Building on nine generations of fuel cell development, the compact design of Ballard Power Systems’ new FCmove®-XD fuel cell engine delivers class-leading volumetric power density, with an open architecture design approach that makes the fuel cell the smallest and lightest in its power range.

The compact FCmove®-XD module is scalable from 120-360kW offering an ideal solution for Class 6 to 8 trucks, delivering an easy integration platform for vehicle OEMs and integrators. The module is designed to deliver unmatched performance – with a driving range up to 800km complementing a volumetric power density that is the highest in the global truck industry.

The FCmove® range of heavy-duty fuel cell modules are designed, developed, and commercialized by Ballard, and are the longest serving fuel cells in operation. These innovative products have completed more than 200 million real-world kilometers and demonstrate market-leading performance with 25,000+ hours stack lifetime and 98% module reliability. It is this proven operational expertise and knowledge, built over 30 years of on-road experience, that informs and powers Ballard’s latest-generation engine.

“The requirements of the truck market are particularly demanding due to the high vehicle utilization rates and payload requirements. The FCmove®-XD is designed to deliver uncompromised power and performance for operators and efficient integration on new and existing electric vehicle platforms for manufacturers. Backed by Ballard’s open architecture design approach, the new FCmove®-XD module is developed for volume production and deployment to deliver competitive CAPEX and total cost of ownership values across heavy-duty truck segments.” said Nicolas PocardVice President, Marketing & Strategic Partnerships, Ballard

Innovation through fuel cell technology

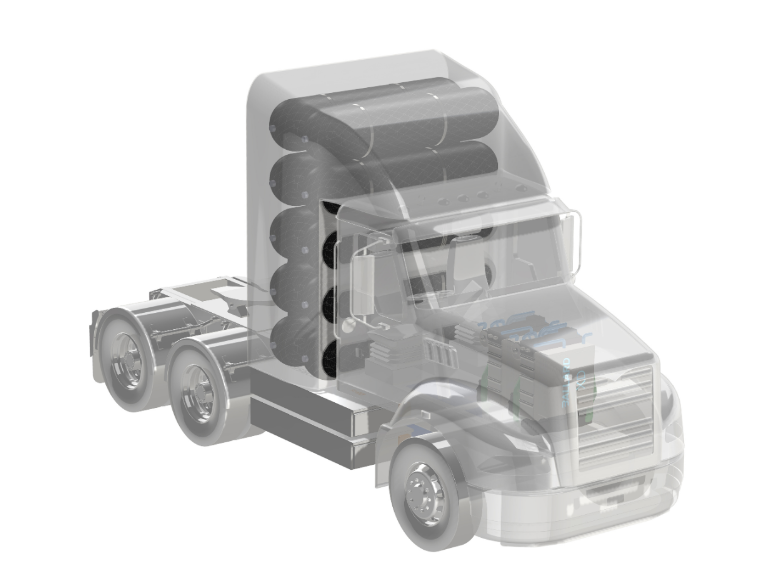

The core scalable 120kW fuel cell module integrates DC/DC regulated output, enabling up to three modules delivering 360kW, operating as one engine with a single interface. An integrated power controller incorporates the DC/DC converter, air compressor inverter, and a power distribution unit.

The open engine architecture delivers the highest published volumetric power density in the industry,and the high-efficiency engine enables low total cost of ownership, efficient heat rejection, and ensures a long driving range of 800km – subject to onboard hydrogen storage capacity.

Ballard’s latest FCgen®-HPS stack design enables a high operating temperature of up to 95°C and extended durability with low-cost carbon bi-polar plates.

The fuel cell’s open architecture design has resulted in a 33% reduction of parts and a 25% decrease in size compared to earlier modules. The FCmove®-XD is designed to fit in the space claim of a diesel engine and up to two units (240kW) can be installed longitudinally in the engine compartment of a heavy-duty truck, retaining easy access for service and maintenance.

Benefitting from longer range and faster refuelling than battery electric alternatives, fuel cell-powered trucks are also a true zero-emission solution compared to hydrogen internal combustion engines, producing no NOx or tail pipe emissions. As production scales up, the reduced complexity and efficient energy conversion delivered by fuel cells hold the most potential to offer the lowest cost solution to meet the requirements of heavy-duty mobility.

FCmove®-XD on the road

As one of the early manufacturers to adopt Ballard’s most powerful fuel cell engine, German e-mobility specialist Quantron has integrated two early production 120kW modules in its 44-ton QHM AERO fuel cell electric truck.

The QHM AERO offers class-leading range up to 700km, hydrogen storage capacity exceeding 50kg, and battery capacity of 120kWh. The truck’s hydrogen consumption is optimized by a specially developed management system, realizing maximum efficiency in the interaction between e-axle, fuel cell and high-voltage battery.

As part of Ford Trucks’ concerted shift to decarbonize its global fleets, Ballard will also supply the FCmove®-XD to Ford Otosan’s hydrogen-powered F-MAX FCEV heavy-duty prototype.

The fuel cell engine will be integrated into the 44-ton long-haul tractor, which will be built and assembled in Turkey for the European market; with Ten-T corridor demonstrations planned for 2025 as part of the European Union’s Horizon Europe Zero Emission Freight EcoSystem (ZEFES) project.

Demonstrating Ballard’s product platform diversity, the FCmove®-XD also powers Applied Hydrogen’s zero-emission 30-ton excavator. Based on the Volvo EC300E crawler, the vehicle is developed for Scandinavian construction company, Veidekke, and will eliminate approximately 60 tons of CO2 emissions per year.

Ballard will showcase its most powerful fuel cell technology at the international heavy-duty mobility IAA TRANSPORTATION 2024 tradeshow at Booth C01, Hall 24, in Hannover, Germany from September 16-22.

Headlining the company’s participation at the event, Ballard’s technical team will present a FCmove®-XD 240kW system, demonstrating the modularity, scalability and flexible integration that presents the heavy-duty fuel cell engine as the ideal fit for Class 8 trucks at 19 tons and above.