Cummins Inc. will reveal a medium-duty concept truck powered by the B6.7H hydrogen internal combustion engine (H2-ICE) at the IAA Transportation exhibition (Sept. 20 to 25, Hanover, Germany). The H2-ICE conversion highlights the opportunity for truck applications across the 10-to-26 ton gross vehicle weight (GVW) range to operate on zero-carbon hydrogen fuel with a potential operating range of up to 500-kilometres.

“The H2-ICE concept truck on show at IAA puts Cummins at the forefront of this rapidly emerging internal combustion engine technology using zero-carbon hydrogen fuel,” said Alison Trueblood, Cummins Executive Director – On-highway Business Europe.

“While Cummins hydrogen fuel cells offer a highly effective solution for specific applications within the truck industry, our hydrogen engines can also help accelerate fleet decarbonisation by offering a lower cost basis using more familiar engine technology,” Trueblood continued.

The Cummins H2-ICE project utilised a Mercedes-Benz Atego 4×2 truck, representing a versatile and widely used vehicle for multi-drop distribution haulage. The hydrogen conversion work does not compromise truck performance, cargo capacity or payload.

The proof-of-concept installation is rated 290 hp (216 kW) and features a 700-bar pressure high-capacity hydrogen storage system.

The seamless substitution of the diesel engine with the 6.7-litre hydrogen engine and integration with the existing driveline highlights the ability of H2-ICE to offer a zero-carbon solution for fleets based on a lower cost and a more easily deployable technology path.

Technical development work on the H2-ICE concept truck was undertaken by the Cummins team at the Gross-Gerau facility in Germany, working in collaboration with vehicle engineering specialists, the EDAG Group.

“The introduction of H2-ICE powered trucks over the shorter term can help develop the hydrogen fuel infrastructure to bridge the way forward for the wider adoption of fuel cell electric vehicles. In this way, hydrogen engines and fuel cells are complementary technologies, working together to drive the hydrogen economy forward,” added Trueblood.

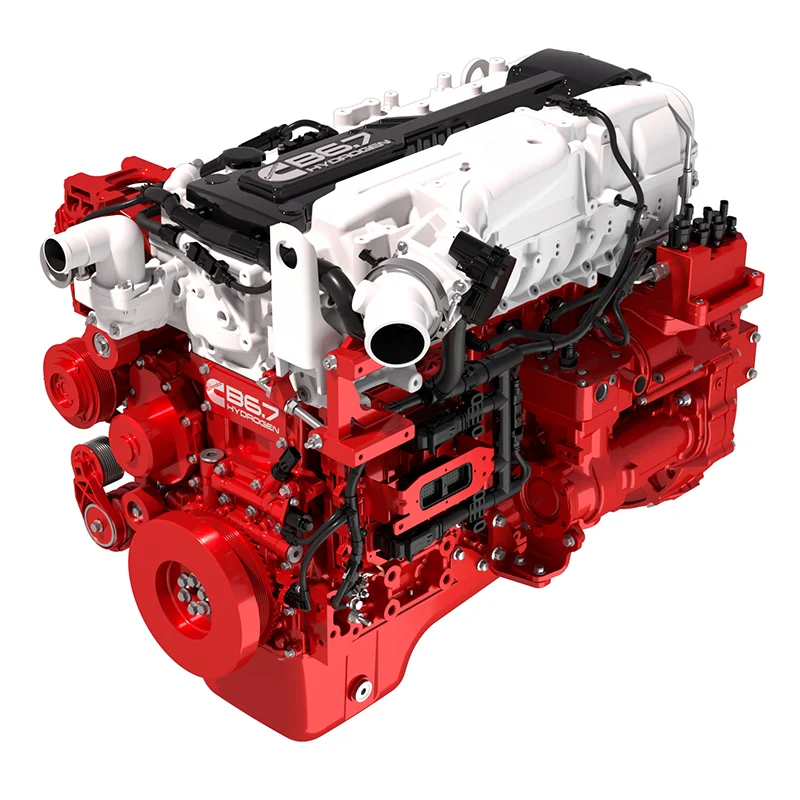

The B6.7H hydrogen engine with up to 290 hp (216 kW) output and 1200 Nm peak torque is an all-new engine platform featuring cutting-edge technology to enhance power density, reduce friction losses and improve thermal efficiency. As a result, performance is equivalent to that of a similar displacement diesel engine and compatible with the same transmissions, drivelines and cooling packages. A further benefit of the B6.7H is significantly quieter running than a diesel.

Jim Nebergall, Cummins General Manager – Hydrogen Engines, commented, “Cummins continues to receive strong global market interest in H2-ICE. The excitement is evident in recent intent to order announcements from major U.S. on-highway operators Werner Enterprises and Transport Enterprise Leasing (TEL) as well as from agricultural tractor manufacturer Versatile. Momentum is growing for this practical decarbonisation technology and I am sure this will be further reinforced at the IAA expo with our H2-ICE truck conversion set to attract major attention.”

High-Capacity Hydrogen Storage

Cummins partnership with hydrogen storage specialist NPROXX provided an important resource in terms of integrating the hydrogen tanks, operating at a higher 700-bar working pressure to increase the fuel storage capacity. The chassis accommodates twin fuel tanks with a total capacity of around 40 kg of hydrogen, together with an installation space remaining available for an auxiliary tank of around 10 kg.

The hydrogen tanks are structurally reinforced with carbon fibre to provide a superior strength-to-weight ratio. High-capacity fuel storage, combined with the energy efficiency of direct-injection learn-burn combustion enable the B6.7H powered truck to offer a potential range of up to 500-kilometres, sufficient for most medium-duty trucks and significantly more than an electric-battery powered truck of a comparable size.

A Cummins-designed fuel control module brings together the hydrogen fuel refill point, the fuel filtration and fuel distribution system in a single unit with easy access. Refilling the truck with hydrogen gas fuel is estimated to take just 10 minutes. The development of H2-ICE technology expands Cummins carbon-free technology portfolio, adding to the company’s capability in hydrogen fuel cell power, battery electric systems, renewable natural gas powertrains, e-powertrains and green hydrogen production from PEM electrolysers.

Fuel-Agnostic Platforms

The B6.7H hydrogen engine will be joined on the Cummins display at IAA by the X15H hydrogen engine, offering the potential to bring zero-carbon hydrogen power to long distance trucks of up to 44T GVW, with a top rating of 530 hp 395 kW) and an impressive peak torque of 2600 Nm. A heavy-duty truck featuring a high-capacity hydrogen fuel storage system and powered by the X15H is estimated to offer a potential operating range of over 1000 kilometres.

The next generation 15-litre follows the 6.7-litre engine in being derived from Cummins fuel-agnostic platform offering the benefit of a common-base architecture and low-to-zero carbon fuel capability, with advanced diesel, natural gas and hydrogen variants.