AVTEC Ltd., one of the largest independent manufacturers of powertrains and precision engineered products in India, has added yet another world class product, the transfer case, to its vast and varied portfolio catering to growing industry requirements.

The product adds a significant dimension to AVTEC’s growing business by offering customized solutions for automotive and off-highway requirements, synergised to its current manufacturing and development strengths.

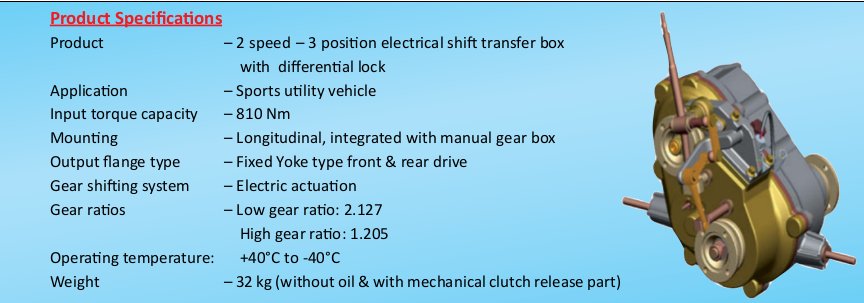

The product is offered in the input torque range of 800-2000 Nm, actuated through manual / electric shift mechanism, including the torque activation “on-the-fly” and “torque-on-demand” with features like torque limiting clutch. These designs are adaptable to suit customer-specific engine / driveline configurations.

As a first step towards product development, the company is jointly working with a reputed global OEM to design and develop a gear-driven transfer case for sports utility vehicles (SPVs). An all-weather product under development, it gives the user a distinct advantage of superior torque distribution and management system.

The rich experience of working with various technologies like those of Isuzu, GM, Ford, Daimler, Allison, etc., coupled with the design expertise, has helped AVTEC in the development of products and vehicle homologation.

AVTEC’s transfer case is known for its completely indigenized design and manufacturing system suitable for commercial vehicles, off-highway equipment and tractors. Adaptable for extreme weather conditions, it is cost-effective, with good local parts supply support.

Design capability

AVTEC has established a technical center at Hosur for design and development of unique customized and off-the-shelf products for powertrains to cater to the growing industry requirements. The center is a self-sustained facility equipped with the latest modelling and design analysis tools such as Nastran, Hypermesh, Unigraphics, Romax Gear Train Design Software, Matlab, etc.

By virtue of having an in-house proto manufacturing facility, quality laboratory, test rigs and a strong team of more than 30 design and application engineers, the company is able to provide faster design & development of prototype samples while maintaining the confidentiality of the designs for specific customers.

AVTEC has acquired the Swiss-based ASSAG, a world leader in drive systems and face gear technology with its design and assembly facility in Switzerland and a manufacturing facility in the Netherlands. Its technology and products are being used by major global players in areas like automotive, machine tools, industrial, aerospace, etc.

ASSAG design prowess supplements AVTEC strengths in application engineering, manufacturing, material development and high volume production to provide customers high technology solution at competitive rates.