Dana India is looking to widen its portfolio of drive axles with a broader range targeted at medium and heavy commercial vehicles. The company plans to introduce axles in the segments where it is not currently present.

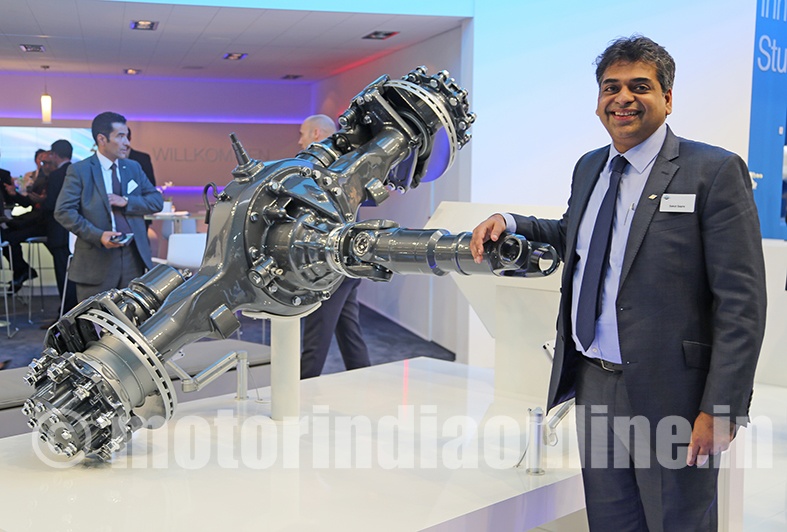

“We will be launching axles to cater to the demands of the 35-tonne and above applications, and also products to cover the 9 -14 tonne segment. This will not only expand our product portfolio but also expand our customer base,” reveals Mr. Saket Sapra, Managing Director, Dana India. “Our company is focused on best-in-class quality, reliability of products as well as an increased emphasis on safety and best-in-class manufacturing”, he adds.

When Dana India fulfills its plans, the company will offer a light-weight axle (an improved version, based on an existing proven design for the 25 to 31T segment) by the end of 2016 and three more new axles by the end of 2017.

“When we speak of introducing new axles, we do not simply mean adding additional gear ratios to widen the scope, but launching completely new, best in class axles, designed specifically for the Indian market and what our customers need. We are also looking into introducing a heavy-duty tandem axle for mining tipper applications and the 49-Tonne and above tractor applications, and the requirements and timelines for the same are being worked upon presently”, shares Mr. Sapra.

All initiatives are backed by the Dana India Technical Centre in Pune. It reinforces Dana’s commitment to India, and enhances Dana’s ability to develop technologies and products for India with faster turnaround times – designed in India. At the same time, this center is fully integrated into Dana’s global R&D network, and is one of three centers globally that engineers Dana products for all markets.

‘Glocal’ solutions and partnerships

It is an accepted principle that importing extensively is not ideal for any company who is aiming to provide better, competitive and customized solutions for customers. Dana India has achieved 100 per cent localization in solo axles and is working in the direction to implement 100 per cent local content in tandem and all future axles. Another aspect that will further boost business in India is the focus on exports and aftermarket.

As far as the aftermarket is concerned, he explains: “Being aware of our current penetration, we are ramping-up our distribution to ensure cost-effective availability and delivery to grow our regional penetration, while providing hands-on service and support.”

As OEMs are continuously introducing new vehicles and variants, Dana India recognises the need to partner with them to offer customized solutions, especially to meet future regulations and trends. “Going forward we need to partner with OEMs and be nimble to make customized products. These products could be products like twin-speed axles, axles for electric vehicles, tyre management systems or even lighter and more durable propshafts,” he believes.

Dana India Pvt. Ltd. and the Dana India Technical Centre in Pune are two 100 per cent subsidiaries of Dana Incorporated. Dana India Pvt. Ltd. has two M&HCV drive-axle facilities and one off-highway facility dealing with the agriculture and construction sector. Light vehicle axles for the commercial and passenger segment as well as the propeller shaft business is under the aegis of Spicer India. “Our JV partners include Spicer India Pvt. Ltd. with Anand Group and Victor Reinz India Private Ltd. with the Jayant Group. We also have another JV, Axles India Ltd., producing axle housings”, concludes the MD.