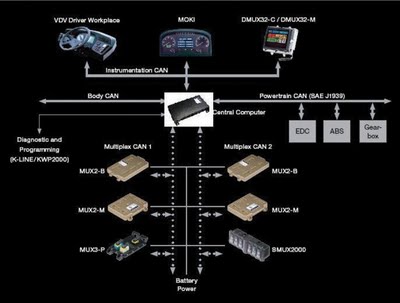

Continental Automotive is gearing up to offer multiplexing solutions for onboard electronics to major OEMs in the commercial vehicles segment. Multiplexing with KIBES will provide benefit in the form of optimized wiring and electrical distribution, thereby providing vehicle cost saving due to reduced wiring harnesses, connections, relays & fuses, as well as less vehicle weight and installation time. By reducing the wiring loom and virtually eliminating all fuses and relays, the multiplexing system increases reliability and reduces installation complexity. Currently third generation technology KIBES is in the market. The entire multiplexing architecture works on CAN network.

Bus and other special vehicle requirements are more and more dependent on enlarged functionality, efficiency, reliability and comfort. Reliance on Continental KIBES multiplex system means using a cost-optimized and scalable platform solution in vehicle – ideally designed for all sorts of vehicle volumes. All components are available off-the-shelf to enable a short time-to-market introduction. Benefit from the European market leader with over 15 years experience, like more than 30 other major customers all over the world. Continental continuously improves and enhances the multiplex system according to customer, market and legal requirements.

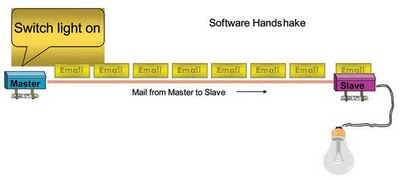

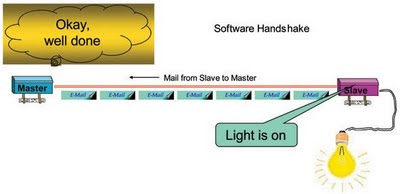

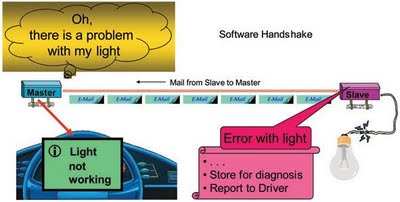

The main end-customer benefits are reduced downtime due to quick diagnostic checks; on-board diagnostic (OBD) offering quick and easy solution to problems, which can be transmitted (remote or by phone) to the next service station; vehicle information on demand, useful info for driver and service; improved quality, and higher fuel efficiency. Some functions which were expensive earlier can now be easily provided. “Electronic fuses” will replace the traditional one. With no replacement of broken fuses, the customer is happy with no need for search for correct fuse. Less relays means higher reliability and a happier customer. With functional upgrade by SW update, failure report on priority means no overload by insignificant warnings.

Some functions which were expensive earlier can now be easily provided. “Electronic fuses” will replace the traditional one. With no replacement of broken fuses, the customer is happy with no need for search for correct fuse. Less relays means higher reliability and a happier customer. With functional upgrade by SW update, failure report on priority means no overload by insignificant warnings.

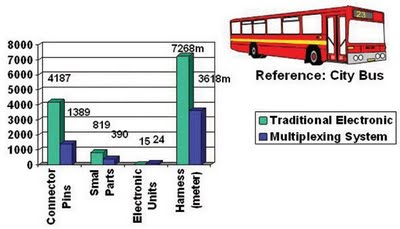

The OEM benefits are equally significant. Every reduction of another ECU (e.g., HVAC or door control on buses) and replacement of an ECU, by e.g., CBCU / CMIC-display reduces the cost. Faster production process means reduced cost. Reduction in wiring harness results in less weight and reduced cost, savings in dash harness (between cluster – E/E box), and savings on chassis (only if distributed power nodes are used). Increased quality in production process (quicker and better) implies reduced cost and improved vehicle reliability.

Reduction in wiring harness results in less weight and reduced cost, savings in dash harness (between cluster – E/E box), and savings on chassis (only if distributed power nodes are used). Increased quality in production process (quicker and better) implies reduced cost and improved vehicle reliability.

Platform architecture over all classes of trucks & buses leads to less components (less cost in purchasing, logistics, stock, service). All sensor data will be shared within the network. Multiple sensors to be connected on different units are no more required (e.g., there is only one outside temp sensor).

Once measured, values can be used by all connected ECUs and also displayed for the driver. Production & service

Production & service

Reduced wiring = less connectors = improved vehicle quality and happy customers. Every connector is a potential fault source. Smaller harness is easier to mount with less undetected pre-damages, and less wires out of the cabin means better water protection to the cab.

Using end-off-line (EOL) programming, the CBCU/BCM can be customized according to the vehicle specifications. Different types of vehicles or options can be activated within the application program or by setup of parameters. Improved quality in production process (quicker and better) means reduced cost and higher vehicle reliability.

Improved statistical information on vehicle life performance facilitates assessment for future vehicle enhancements at the component level. Preventative maintenance leads to reduced vehicle breakdowns and cut in costs. Direct assessment of quality claims leads to reduction in false claims and reduced warranty costs. Currently Continental is world leader in multiplexing solution with its adaptability to different markets and with its scalable platform products. Its main customers worldwide include MAN, Daimler, Iveco, Volvo, DAF, Paccar, Tata Motors, Ashok Leyland, etc.

Currently Continental is world leader in multiplexing solution with its adaptability to different markets and with its scalable platform products. Its main customers worldwide include MAN, Daimler, Iveco, Volvo, DAF, Paccar, Tata Motors, Ashok Leyland, etc.

The normal lead time for truck development is two-third years with requirements, features and options dynamically changing over this period. Continental uses flexible model-based application program like PLC which provides more independency between hardware and functionality, whereby functionality is covered by application software.

The vehicle networking & multiplexing technology is new to all the Indian customers of the company, and the challenges will be tremendous in the introduction phase. According to experience in the European market, there was a learning curve not only for development but for production, service and marketing as well.