It is the equipment levels and driveability that defines a construction tipper and its dynamic abilities to stand out among other truck types. DICV’s modus operandi to crack the mass-market tipper segment in India is just the same, writes Dhiyanesh Ravichandran

Tippers are altogether a different breed of trucks, for the simple reason that they are always put to work in the most dynamic and challenging road and operating conditions. From open highways to broken ghat roads, or slushy mines to rocky terrains, tippers are designed not merely to haul and tip the loads, but are trusted for their dynamic abilities to wade through any type road and gradeability scenarios, and come out unscathed only to get ready to go through the ordeal over and over again.

Construction tippers, in particular, these days are largely run within a defined not-so-vast geo boundary, but are the real workhorses plying multiple trips round the clock. In other words, the routine itineraries of tippers are always looped. Gone are the day when tippers were simply meant only for niche tipping applications. They have become radically modern and equipped with essential and high-tech goodies to become the most-aspirational lot in the trucking stable today.

Case in point is the latest BharatBenz 2823C 6×4 construction tipper, a popular mid-premium contender in the most competitive class of tippers in India at present, which rightly embodies the rapid technological transformation and popularity that tippers are garnering. In my recent rendezvous with this truck for a test drive, I was more inclined to check its driveability, than aesthetics or cabin comforts. All I hoped was to experience and put to test its dynamic abilities that sets it apart from the rest of the lot.

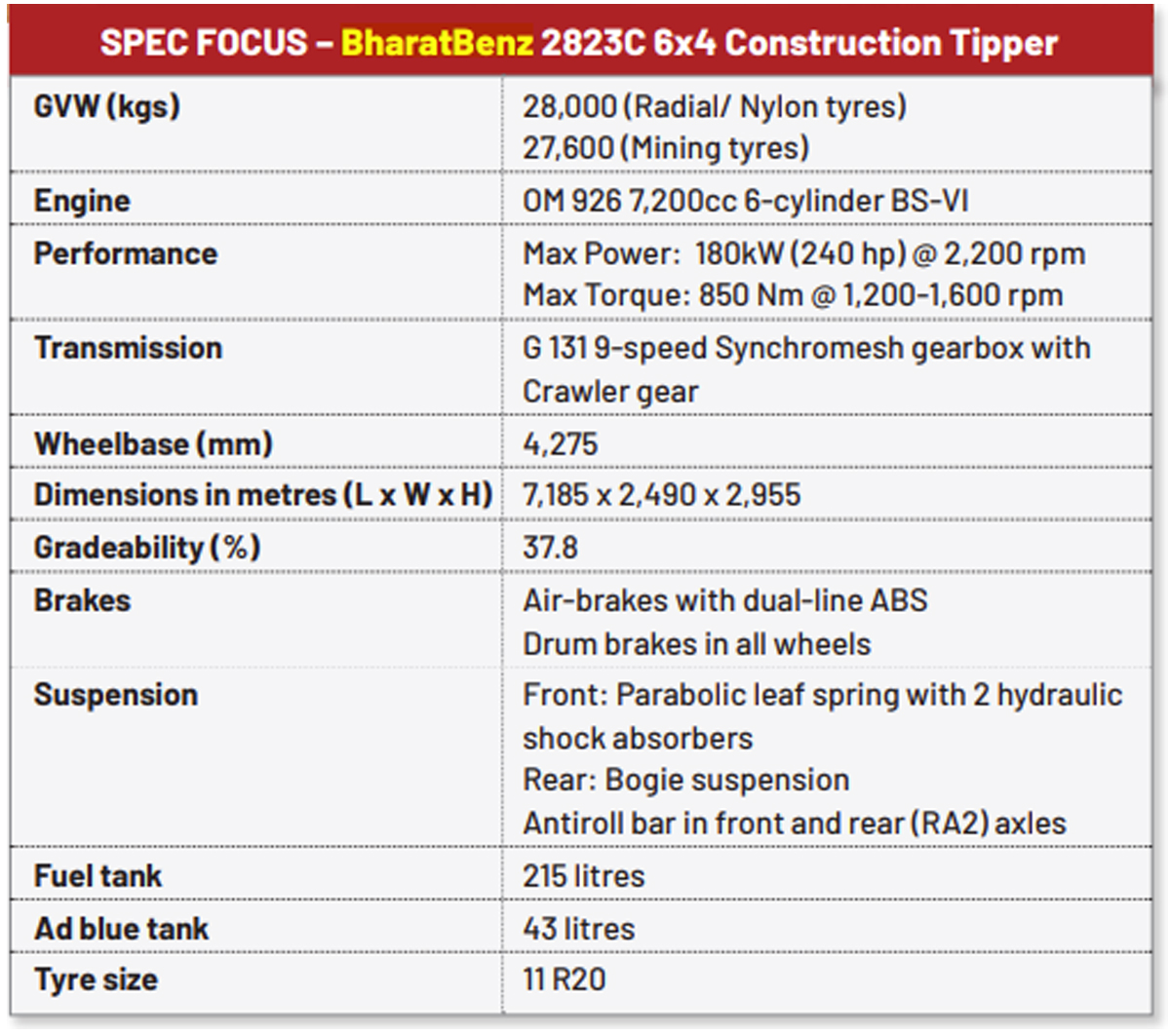

Let’s start with a brief intro about the truck. This is a 28-tonner, twin-rear axle tipper from DICV to woo the customers in the 230 hp class, with quintessential BharatBenz day cab, 16 Cu.m rock body, ‘Truckonnect’ on-board telematics, and so on. The brand’s superior styling aesthetics and cabin ergonomics is something that we are familiar with, so I’m going to quickly fast-forward to the mechanical and driveability aspects of the truck. However, it would be unfair not the mention the absolute pampering of air-suspended seats that simply isolates the driver from any road shocks and the powerful HVAC system that outrightly beats the cooling efficiency of a passenger car. Way to go, BB!

The tipper is mated to a 9-speed synchromesh gearbox with a large 430 mm dry plate clutch with hydraulic control. Larger dia clutch results in better friction, which ensures slip-less transmission of torque in all gears. The 2823C offers a maximum torque of 850 Nm at 1,200-1,600 rpm, making it as one of the torquiest in its class. Fuel efficiency remains to be a top priority in every aspect of the truck design, so the gear ratios are optimized in favour of higher gears, thereby complementing the torque-characteristics in lower gears.

The crawler gear is a real wonder in this truck. This is an essential feature for tipper applications these days, especially when a fully-laden truck is taking steep climbs or descents in a slope. Once engaged, the crawler mode ensures smooth creep with no human touch on either the clutch or brake pedals. The engine doesn’t stall at any point, a big relief for drivers, who can just concentrate on the terrain or maneuvering truck to safety instead.

I was more than surprised to get a first-hand feel of the crawler gear in an undulating path with parabolic pits of 1-3 metres and water wadding scenarios. The tipper crawls in and comes out of the pits with ease in a constant rpm, thereby improving fuel efficiency. Shorter rear overhang, thanks to the bogie suspension setup at the rear axles, along with high front bumper, helps a lot in moving in and out of pits and deeps. Together with anti-roll bars, the tipping stability is also phenomenal.

What is more beneficial is the engine brake. When turned on, the constant throttle valves and the butterfly valves in the cylinder head work in tandem to restrict fuel flow, thereby creating some organic retarding effect. There is also an electronically-controlled exhaust brake flap, which compresses the exhaust flow to create a similar retarding effect. Together with the crawler mode, a fully-laden truck can tackle at least 37 percent grade descents with complete composure, while also preventing unwarranted brake and clutch wear.

Yet another feature that offers the 2823C its dynamic ability is its 2-stage differential lock. The selector on the dashboard comes handy whenever we encounter wheel spin at the rear while driving through slippery roads or slush pools, again a big boon for tippers to keep up their uptime. DICV says the rear axle ratios are also optimized for better gradeability and fuel efficiency.

The 7.2-litre OM926 engine is one of the most refined and responsive engine in this segment. It is rev happy, but doesn’t demand the driver to floor the throttle even in the neediest scenarios. Same is the case with the brake pedal, just a slightest touch is adequately responsive. The steering wheel offers tremendous feedback, while the cabin is well-appointed and noticeably quieter than before.

Some of the other driver-assist systems include the driver state monitoring system to avert his or her distraction or lack of concentration, gear shift adviser and fuel economy tracker in the instrumentation panel, and reverse parking camera system.

With a host of high-spec equipment and premium features, BharatBenz has been transforming the mass-end of the trucking segment in a big way since its inception almost ten years ago. The 2823C construction tipper is no exception and continues to do the same even today. With innovative technologies and value-added equipment list, the tipper strikes the right chord for those buyers who value reliability and TCO more than anything.