The concept of ‘Energy-Efficiency’ (EE) is nothing new to the Indian automotive industry. Thanks to energy shortages, rising costs, increasing automation and freakish threats out of rising pollution levels and climate change, we can rightly assume that almost all vehicle manufacturers and big-name component makers have embraced eco-efficient strategies in their production processes. It has, perhaps, become a critical trend in recent years.

Yet, automotive manufacturing is so vast that its supply chain is one of the most complex, involving production and fabrication of raw materials (aluminium, steel, plastics, etc.), semi-finished materials (wiring, cable, hardware, etc.), and suppliers of components and subsystems extending up to three tiers – assemblers or system integrators (Tier-1), module suppliers of compressors, motors, etc. (Tier-2), and process-oriented suppliers (Tier-3) – apart from OEMs. The auto components industry, in particular, is dominated by Small and Medium Enterprises (SMEs) and is highly fragmented.

As per ACMA, a total of 575 organized players contribute to only 77 per cent of total output, while the rest of the production share remains with over 6,300 unorganized players, especially in the aftermarket and replacement segments. Therefore, any sustainability and resource management initiative in the automotive sector is bound to remain dormant without the active participation of these numerous micro, small and medium-scale suppliers.

As we realise, the SMEs involved in the automotive supply chain play an important role in growth and expansion of the Indian auto components industry, which contributes 25.6 per cent to the manufacturing GDP and 3.8 per cent to the national GDP, besides providing indirect employment to over 1.5 million people. However, as against OEMs and large suppliers, the SMEs face peculiar challenges like lower productivity, outmoded technologies, information gap, and certain structural barriers to low-cost finance and technology. Their energy efficiency levels are low and bear higher carbon-footprint, thereby lagging behind in both productivity and upgradation.

Energy is a scarce resource but a major input in this industry. Perhaps, the auto components manufacturing is one of the most energy-intensive, with applications like foundries and furnaces, cutting and milling, degreasing, drying, polishing, electroplating, ventilation, boilers and hot water systems, etc., consuming greatest amounts of energy. Therefore, any growth and expansion in this industry must accompany significant reduction in energy-use and resource management, from both the vantage points of productivity and environmental impacts. But, in reality, energy efficiency takes a back seat in the SMEs, as their priority remains to get the work done.

Although the adoption of low-cost automation (LCA) by some of the component makers has helped in this regard, there is still a long way to go to achieve the adequate energy efficiency levels in their processes. They fall prey to the vicious cycle of mediocrity.

“MSMEs are willing to invest on energy efficiency initiates on their own within their limits, even without external financing, if the return on investments are guaranteed”, says Mr. Bhavesh Swami of the Bureau of Energy Efficiency (BEE) under the Union Ministry of Power, citing that lack of performance guarantee for energy efficient equipments and poor synergy among various stakeholders are holding them back in this regard. BEE has set off a host of initiatives to popularise industrial energy efficiency among SMEs in India, with the experimentation of different schemes and projects, testing and measurement of impacts out of energy interventions.

In the auto components industry, it is also engaging with the OEMs, says Mr. Swami, to make them give sustained thrust on promoting energy efficiency among their suppliers, including Tier-2 and Tier-3. It is a win-win situation for both the OEMs and their suppliers in this regard, he adds.

Making the production processes and operations more energy efficient is likely to evolve as a new norm in the auto components sector. With the vision of ‘Industry 4.0’ and ‘Smart Manufacturing’ pitching in, the scope for industrial energy efficiency is wide open. Application of information and communication technologies (ICT) in energy management can offer real-time monitoring and data analytics. However, the structural challenges faced by SMEs in access to low-cost finances and technologies are mammoth.

There is a need for systematic support and patronage from all major stakeholders involved in the auto components industry. For instance, OEMs and Tier-1 suppliers can help SMEs in their supply chains to evolve energy efficiency investment proposals and ensure cleaner and efficient value chain. Financial agencies and energy professionals can embark on mechanisms to identify and finance those proposals from SMEs.

In this regard, knowledge sharing and awareness, along with training and skill development, becomes important. With enhanced performance and competitiveness, enabled by energy management, SMEs can engender sustainability in their businesses, both in terms of environmental impacts and business model.

Benefits of energy efficiency in SMEs

Today’s wastage is tomorrow’s shortage! Improving energy management in production processes can sustain your business and environment by:

* Reducing your overheads – energy and operational costs

* Improving maintenance cycles – extended lifespan of equipments, lower downtime risks

* Enhancing environmental performance of businesses, making manufacturing ‘dirt’ and ‘guilt’ free with reduced carbon footprint

* Making your business competitive – improved performance and customer satisfaction

* Providing safer and comfortable workplace

So don’t make your equipments ‘wait’, just ‘hibernate’ them. Kudos, energy saved!

BEE-GEF-WB Project: ‘Financing Energy Efficiency at MSMEs’

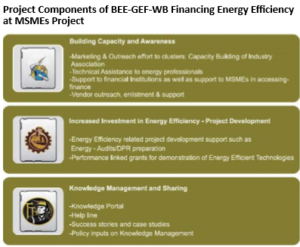

In a bid to bridge the gap between MSMEs, energy auditors and finance providers on energy efficiency projects, the Global Environmental Facility (GEF) under its Programmatic Framework (2010-14) for Energy Efficiency in India has taken up this initiative to increase the demand for energy efficiency investments in targeted MSME clusters and to build their capacity to access commercial finance. The implementation agency for this project is World Bank, while the scheme is executed by the Bureau of Energy Efficiency (BEE) and the Small Industries Development Bank of India (SIDBI).

As a part of BEE’s larger campaign of Energy Efficiency in MSMEs, this project engages in focussed efforts in five targeted clusters of forging, chemical and mixed industries – Ankleshwar, Faridabad, Kolhapur, Pune and Tirunelveli. It mobilizes a large group of ‘decision-ready’ units in partnership with local industrial associations, energy professionals, local service providers and leading vendors of energy efficiency equipments. Demand creation activities are then linked with lending programmes of various financial institutions in specific clusters.

Based on the findings of project-supported energy audits, enlisted units receive support in preparation of bankable Detailed Project Report (DPR) or application documentation to process loan applications under the current or new lending schemes and hand-holding support in reaching financial closure for identified investments.

The beneficiaries of the project are not just the participating MSMEs, but financial sector stakeholders, energy professionals and industrial associations are also seizing new business opportunities. “The project is a major step towards sustainability in the Indian MSME context, with capacity building and increased energy efficiency investments as its core objectives”, says Mr. Bhavesh Swami, Manager (Media), BEE-GEF-World Bank Program. The tiny manufacturing units are increasingly becoming cognizant of financial returns out of energy efficiency investments, and can help support other initiatives in this regard, he adds.

Six more clusters are identified for the next phase of the project – Delhi NCR, Varanasi, Ludhiana, Mumbai-Thane, Sri Ganganagar (Rajasthan) and Dehradun. The multilateral project, in its website www.indiasavesenergy.in, has created a ‘knowledge bank’ that lists out all suggested energy efficiency technology interventions and retrofits, along with a long list of vendors who supply those solutions and financing schemes, as a commitment towards knowledge building and awareness. Newsletters, YouTube videos, and media advertisements are also active to make a wider reach among the MSMEs.

For more details, visit: www.indiasavesenergy.in

Some energy efficiency measures and technology interventions (suggested under the BEE-GEF-WB Project)

* Energy-efficient motors, with standardised and skilled rewinding using suitable materials

* Installation of recuperator for heat treatment and forging furnaces

* Variable Frequency Drives (VFD) in air compressor, press and blowers

* Diode-based welding machines, in place of energy-intensive thyristor-based machines

* Installation of motorized blower for appropriate air to furnace burner

* Thyristor control for HT furnace for precise temperature control

* LPG-based furnace

* Energy Efficient Blower for furnaces

* Use of air guns in machine shop

* Utilization of suitable coils in Induction Furnace

* Induction-based heating

* Automatic Power Factor Controller (APFC)

* Energy efficient air compressors, with regulated air pressures

* Voltage optimization and servo stabilizer