In oder to reduce tyre management cost, New Shalimar Roadways switched to Bridgestone’s Pay-Per-Kilometer solution and adopted 100% Bridgestone tyres for its fleet. Since then, the fleet has experienced 4-5% fuel savings within a year, reports Rajesh Rajgor

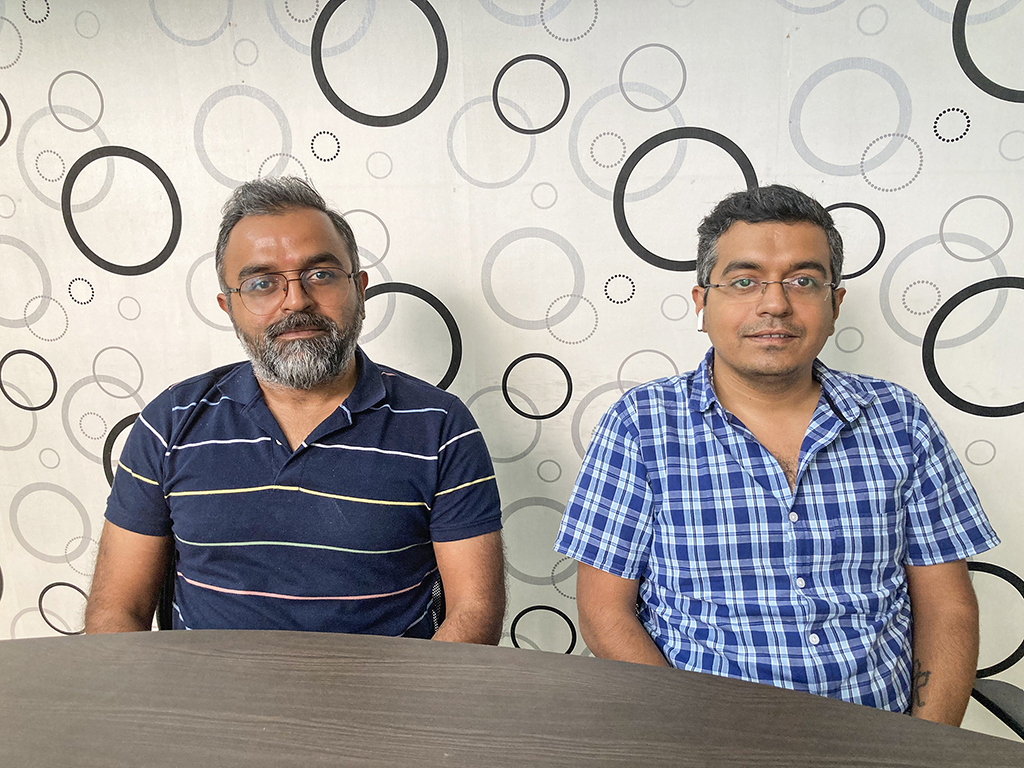

Founded in 1984 by Vijay Kalra, Indore-based New Shalimar Roadways (NSR) is a renowned name in the business of transportation of FMCG goods, white goods, household appliances, automobile components, etc. using containerised trucks. Over the years, NSR has grown into a company managed by a team of professionals. It is currently led by Director Ashish Kalra and Gitesh Kalra with a dedicated team that is committed to responding to customer demands as quickly as possible. Says Ashish: “The logistics business has always been perceived as an industry with a lot of unorganised players. However, contrary to popular notion, we run as a well-oiled engine with each part doing its duty efficiently.”

“We have an organised setup comprising teams with responsibilities of accounts, operations and vehicle maintenance – working like a manufacturing unit,” he adds. This efficiency in operation helps NSR to move their clients’ goods quickly from plants to warehousing locations. A fleet of 170 containerised trucks with lengths ranging from 28 feet to 32 feet and 25 tonnes to 48 tonnes from the stables of Ashok Leyland, BharatBenz, Mahindra and Tata Motors are deployed.

Although the company has a central vehicle maintenance hub at Indore, there is no guaranteed timeline about when a vehicle would return to this hub once it hits the highway. “Even though we have a maintenance yard at our workshop at Indore and AMC with all the truck manufacturers, we opted for Bridgestone for 100% of our tyre maintenance needs. Once our trucks leave from Indore to a destination in South or East, chances are it gets loaded from that destination. Hence, we did not want our truck drivers to stop at any roadside mechanic for issues related to wear and tear. Instead, the pan-India assistance provided by Bridgestone is what appealed us,” explains Ashish.

Amongst the many automotive component manufacturers that are NSR’s clients, Bridgestone has also been a client ever since 2008. While NSR has been using Bridgestone tyres in their fleet, it was the Pay-Per-Kilometre (PPK) solution offered by Bridgestone that convinced them to go full-fledged with the tyre maker. “When Bridgestone shared with us its one-of-a-kind ‘Pay-Per-Kilometre’ (PPK) solution for tyres in September 2020, we found it to be really interesting. Over the course of a few months, it grew into an association that covered all our trucks in stages. Apart from the delivery of best-in-class tyres, the unique features of this PPK solution include dedicated in-house Bridgestone team members who handle and monitor all tyre-management related activities such as kilometre performance, tyre pressure checks and tyre rotation,” elaborates Ashish.

Tyres Matter

The Bridgestone team had done an in-depth study of the fleet’s operations and recommended tyres based on the fleet’s load and road conditions. Ashish reveals: “Since our trucks ply across the Western and Southern parts of the country, it returns to the Indore hub only after 10,000 km. With Bridgestone tyres like M751, R156 TL and G611 tyres, there has not been a single tyre maintenance issue that has come up for us. Bridgestone’s roadside assistance team and network is super-efficient to handle any issue raised by our operational team. We have saved a lot on amounts that we used to shell out to drivers in the name of punctures and repairs.” Apart from the direct saving in the cost of maintenance, the company has also recorded 4-5% savings in fuel consumption.

“We have noted that since Bridgestone tyres rarely fail and come with durable casings, the tyre wear and tear have reduced considerably. The initial tread mileage itself is up to 1,20,000 km and that has translated into improved fuel economy to the tune of 4-5%,” asserts Ashish. NSR consumes 50 tyres every month and is happily assisted by the local Bridgestone team and two personnel deployed at their hub. “The Bridgestone ground team performs tyre inspections on PPK-adopted vehicles for us, as well as data collection and recording of each tyre and wear study, alignment and rotation records and tyre implementation, tyre maintenance and tyre-related issues including replacement of old tyres and ordering new tyres are recommended and performed by the team,” he informs.

Passing on the Benefits

NSR derives confidence from its association with Bridgestone and passes on the benefits it derives to its staff, particularly drivers, and also invests in new vehicles to provide cost-efficient service to its customers. “All that we do and invest in is to earn profit and keep our staff and clients satisfied. With the confidence in fuel savings, improved tyre mileage and practically zero maintenance towards tyres, we have started a ‘raftaar’ program for our drivers. In this model, we expect the drivers to clock 700 km in a day and have had instances where the drivers have surpassed our expectations. Through this program, the drivers get incentivized for their extra efforts over and above their regular salary,” shares Ashish.

NSR is also investing in manufacturing trailers of 45 feet length that can help them carry more voluminous goods. “In order to further enhance our service towards our customers, we are investing in building trailers that can help us carry more goods. This is essential and in tune with the changing times because we need to improve our services. As it is, all our vehicles in the ‘raftaar’ program are less than four years old and the average life of our fleet is seven years; hence, just like we migrated to exceptional quality tyres from Bridgestone, we are investing in prime movers and trailers. Without doubt, we would prefer Bridgestone tyres even in our upcoming fleet of new vehicles,” he reiterates.

NSR appreciates the good initiatives taken by their tyre partner and Ashish is extremely pleased with the overall structure of Bridgestone’s PPK solution. “It is no surprise that Bridgestone’s PPK solution has placed them in an advantageous position in the market. Add to this their far superior tyre quality and capacity to produce and deliver high volumes as per a customer’s demand suits a growing fleet like us. We feel their approach will prove to be a path-breaking one in the Indian transportation industry and immensely benefit logistic service providers like us,” concludes Ashish.

The Bridgestone Impact

• 4-5% better fuel efficiency

• Negligible tyre failures

• Huge reduction in maintenance costs