BPW Group is a European market leader in high-quality trailer axles and suspension system for drawbar trailers and semi-trailers. The group’s Indian arm, BPW Trailer Systems India, is making the most of the increasing organised trailer market with its premium offerings, particularly in the area of air suspensions. Rajesh Rajgor finds out more about the company’s operations in the segment in an exclusive interaction with Jens Wilken Johannes, Director, and Nagaraj Ubale, Director – Head of Development, BPW Trailer Systems India (P) Ltd.

Could you elaborate about the impact of the new axle load norms on the market and on your business?

Jens Wilken Johannes (JJ): We are already ahead of the technology that India is stepping into. We are very happy that the government has changed the laws. With the overall approach towards safety, flexibility and progress towards independent trailers, and registering prime movers separately, we understand that India is moving in the right direction. For load increase, we have standard products as well as new products that can adhere to this new weight increase as against merely using the existing axles to load more. In that respect, the interest by fleet operators and trailer manufacturers, who deal with 12-14 tonnes for their daily transport, towards our air suspensions is quite satisfying.

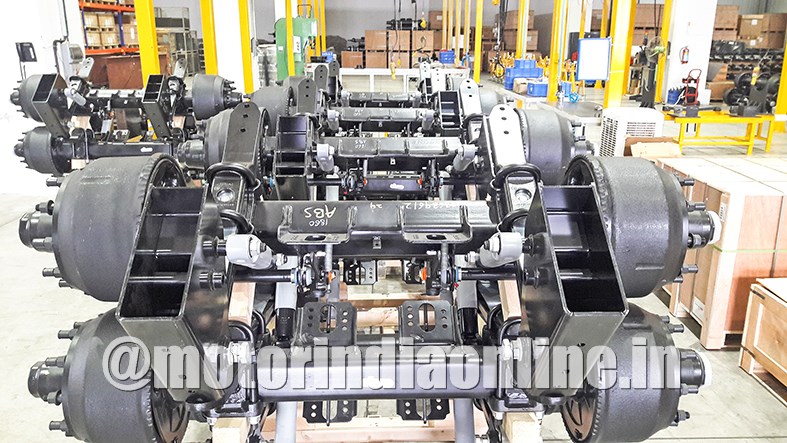

Nagaraj Ubale (NU): After the axle load norms, there was an opportunity for BPW Trailer Systems India to impart understanding about the use of air suspensions. Customers understood that with air suspension one can carry a tonne extra payload per axle and the operator therefore gets three tonnes extra per trailer legally. Needless to mention, our products have performed the best on brake tests carried out by trailer manufacturers, ARAI and ICAT. In fact, we are the only company to have successfully tested and certified our air suspension with brakes as per the new axle load norms even with 55 tonnes load.

What are the highlights of your air suspension product?

JJ: We believe in giving the right technology for the right application. With maximum three air suspension axles in a trailer a fleet operator can save wear and tear to the tyres, brakes and improve fuel efficiency. There is a sensor at the axles that controls the load distribution and if and when the vehicle is empty the axle lifts itself automatically. It goes down when the trailer is loaded optimally.

NU: We are giving 400,000 km of hub greasing intervals, axle beam with 150 mm square cross-section as standard for long life along with rigid and adjustable air suspension hanger brackets with 8 mm wall thickness. This makes great business sense for the large fleet operators and therefore they are increasingly investing in these air suspensions.

What are your standards for quality and how has the market accepted the same?

JJ: Given the superiority we offer, we were able to increase the output significantly; our share of air suspension is meanwhile more than 65% this year despite the slowdown. One of the reasons for our success is our emphasis on selling the entire kit with an axle. We care about the quality we deliver on Indian roads and we focus deeply on the safety and sturdiness of our products. Thankfully, the large Indian fleet operators are beginning to understand the total cost of ownership which has helped us command a market share of close to 60% in the air suspension segment.

NU: As Jens mentioned, we have a quality that is premium for the market, but it is standard for us. Even if there is a request for us to fit an air suspension replacing the mechanical suspension on a competitor’s axle, we deny it as our quality standard does not allow us to do so. Right from the thickness of axle beams to bearings we have the right product to improve performance. We have always been aware of the advantages of the 16 mm square tubular axle beams and therefore it can adapt to various forces coming upon it – be it bending or twisting. It is the driver’s preferred choice too as the air suspension is crucial in transferring sensitive cargo like computers, tiles, gadgets, glass, etc., without causing any damage.

How many variants do you offer currently? How do you handle requests for customized solutions and the service aspect of the business?

JJ: Being a 120-year-old company we have around 40,000 variants and whichever BPW axle a customer decides to fit, we always make sure they drive safely with an effective product. In this regard, although we have achieved 70-75% of localisation here in India for most of the requirements, depending on the volumes – if there is some special variant required – we can easily get it designed and engineered from any of our plants across the world.

NU: When it comes to training, we help customers with initial assembling by being present at their site. Instead of having a large number of service centres across the country, we invest in dedicated service managers who can assist a client at their venue as and when required. These service engineers are trained to support clients with application engineering, especially in order to enhance their product’s experience. This could be from cement, steel, tanker or any other segment; being application-specific is key to our growth. We also supply and offer product assistance in mud guards, lighting system and landing legs, apart from axles and suspensions.