By Ganesh Kalidas

With growing population in India, cities face a huge challenge of handling large amounts of garbage on a daily basis. To keep cities clean and green, every municipal corporation and its contractors are looking for quality garbage handling equipment. It is in this demanding situation that Antony Motors of Mumbai introduces its high technology, value-for-money garbage compactors in collaboration with Heil of the US.

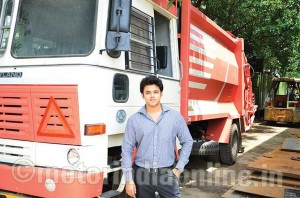

“We started with fabrication of bus bodies on chassis for various States and Corporation-owned city buses and subsequently diversified into fabricating special-purpose vehicles like bulker, trailers, containers, fire fighting equipment, suction and jetting machine, ambulances and so on”, says Mr. Edison Thomas of Antony Motors, the next generation entrepreneur who has stepped into the business, in an exclusive interview to MOTORINDIA.

Antony Motors Pvt. Ltd. progressed under the leadership and guidance of Mr. K.O. Antony, its Managing Director, and Mr. K.O. Thomas, Director – Production.

Young directors of Antony, with their vision and understanding of the global and domestic markets, have added new feathers in the company cap by adding sophisticated aviation refuellers and refuse compactors with a tie-up with international giants like Titan Aviation of France and Heil. “For 2013-14, we made over 400 compactors. We are the suppliers for BMC. We have supplied more than 500 compactors for BMC, 100 units for the Chennai Corporation and two our sister companies Antony Waste, AG Enviro, etc. We have set up our own galvanizing plant in the factory.

Talking about the company’s expansion plans, Mr. Thomas says: “With the younger generation into the business we are into waste management also. Our sister company, Antony Waste, has collaborated with Lara of Brazil for Garbage Landfill projects. We have bagged a contract in Kanjur Marg for waste processing and engineered landfill, which will be a different dumping ground altogether. We have already started the project which will be the biggest waste processing and engineered sanitary landfill project in the country to process nearly 4,000 tons of garbage a day. The area for the project spans over a 100 acres of land. Regarding refuellers and tanks, we have acquired a land in Patalganga and are planning to shift our existing operations in Mahape, in Mumbai, to the new facility which will have advanced machineries like dish bending, plasma, CNC m/c, and so on.”

Titan Antony has been supplying refuellers to big oil companies like Indian Oil, Bharat Petroleum, HAL, HP Aviation, Reliance Aviation, Jindal Group and Essar. The company also exports filters used in refuellers to countries all over the world.

Antony’s compactors come with high quality imported parts. It has a 95 per cent market share in Mumbai in government as well as private organisations. The company has a capacity to make more than 30 compactors a month.

He further says: “We have also made 50 units per month which is the fastest delivery anyone can give in India. The kits we give are of best-in-class quality. The trucks we use for our compactors are the ones from Tata Motors and Ashok Leyland wherein we have Ashok Leyland dealership in the Mumbai region since two years.”

He further says: “We have also made 50 units per month which is the fastest delivery anyone can give in India. The kits we give are of best-in-class quality. The trucks we use for our compactors are the ones from Tata Motors and Ashok Leyland wherein we have Ashok Leyland dealership in the Mumbai region since two years.”

As a major supplier of garbage compactors and refuellers to most government and private bodies in India, Antony Motors has achieved a total turnover of Rs. 45 crores in 2013-14, of which 90 per cent is contributed by the compactor business. With enough business in hand already, the company targets a 20 per cent growth in the current fiscal.

Talking about his future ambition, Mr. Thomas says with good Indian roads, he wishes to make side-lifting compactors.