The certification comes much ahead of the new emission norms for wheeled equipment slated for April 1, 2021

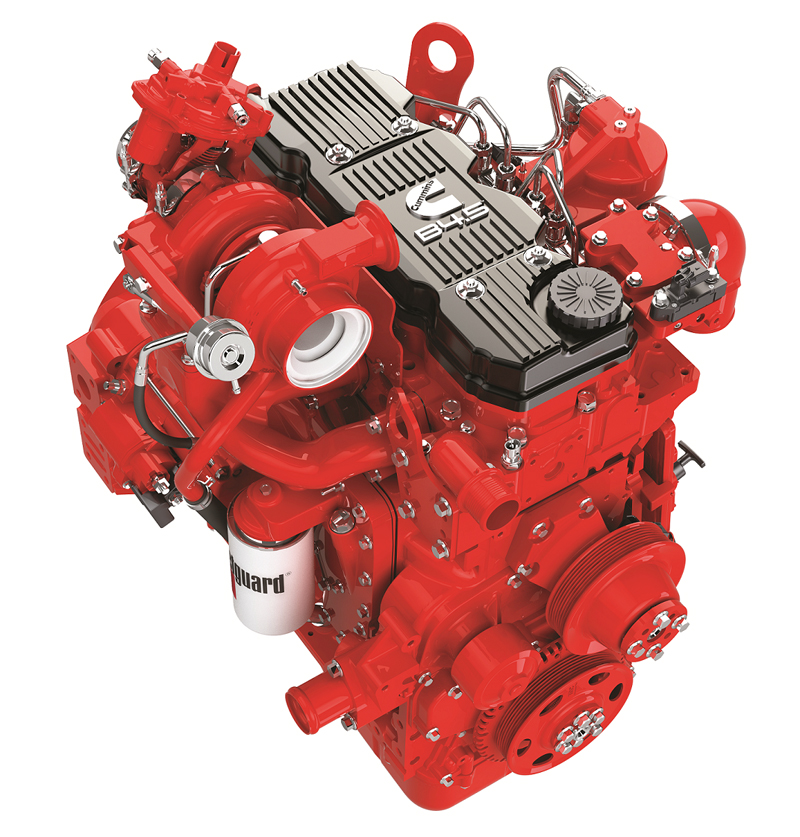

Cummins, the largest independent manufacturer of engines, after-treatment, turbo for industrial equipment, commercial vehicles and also power generators in India, has successfully completed BS IV (CEV) emission standard certification tests for its state-of-the-art 4.5 litre engine system at the International Centre for Automotive Technology (ICAT). This is much ahead of the new emission norms’ implementation deadline of April 1, 2021 for wheeled equipment, as for example, wheel loader, backhoe loader, compactor, harvester, paver, etc. This product can easily be scaled up to BS V emission norms and beyond.

Commenting on the certification, Ashwath Ram, Managing Director, Cummins India, said: “Cummins’ mission is to make people’s lives better by powering a more prosperous world. The ‘prosperous world’ requires a vibrant, healthy planet. As India looks to boost its economy through infrastructure growth, we are all set to evolve from mechanical to new generation fully electronic engine systems. These new engines systems will be powered by Cummins’ best-in-class, globally-proven technology and will ensure higher uptime, better TCO, easy installation and cleaner emissions and hence will deliver superior value to end-users.”

Anjali Pandey, Vice President (Engine Business and Components Business), Cummins India, added: “Tough jobs demand tougher equipment, and no one makes tougher construction engines systems than Cummins. Our construction engines are known for their durability and reliability, producing more responsive power delivery with minimal maintenance costs, thus translating to maximum uptime and best TCO for our customers. This new four cylinder, 4.5L CEV BS IV-compliant engine system will further help us enhance our presence in the construction segment while meeting stringent emissions standards and providing value to our customers.” Globally more than 1 million Euro 6 or BS VI equivalent and higher emission vehicles are running with Cummins engine and after-treatment system. Cummins is also vertically integrated with the capability to design and manufacture critical engine and after-treatment components and sub-systems. Cummins’ engines and engine-systems are enabled with connected solutions for optimised performance at all times and easy prognostics and diagnostics. Cummins is committed to innovate and produce products that reduce carbon footprint.