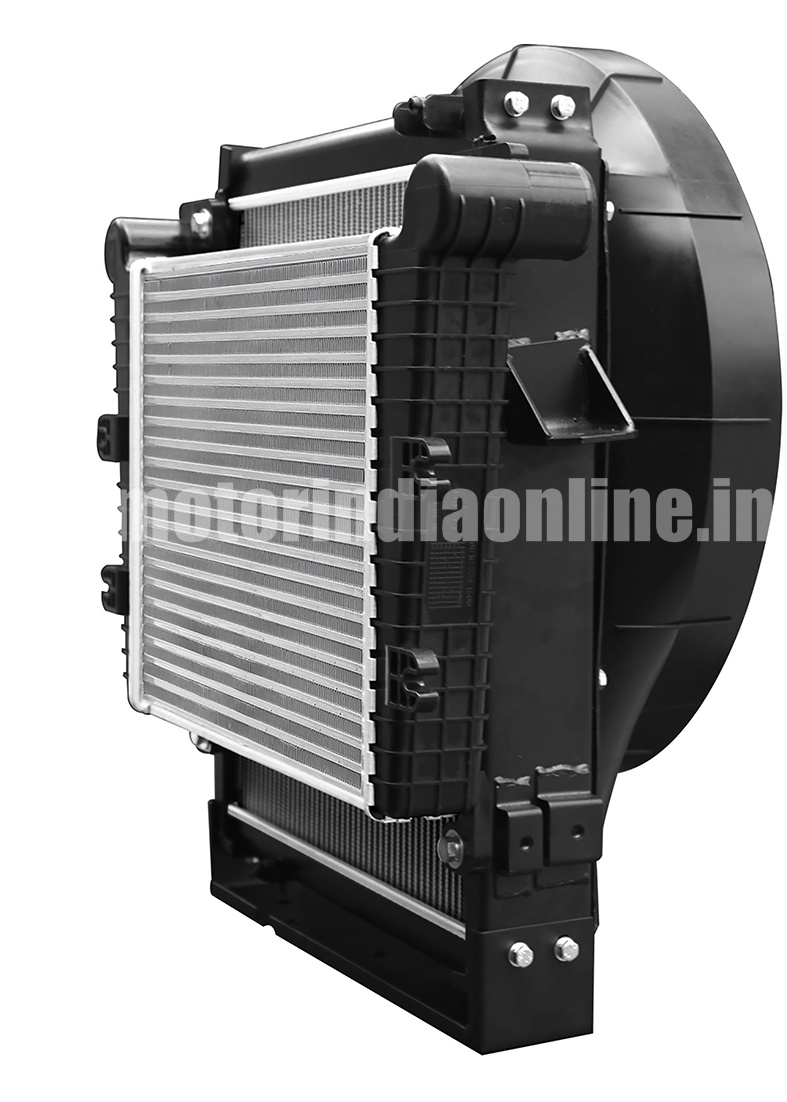

At this year’s Auto Expo, Alkraft unveiled a path-breaking innovation wherein it has questioned the basic construction of a radiator by placing the cores one below another rather than the traditional front and back design. Mr. Basil Mohamed Siddeeqi, Director, Alkraft Thermotechnologies Private Limited, explains: “We have a new radiator concept where instead of the usual front and back construction, we have done a top to bottom design. Our customers are excited with the product and we’ve already been cleared for an LCV platform by one of them. The innovative design results in a 17 per cent saving in weight and 27 per cent saving in volume which is quite significant considering the growing demands for light-weighting and down-sizing.”

Alkraft’s product range for the CV segment covers the entire spectrum from sub-1 tonne LCVs to MCVs, ICVs and HCVs above 49 tonnes. Its radiators, intercoolers, oil coolers and cooling system modules are the products of choice for leading manufacturers including Tata Motors, Ashok Leyland and Force Motors.

The company’s state-of-the-art manufacturing facility in Chennai has a capacity of over half a million HCV class heat exchangers per annum, translating to more than one million passenger car class heat exchangers per annum. The plant includes design, R&D and testing centres apart from complete manufacturing and assembly operations. Alkraft also has assembly facilities at Jamshedpur and Rudrapur (Uttarakhand) to support major customer plants in the Northern region.

Pioneering innovation

In 2015, Alkraft had developed a new core matrix of 44 mm thickness, the performance of which was better than a 48 mm thick competitor unit, while also being much lighter in weight as a result of the material used, construction and packaging.

Over the years, the company has challenged the stereotypical approach, and delivered ground-breaking products and innovations consistently. In 2003, it invested in folded tubes which were unheard of in the Indian market at the time and successfully used them in its products, much to the delight of its customers. The company moved to an upgraded version of the tubes in 2010, continuing to lead the field in technology adoption.

In 2004, Alkraft became the first to introduce long-life alloys in the Indian market, while its introduction of high temperature nylon for LCVs in 2007 was also a market-first. The company also received huge praise from one of its key customers for its indigenization of transmission oil coolers for one of its most successful HCV platforms.

“Alkraft has always set the pace in thermal innovations in India. We are the pioneers of this technology in the country since 1994 and were the first to introduce brazed aluminium heat exchangers, radiators, charge air-coolers, oil coolers in India. We’ve been bringing innovative technologies to meet customer requirements in terms of higher performance, lower weight and maintaining the right value. How to leverage technology and being a first-mover in the field to meet our customer needs has been the focus of our company”, adds Mr. Siddeeqi.

Coming up with new and advanced technology is no easy task, but ensuring the technology is a right fit for the market and offering the right value proposition for customers is perhaps equally, if not, more challenging.

“Being a home-grown company operating in the field for over two decades, we have strong knowledge of what works and what doesn’t in the local market. We do take inputs from global technology and gain knowledge from what happens across the world but we ensure our innovations are relevant for the Indian market, meet customer requirements and help solve their problems”, he remarks.

Ready for the future

Alkraft’s industry leading products have carved a niche for themselves and have consistently proven their superior performance, efficiency and durability. The company’s solutions for BS III and BS IV compliance and for improving fuel efficiency have been enabled by years of effort in research and innovation by its engineers and designers.

With BS VI being the talk of the town at present in India, Alkraft knows it would not be too easy to meet the highly-demanding requirements for thermal management, but is confident of gearing up for the challenge quite soon. “BS VI is a challenge which we as a market have to take up and work towards achieving for the benefit of the next generation. At Alkraft, we have been setting the trend and adding value in the Indian market and we are confident of meeting the challenges ahead. We are also happy that, in a way, our product plays a role in improving the environment and benefits the society”, he says.

Looking forward, Alkraft has an exciting list of tasks to accomplish. Apart from expanding its presence in other segments including the aftermarket space, the company is looking to make it big in exports in the coming year, as it plans for a massive upheaval in its financials in the next two to three years.

“Our major plans for FY17 include strengthening our presence in the tractor, power-gen, industrial and defence segments. Another key focus area for us is the aftermarket though it is a challenging space given the large amount of counterfeit products available in our country. We are also eyeing exporting our products to mid-sized OEMs in markets such as North America and Europe. In terms of financials, we closed FY16 with a turnover of Rs. 120 crores, which was a good growth from the Rs. 85 crores we did in FY15. The market is doing very well at present after a tough couple of years and if things go the right way, in terms of market demand and government regulations to scrap old vehicles, we should be able to achieve Rs. 300 crores in the next two to three years’ time”, concludes the Director.