The company’s air suspension system for tip trailers is a boon in terms of notching up better performance while lowering the operational costs

Korba is in the state of Chhattisgarh where coal is everywhere, even in the air. Korba produces over 16% of the country’s coal and is also an electricity hub with 6,428 MW of thermal power capacity. It is a Schedule V district with over 40% tribal population and is highly dependent on the coal industry for jobs and growth. Over 60% of Korba’s GDP and one-in-five jobs are from coal mining and coal-related industries. It has 13 operational mines with four more in the pipeline. As per the current plans of the South Eastern Coalfield Limited (SECL), Korba’s coal production will peak at 180 million tonnes by 2025.

Given this scenario, tip trailers would witness growing demand in the mining segment. As such, BPW Trailers Systems India (P) Limited (BPW India) has identified the potential of transition from traditional or mechanical suspension into air suspension of tip trailers on a pan-India level since 2018. With its strong belief in innovation in critical areas, BPW India took up the challenge to implement its uncompromising air suspension system in the coal mines of Korba and with the assistance of trailer builders such as Indico Motors, Black Diamond Truck Parts and Vandana Trailers and Body Manufacturers it has successfully launched more than 150 tip trailers in the Korba region. “Initially it was very difficult to break the traditional paradigm but it became successful thanks to all our customers who believe in BPW air suspension as a part of their fleet and are willing to upgrade,” the BPW management states.

Bajrang Realcon and Transport Company (BRTC) is one of the companies that have placed strong trust in BPW air suspension. Established in 1998, BRTC has been engaged in coal transportation with a fleet of 150 tip trailers including 40 tip trailers with BPW air suspension. The routes of operations and area of operations are Dipka Mines, Kusmunda Mines and other local mines located in and around Korba. After completion of half a year of operation, the feedback from Yash Kedia, owner of BRTC, has been thus: “I think regular inspections are the most important aspect of vehicle maintenance because they allow us to identify problems before they become major issues. I usually schedule routine inspections every six months, which allows me to check all aspects of the vehicle’s performance. In BPW air suspension’s trailers I found many benefits such as driver comfort and easily replaceable items which save downtime and provide extra tyre life.”

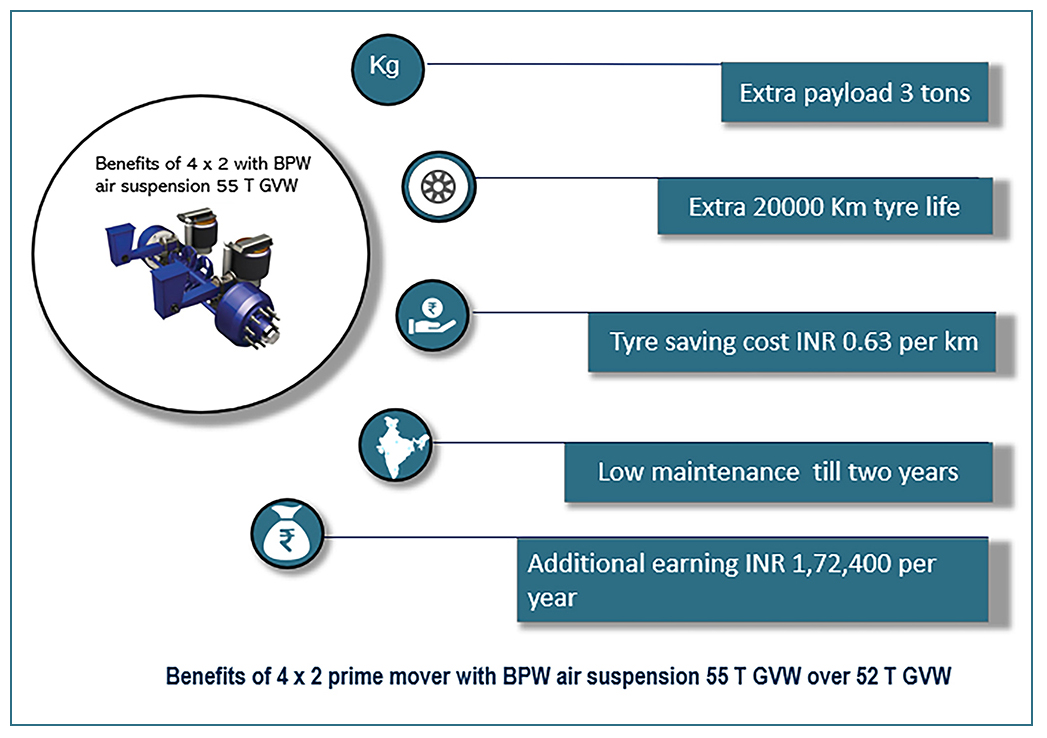

“Also, round-the-clock prompt service is what makes BPW India stand taller than the rest. In a field like coal mining, it is essential to get the repair and maintenance done on time since downtime can lead to mounting expenses. BPW India does score high on that front. Further, we get 9% operational benefits through additional payload and on account of BPW air suspension,” he adds. Kedia is planning to expand the fleet till CY 2022 and has committed to go ahead with BPW air suspension in the future. BRTC manufactured air suspension-fitted trailers initially at Indico Motors, Jamshedpur and Vandana Trailers and Body Manufacturers, Chhattisgarh and would now like to explore more options.