Dana is the only top-tier supplier that serves all three major vehicle markets – passenger vehicle, commercial truck, and off-highway. This unique position allows Dana to leverage its technology, processes, and assets across all these end markets, providing its OEM customers with a competitive advantage by enabling us to bring products to market faster. Mr. Marcus King, Senior Director of Off-Highway Operations – Asia Pacific, Dana Incorporated, shares details about the company’s operations in the domain and the recent developments.

Excerpts:

Indicate the earthmoving segment focus areas & the axles/transmission assemblies supplied for the applications. What are the USPs and your plans to increase the market share in a competitive market?

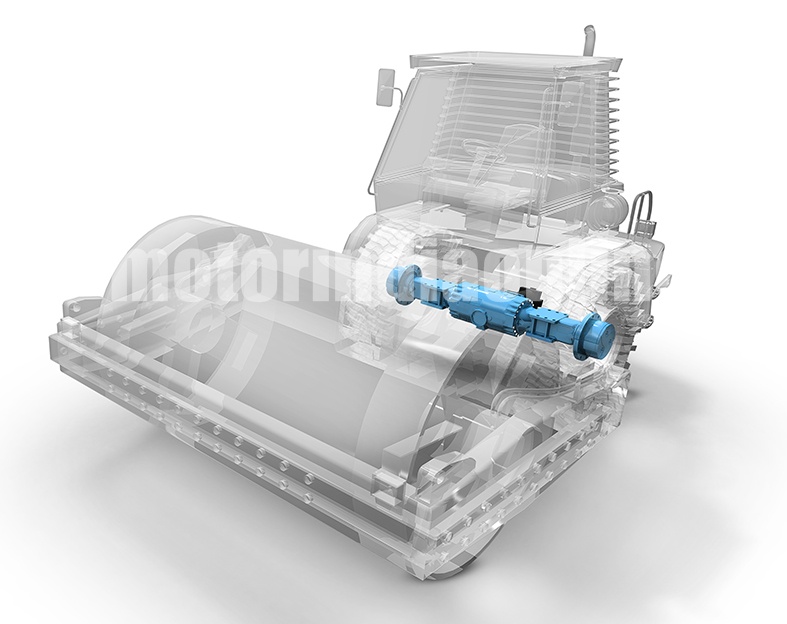

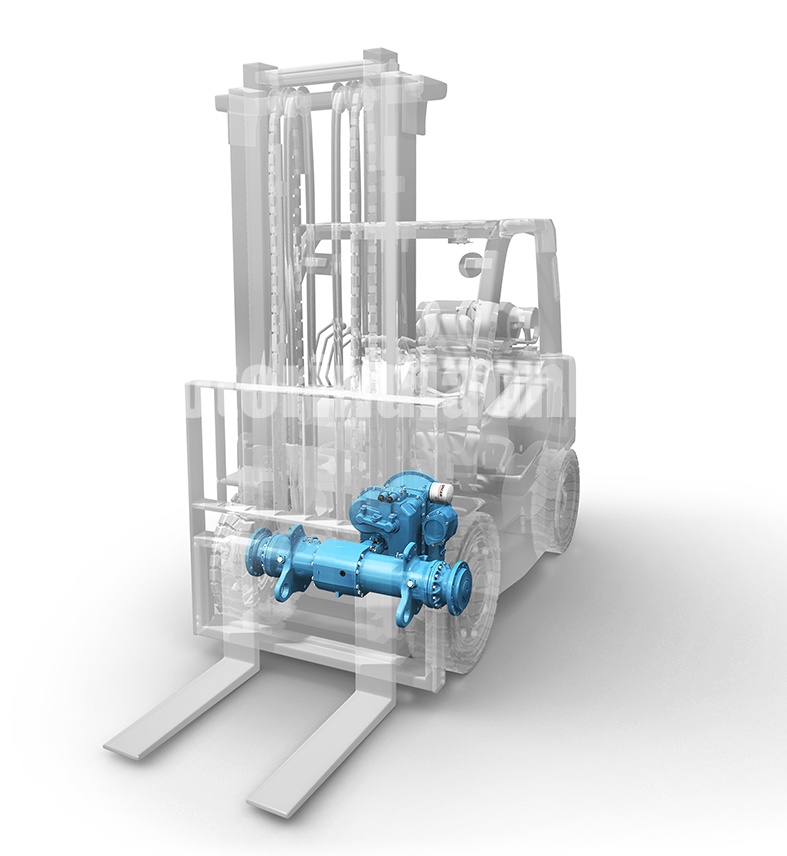

For many years, Dana has offered a full range of complete drivetrain solutions – including transmissions, axles, and driveshafts – for a variety of earthmoving and construction equipment, including wheel loaders, wheeled excavators, motor graders, and single drum rollers.

Dana’s unique selling proposition for the market has long been our ability to deliver complete integrated drivetrain solutions to original-equipment manufacturers, as well as our expertise in developing solutions that meet specific local demands by utilizing our global engineering resources and our portfolio of proven technologies.

One of Dana’s efforts to increase market share includes the recent acquisition of the power-transmission and fluid power businesses of Brevini Group, S.p.A., which closed on February 1. By purchasing these assets of Brevini, Dana will be able to supply off-highway driveline systems for tracked vehicles, such as dozers, track loaders, and track excavators.

The purchase of Brevini also immediately expands Dana’s product portfolio and establishes us as the only solutions provider that can manage power conveyance to move machines and also perform the work functions of the machine.

Ultimately, the purchase enables Dana to increase the amount of content we supply on any given machine.

Brief us the type of co-operation with OEMs in developing the components for their application. Also indicate if the inputs for product design and development are provided by OEMs or arrived at after detailed application studies and field trials.

Close collaboration with OEMs is critical in developing solutions, which is why Dana has strategically positioned 16 global technology centers around the world, including an 8,000 square-meter facility in Pune, India that is home to more than 240 engineers.

Devoted to the research, design, development, and testing of drivetrain, sealing, and thermal-management products, the Dana India Technical Center is fully integrated into Dana’s global research and development system to support new products from concept development through launch, as well as to adapt technologies developed elsewhere in the world for the specific needs of the Indian market.

The center combines design, finite element analysis, and testing for all of Dana’s product groups under one roof. It includes an electronic controls lab, a testing area, a materials development lab, a prototype area, and an NVH and performance analysis lab for product development.

The new lab in Pune features the latest testing equipment for axles, transmissions, materials, NVH, prototyping, inspections, and machining to ensure that products engineered and manufactured by Dana in India meet the company’s highest standards for performance and durability. This equipment includes dynamometers, a rotating bending test stand, a beam fatigue test stand, a multi-axis spin stand, rotary actuators, and linear actuators.

The location of our technology center close to our customers in India facilitates the development of solutions, and our long history of developing solutions for the off-highway market provides our customers with a wide and readily available portfolio of proven technologies. Our engineers rarely need to design components from scratch for Indian OEMs. In the vast majority of cases, we already have a solution that closely matches our customers’ requirements, and our engineers in India only need to make minor modifications.

Against the arduous operating conditions for the machines, what special design features are considered and provided for reliability and safety factors? Brief us the R&D facilities, operations & the endeavours in launching new products for applications.

Dana currently delivers numerous design features that are focused on performance, reliability, durability, and serviceability.

For example, Dana supplies a variety of differentials to ensure mobility, and Dana offers axles with no-spin, limited-slip, Posi-Torq, and Hydraloc differentials. Dana’s Spicer axles also accommodate a wide range of vehicle weights, tracks, tires, and chain combinations.

Brakes are also critical for performance and safety, and Dana offers axles that can be equipped with foundation service brakes, inboard and outboard wet disc brakes, and a spring-applied hydraulic release (SAHR) parking brake.

While multiple differential and brake options are fairly common, Dana is looking to the future by developing Spicer Smart Suite technology packages, a platform of fully integrated, connected-vehicle features that converts operating data from the drivetrain into actionable insights for enhancing productivity, improving operator and machine safety, reducing maintenance costs, and decreasing total operating costs.

The first package to be released – Spicer Smart Suite ILMS – is designed to alert telehandler operators of potential tipping situations, reduce the risk of vehicle breakdowns, improve efficiency and precision, and enhance the long-term durability of powertrain systems. A 2018 production date is anticipated for Spicer Smart Suite ILMS.

Provide us the details of aftermarket business and its contribution share in your sales revenue. How do you compete with local and imported supplies for the non-proprietary spares?

The value we deliver to equipment owners in the aftermarket is closely aligned with the same value we offer to original-equipment manufacturers in the areas of performance, reliability, and durability. Genuine Spicer service parts are manufactured using superior metallurgy, hobbed and shaved gearing, and precision heat-treating and shot peening processes to ensure consistent quality and exceptional durability.

Dana engineers then subject Spicer parts to rigorous testing. Evidence shows that genuine Spicer original-equipment products can last up to ten times longer than non-genuine replacement parts.