In this exclusive interview with Prabhakar Chaurasia, Founder and CEO, AutoApps Engineering Solutions (P) Ltd., Rajesh Rajgor obtains details about the precision application engineering offered by the company in the Indian automotive space, particularly in the truck trailer segment.

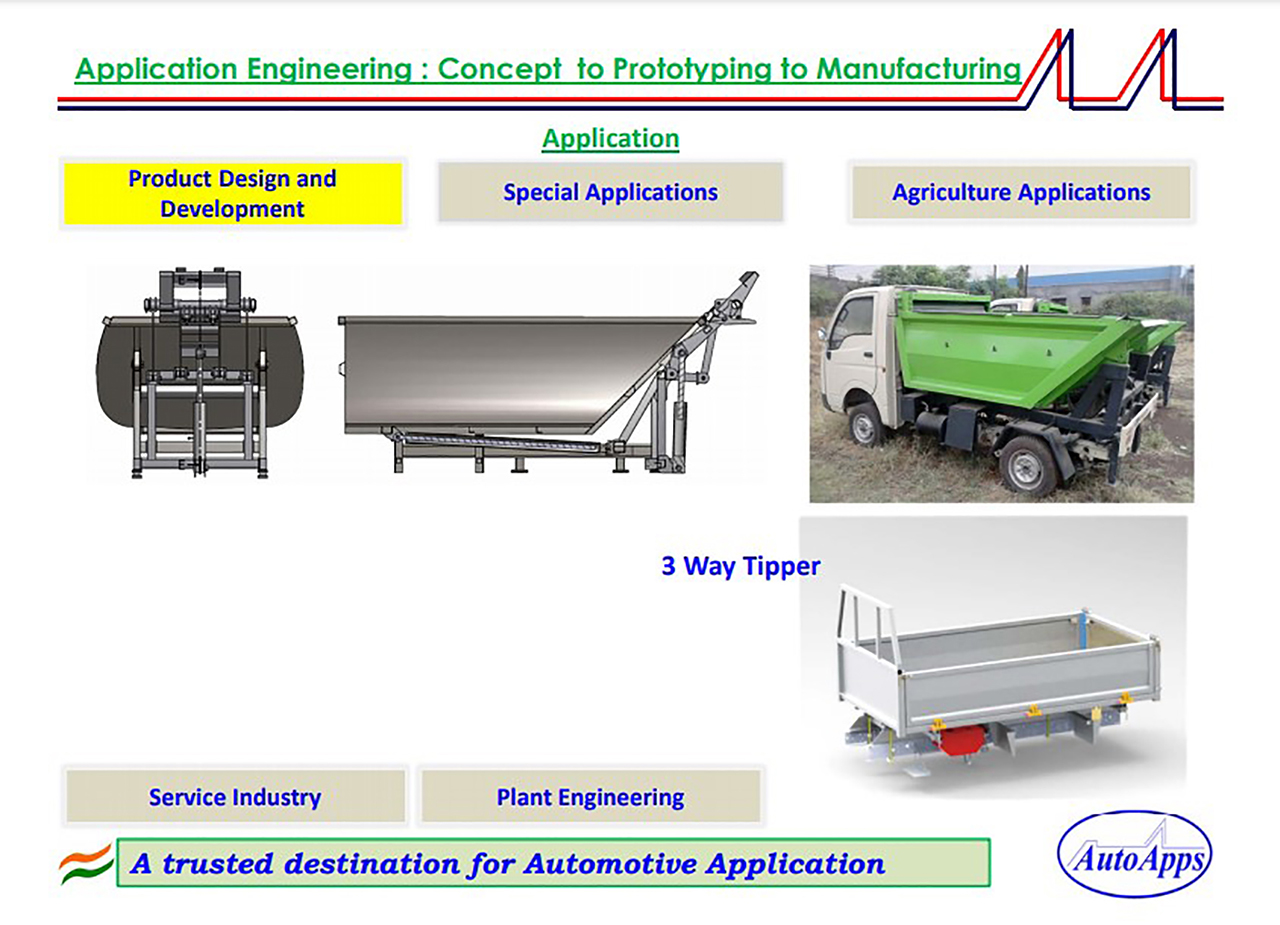

AutoApps Engineering Solutions (P) Ltd. (AutoApps) is a known name in the engineering of automotive application domain, particularly in the truck trailer and tip trailer segment. The man behind the company founded in 2014 is Prabhakar Chaurasia, an engineering graduate from GEC Jabalpur, 1993 batch, with over two decades of experience in the automotive applications’ engineering space. He has worked with renowned companies like Hyva, Palfinger Cranes, KVUL, etc. Today, AutoApps offers end-to-end solutions for plant and manufacturing engineering, jigs and fixtures, product design and CAD services.

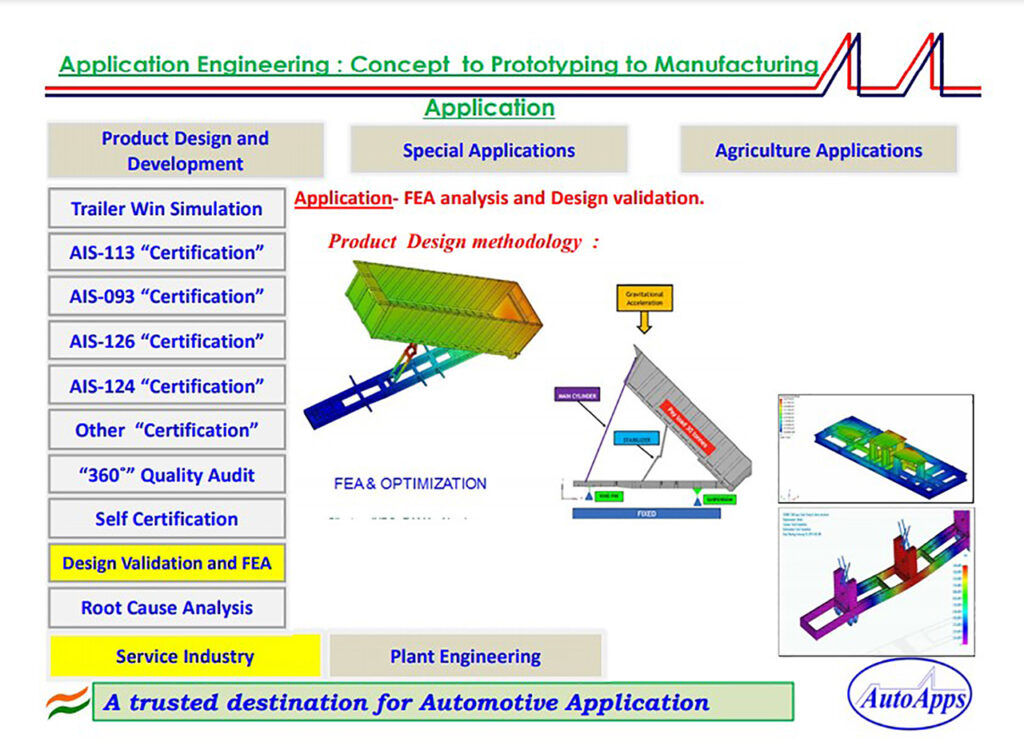

It is also engaged in the domain of customised material handling solutions, truck-mounted applications, as well as plant audits for OEM certifications, trailer consultation and vehicle stability by Trailer Win software and homologation and certification of products under various AIS norms such as AIS 093, AIS 113, AIS 125, AIS 124, etc. Sharing details with us, Chaurasia says: “Over my two decades of in-depth engineering experience with esteemed organisations like Hyva, Palfinger Cranes and KVUL, I had great exposure to application engineering and product development. Creating structural documentation of the product development process and performance feedback generates an invaluable asset for a company which enables transfer of knowledge to the future generation and prevents companies from facing the same problems over time.”

“One of the biggest challenges which I can see is to keep record of trials and store the experience of our predecessors in terms of design records, technical data storage and mapping of product development stages. The small effort of today for data recording, documentation and system creation can create a big impact for the future,” he adds. Today, AutoApps deals with different business verticals on a project basis with a team of qualified engineers to perform different tasks.

“We have worked with players in the automotive manufacturing industry to those in beverages production and the bottling industry. From product development to product assembly and new concept development to product engineering – we know it all. We always work to take a challenge and get it done within the scheduled delivery time with customer satisfaction. Customers’ trust, reliability and transparency have been the key drivers for our growth in the segment. We have grown through word of mouth in the last five years,” Chaurasia states.

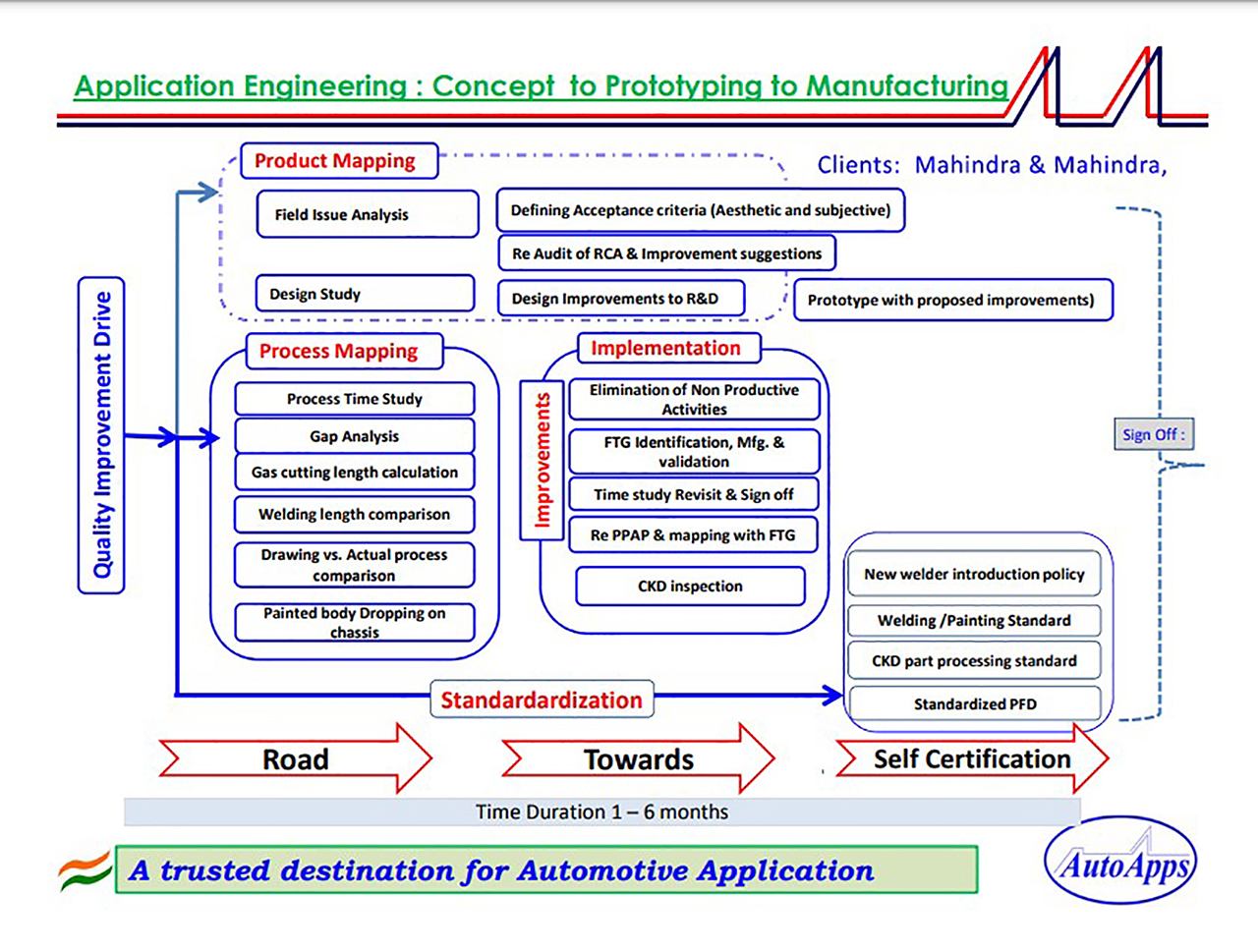

Plant Audit and Process Mapping

In the present scenario when we are living in very competitive environment where controlling product cost is one of biggest challenges, AutoApps’ work is to reduce product manufacturing cost as also decrease manufacturing process losses which is not noticed while manufacturing a product. For manufacturing plants, AutoApps provides 360-degree audit of manufacturing and processing plan for plant efficiency, process mapping and to identify the scope of improvement in the applications as well as at the plant level. The company inculcates counter measures to avoid losses and increase process efficiency by controlling various factors like material handling, manual intervention, input raw material, machine utilisation and process planning.

“We also check for root cause analysis of failure and defect and how we can strengthen our process to overcome them. We have executed 360-degree quality drive of tipper for Mahindra and Mahindra at Pune and for manpower optimisation at Radico Khaitan, a beverage company at Rampur, UP. In the short span of inception, we have initiated the fixing of complete lines to develop a tipper body and cargo load body in Chennai at KLT’s plant for Bharat Benz and AL. Similarly, we have established manufacturing facility development for Maurya Motors in Patna, MPS Auto, Indore and RV Industries, Hosur. Today, the plant enables them to undertake load bodies for OEMs like VECV, AL and Bharat Benz. Likewise, we have implemented a cargo body plant for MPS Auto at Pithampur, designed on single line multiple variants at 30 bodies a day for VECV products, which is unique in its segment,” Chaurasia informs.

Winning Trust with Consultation

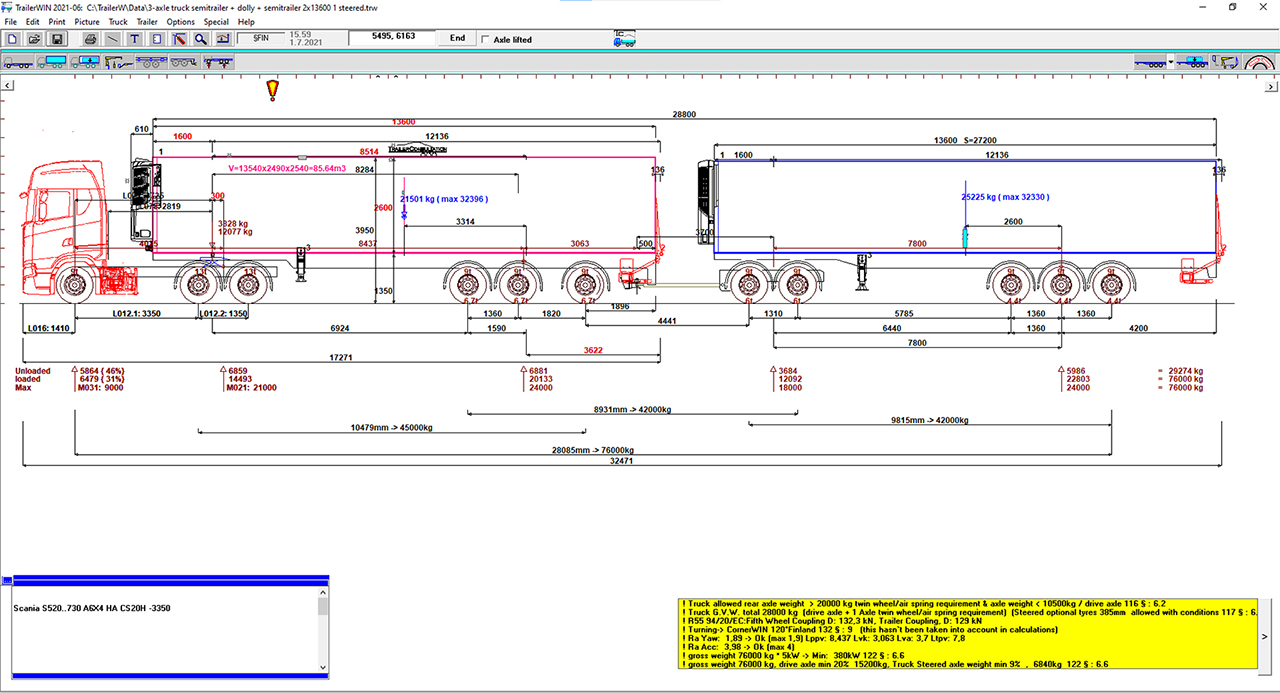

Vehicle dynamics and efficient design plays an important role for any manufacturer to attract customers as any field concerns have an impact on the image in the market, product and services. AutoApps is also an authorised marketing partner for the Trailer Win software used for brake and stability calculations, structure design validation and product behaviour after developing superstructures. Trailer Win has an inbuilt library of global product data base and is a globally trusted tool for engineering calculations for automotive applications.

This software is programmed for Trailer Win, Crane Win, Frame Win, Corner Win, Brake Win, Driveline Win and Bus Win. Chaurasia elaborates: “This software enables clients to do quick and efficient calculation for truck and trailer constructions with respect to weight distribution, axle loads, body building, mounting equipment (crane, rear lift, hook lift, truck, mounted forklift, demountable, etc.) and turning radius calculations. Our goal is to serve the industry with expertise in aspects like product management, concept designs, virtual prototyping, rapid prototyping, testing and validation.” Apart from the design and efficiency of business economics, enforcement of regulations such as AIS standards is helping the Indian trailer industry to move towards new technology in the segment.

This has resulted in a lot of development and awareness amongst the players. Chaurasia explains: “A lot of development is happening in the industry and almost 60% of the trailer manufacturers are getting certified by agencies either by iCAT or ARAI. The government’s initiation for improved norms for GCW 49T to 55T, inclusion of air suspension, and ABS and axle load norms are standardising the segment. MORTH has also been mulling over road train, given that the manufacturers are now on par regarding product quality with European manufacturers and also help customers on saving maintenance cost by preparing their maintenance schedule before failures.”

Riding the Change Wave

The company has also been engaged in training and development of teams for upgrades of the industry in terms of Industry 4.0 and shop floor training to perform tasks in a more synchronised manner.“Since visual inspection by using camera technology and artificial intelligence is the future for most of the industry players in terms of quality inspection, we are upgrading our own self to be able to implement it in the automotive manufacturing industry. We impart training and education, internship programmes and are currently helping 10 students of Amity University, Noida to do their summer internship programme on trailer certification under AIS 113. We believe this will nurture young talent for the imminent technological change,” informs Chaurasia. The country has already been witnessing skilled labour shortage and acceptance of truck-mounted application so that automation is going to be the way forward, especially the waste management segment, which is also moving to hook loaders. Eventually, adoption of technology in the onsite and off-road service segment in HT or LT line will further increase in the coming years. People will realise that make-shift manual solutions have limitations but a lot can be done with hydraulics and PTO on multiple truck platforms. In a nutshell, a lot of work is happening as regards research and development and technology-driven solutions have a lot of potential for India to make the markets more application-oriented. “Our offerings are thus aligned to support the industry and we believe India will have a conglomeration of European technology and the mass production capacity of China towards which our cost-effective offerings will aid the industry sail through change amid disruptions and various developments,” concludes Chaurasia.