CNH has commenced production at its new engine plant in Greater Noida, marking a significant step in localization and innovation. The facility manufactures the advanced 2.8L TREM V (F28) engine, designed for high performance, efficiency, and compliance with upcoming emission norms. Rajesh Rajgor spoke with Narinder Mittal, President and MD of CNH India, who highlighted the company’s commitment to India as a key market and global hub. CNH is expanding its dealer network, financing options, and sustainability efforts while strengthening India’s role in its global strategy through manufacturing, exports, and technology development.

CNH, a global leader in agriculture and construction equipment, has now commenced production at its new engine plant in Greater Noida, marking a significant milestone in the company’s dedication to innovation and localization. The facility manufactures the advanced 2.8L TREM V engine (F28), designed to power the company’s product lineup with exceptional performance and efficiency. This cutting-edge global engine has been localized in India to deliver a robust and reliable solution for the Indian market.

For over 25 years, CNH India has been delivering world-class products through its ‘Made in India’ operations. The company operates in the country through its Case IH, New Holland, and CASE Construction Equipment brands, as well as its financial arm CNH Capital and Global Technology Center. With a strong commitment to localization, innovation, and sustainability, CNH continues to strengthen its presence in India, shaping the future of agriculture and construction equipment with cutting-edge technology and strategic investments.

CNH Industrial has been manufacturing engines at its Noida plant for several years, primarily focusing on Tier 3 engines for the local market and exports, particularly for tractors. Until now, engines for tractors bound for the U.S. market were imported. However, with the implementation of the TREM V emission norms set to take effect in April 2026, CNH is preparing to manufacture engines that comply with the new regulations.

TREM V Engine: Advancements & Market Readiness

“The launch of the 2.8L TREM V engine from the state-of-the-art Noida engine plant underscores our dedication to delivering solutions engineered and manufactured in India. This achievement enhances our product offerings and reaffirms CNH’s commitment to innovation and sustainable productivity. This highlights our strategic focus on producing reliable, efficient, and environmentally compliant powertrain solutions that will set new benchmarks for the industry,” Mittal stated.

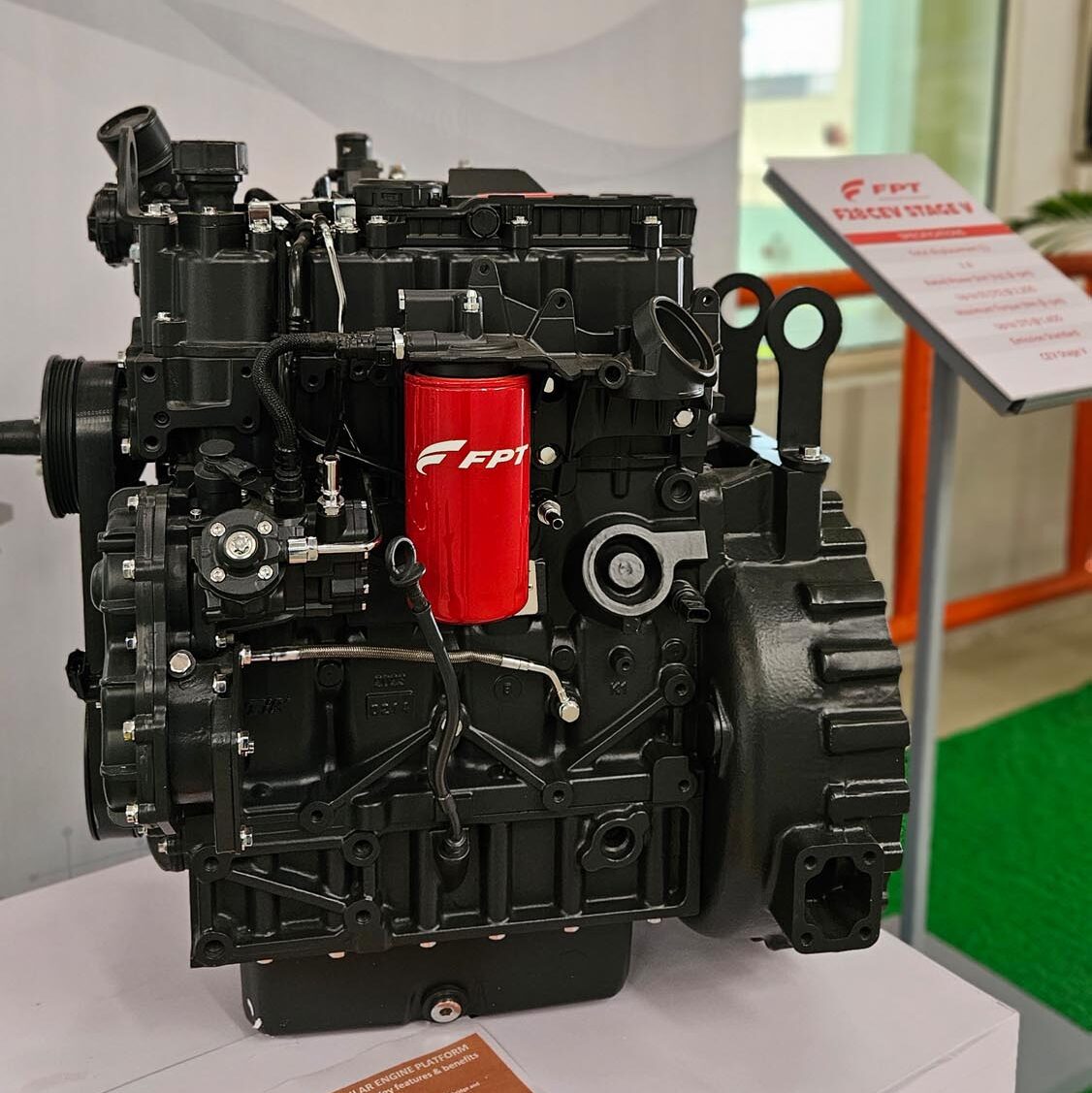

The new 2.8L engine is licensed to CNH by FPT Industrial, the powertrain division of Iveco Group, reflecting the strong synergy between the two entities in driving innovation and sustainability in powertrain technologies. Designed for under-hood applications, its compact design improves engine balance, reduces vibration, and minimizes friction for improved fuel efficiency. Located within CNH’s 60-acre Greater Noida facility, the advanced engine plant spans 7,000 square meters and is designed for scalable production, with an annual capacity of up to 20,000 units.

Currently, the 2.8L F28 TREM V-compliant engine is manufactured for construction equipment (meeting CEV V norms), with plans to expand it to agriculture once TREM V emission norms are introduced. The state-of-the-art plant features digital and AI-driven technologies, including an advanced operator guidance system and robotic component cleaning, ensuring precision, efficiency, and high-quality output.

“The TREM V norms will bring a reduction in particulate matter and NOx emissions. To stay ahead, we launched the F28 engine earlier than some competitors,” said, Mittal. The F28 engine is already being used in construction equipment, with the new emission standards for this segment effective from January 1, 2024.

The F28 is a 2.8L engine designed for high performance, boasting over 25% more torque compared to conventional engines, along with improved specific fuel consumption (SFC). “This engine is not just about power; it’s about efficiency. With better SFC, customers will experience reduced fuel consumption, making operations more cost-effective,” he added. CNH also refers to the F28 as a ‘Green Engine’ due to its adaptability for alternative fuels. With modifications, it can run on gas or be used as a hybrid engine, making it a future-ready powertrain.

The implementation of TREM V norms will naturally increase manufacturing costs due to advanced technology requirements. However, Mittal is confident that the advantages outweigh the additional costs. “While production costs will rise, the improved performance and fuel efficiency will provide a strong payback for customers. The high torque and backup torque of this engine ensure better productivity, reducing operational time in the field,” he explained.

India’s Role in CNH’s Global Strategy

CNH’s presence in India spans over 25 years under the New Holland brand for agriculture and the CASE brand for construction. However, its roots in India go back to 1969, when Ford and Escorts formed a joint venture. Recognizing India’s economic growth and market potential, CNH has recently established India as an independent business region, separate from its four existing global regions. “India’s position as the world’s fifth-largest economy and its rapid growth prompted us to create a dedicated region, allowing focused investments and strategic expansion,” revealed Mittal.

The company’s growth strategy in India rests on four pillars. The first is serving the domestic market by manufacturing in India for India. The second pillar is leveraging India as a global manufacturing hub to expand exports. “We see significant potential in exporting from India, given our expertise and production capabilities,” he noted. The third pillar is the India Technology Center (ITC), where over 600 engineers work on designing products not just for the local market but for CNH’s global portfolio. The final pillar is strengthening India’s role in the global supply chain. With India exporting over $178 billion worth of components annually, CNH aims to enhance its sourcing from Indian suppliers to support global operations. “We are already sourcing components for global products, but our goal is to scale this up significantly,” he said.

Strengthening Reach, Enhancing Access

CNH is also focusing on expanding its dealer network in India. “We have been strong in certain markets but need to increase our reach. Our aim is not just expansion but also making the network more effective by providing advanced technology and global best practices,” Mittal emphasized. The company is committed to enhancing customer experience through improved reliability, seamless purchasing, and better after-sales support. It closely monitors its Net Promoter Score (NPS) to measure customer satisfaction and continuously refine its offerings.

Financing plays a crucial role in CNH’s growth strategy, and the company established CNH Capital in 2018 to support wholesale and retail funding. “CNH Capital has achieved nearly 26-27% retail penetration. However, we also work closely with non-captive financers such as NBFCs and banks to provide diverse financing options for customers,” he explained. CNH aims to expand CNH Capital’s penetration while ensuring a balanced coexistence with external financiers.

Sustainability & Environmental Commitment

Sustainability remains a core focus for CNH in India. The company is actively supporting government initiatives to promote stubble bailing solutions, reducing the environmental impact of crop residue burning. “We are introducing advanced bailing technology to help farmers repurpose stubble for gas and power generation,” Mittal said. In manufacturing, CNH is increasing its reliance on solar power. “Our Noida plant already uses solar energy, and we are expanding similar initiatives in Pithampur and Pune,” he added. Additionally, CNH is introducing larger 200 HP+ tractors in India, all of which comply with TREM V norms, reinforcing its commitment to sustainable technology.

With a strong foundation in India, CNH is positioned for long-term growth, driven by innovation, strategic expansion, and sustainable practices. “Our focus is on leveraging India’s strengths to grow the business domestically and globally while ensuring technological advancements benefit our customers,” Mittal concluded.