Dr. Volkmar Denner, CEO – Robert Bosch GmBH, is bullish about the Indian automotive market. During his recent visit to India, Dr. Denner spoke about the investments made in the manufacturing set-up in Bangalore: “Over the past three years we have invested more than Rs. 370 crores to create this smart campus which is home to over 3,000 out of 18,000 engineers. Additional investments of Rs. 600 crores are planned for further expansion of our set-up here. In terms of new business, last year we set up a state-of-the-art artificial intelligence center here and our newly-established Connected Mobility Solutions division is also active in India.”

Dr. Denner took the opportunity to make many a positive observation about Bosch Group’s heavy investments in the Indian automotive industry to offer an impetus to the Government vision of electric vehicles by 2020.

He said: “To meet the rising demand in the Indian market with tailored solutions and expand India’s strong role in our global network, we will invest Rs. 17,000 million over the next three years.”

It is reported that a major share of the investment will be used to upgrade the Bangalore campus of Bosch by modernizing the manufacturing facilities there.

Mobility, as the game changer

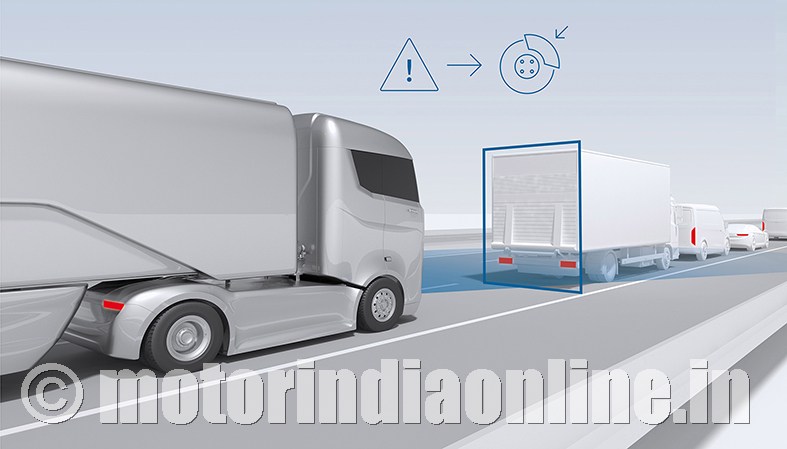

Dr. Denner shared: “The automotive industry in India is moving fast in all technological domains. Bosch Group’s vision for mobility of the future is clear – it is stress-free, accident-free and emission-free which is achievable through automation, electrification and connectivity. To this effect, we are making heavy investments.”

Diesel technology breakthrough

Dr Denner announced with pride: “Our engineers have succeeded in bringing NOx emissions down to a mere 13 milligrams per km in the road test according to the new European RDE standard. This will hold true even in particularly challenging conditions that include stop-and-go traffic, cold weather, and steep gradients.”

He also assured that their new solutions will not make diesel engines become more expensive.

Powertrains

He talked about how powertrain technologies are here to stay, around the world and also in India: “The Bosch Group has invested Rs. 3,195 crores every year since the beginning of this decade in electromobility. Electrification in India is expected to gain momentum via fleet operators for which the pre-requisite is shared and connected mobility. Hence, we believe that it may take-off much more rapidly in small vehicle segments.”

While that is the case, Dr. Denner also assured that Bosch India, in collaboration with OEMs, is ready and geared up to help the industry leap-frog from BS-IV to VI from April 2020 onwards. In the same breath, he feels it does remain a tough proposition. “I think it is far too short a time to prepare for 100 per cent electric vehicles in this time frame because such a scenario requires empowering the country’s electrical grids, and secondly, India needs to build charging infrastructure for all these vehicles. It is a complicated system optimization. One needs to look at the whole value change.”

According to him, the hybrid technology is a vital link which will pave the way to a future with electrification as a solution, while the internal combustion engine will continue to reign supreme for freight and passenger vehicles.

Dr. Denner explained: “We believe the key to making combustion engines more eco-friendly is to use synthetic, carbon-neutral fuels whose manufacturing process captures CO2. This way, the greenhouse gas becomes a raw material from which gasoline, diesel and substitute natural gas can be produced with the help of electricity from renewable sources.”

Connectivity – a crucial solution

“Engineers at Bosch India are currently developing a global telematics platform which offers end-to-end solutions, including integration of mobile network operators, connectivity control unit, development and operation of cloud-based services and smartphone app development and support for back-end solutions,” Dr. Denner said while explaining how Bosch India is harnessing local expertise and working on innovations being catered to the global market.

Industry 4.0 with IoT & AI

Bosch India has added new teams to develop solutions for the IoT to cater to the local needs of factories and cities of future by making them increasingly automated, and connected in line with the Industry 4.0 concept.

Dr. Denner also spoke about Bosch’s Industry 4.0 Academy which offers ‘top-down training to senior executives’ and has already trained more than 250 people.

Of the three centers across the three continents for artificial intelligence established by Bosch, one is in Bangalore. The Group has also set up Robert Bosch Center for Data Science and AI at IIT Madras with an annual funding of Rs. 4 crores for the next five years. He added: “The center will set a precedent in the way big data is used to improve problem-solving capabilities in the industrial domain.”

He also said: “Bosch is already well-positioned in the IoT ecosystem with sensors, software and services. By combining these with AI, we are creating unique value propositions in this domain.”

And the Bosch Group strategy is not to substitute people but make people more valuable by introducing robots.

India outlook

According to the latest global data, Dr. Denner shared: “India has overtaken Germany to become the fourth largest automotive market in the world. In 2017, the Bosch Group registered total sales of around two billion euros in the Indian market, showing a growth of 15.4 per cent in euro terms.

In a nutshell, the Bosch Group expects to continue its momentum of growth in India.