The new buzz in Indian bus market

The Indian bus market has seen a remarkable transformation over the last decade with the advent of multinational bus manufacturers. There has been an evolution of a separate luxury segment catering to the premium travellers though its penetration has been less than one per cent out of the total annual bus market of over 80,000 buses. Deccan Auto Ltd., a company floated by Mr. M.S.R.V. Prasad, an NRI, and his partner, Mr. V.A. Norhi, aspires to raise the bar in the Indian bus industry with a range of buses developed to suit the requirements of the Indian passengers.

The company is setting up a greenfield manufacturing facility over 130 acres near Patancheru, near Hyderabad. The plant, which will have an annual production capacity of 3,000 buses, is nearly up and running and is expected to begin trial production by April. It will be equipped with state-of-the-art machinery and technology and will be amongst the most modern bus manufacturing facilities in the country. Certification of Deccan Auto’s chassis by ARAI is already underway and is expected to be completed in the next few months.

Says Mr. V.A. Norhi, Managing Director, Deccan Auto Ltd.: “We need to move away from today’s ‘standard’ bus to the ‘real’ bus. The market for ‘real’ buses in India is very large.”

By ‘real’ bus, Mr. Norhi refers to the rear-engine buses as compared to the ‘standard’ ones built on front-engine chassis. Despite the huge numbers, the Indian bus market is still dominated by the standard front-engine chassis which are typically truck chassis.

Over the last decade, the adoption of luxury bus travel has grown steadily which has brought about a revolution in the Indian bus industry. “Today, high-end luxury buses are becoming a matter of convenience in travel than a few years back when it was a matter of luxury”, says Mr. Balaji, Director, Synergy Management Advisors Pvt. Ltd., and Principal Advisor, Deccan Auto which has its sights on the growing luxury segment in the country and also has a super luxury product in its range.

Chinese technology

The Deccan Auto Group has taken just 18 months to go from conceptualization to production. The whole idea was born in October 2011, and once the promoters were convinced about the requirement of the right kind of buses for the Indian market, things fell in place quite seamlessly. The first nine months involved extensive travel by the Deccan Auto team to visit various bus manufacturers abroad to get an understanding of the type of buses that would suit a market like India.

“We visited more than a dozen bus manufacturers and many bus operators as well to ascertain the kind of buses that would be apt for Indian operations. We had invited private customers from India like VRL Logistics to visit the foreign bus manufacturers to have a deeper study of the vehicles”, says Mr. Balaji, who has been the king-pin of the project. The company has ensured that the customers’ suggestions were taken into account while designing buses.

“Mr. Anand Sankeshwar, Managing Director of VRL Logistics, had suggested some important changes in design during his visit to one of the manufacturers abroad. We have made sure the changes are incorporated in our vehicles”, he comments with a smile.

The delegation from VRL included Mr. Bhatt who is the Chief Technical Officer and an important driving force behind the success of VRL’s operations. Mr. Bhatt had also made some important comments on the product specifications and configurations that would suit the Indian conditions better, all of which have been integrated into the Deccan’s product development.

Deccan Auto had also accompanied a delegation from APSRTC to one of the leading transport companies in Beijing, Beijing Bus Transport Company, which owns a fleet of more than 27,000 buses in the city. “We wanted to make sure that the operations team of our future customers were able to see the performance of the buses before we adopt the technology in India”, says Mr. Norhi.

After a comprehensive analysis of the buses with the Indian conditions in mind, the Deccan Auto team zeroed in on three Chinese manufacturers for the technology transfer. “We had a clear choice of European and Chinese Manufacturers and deliberately chose the Chinese as they had the technology and the scale of operations required to support us. The Chinese have mastered the art of bus manufacturing and are able to work on the design changes required in the Indian market. Many Chinese bus manufacturers have been involved in a European alliance in the past which has helped them absorb European technology and processes to a great level in addition to modifying and adopting the technology to suit their requirements. This is what attracted us to the Chinese brands compared to the Europeans ones”, confirms Mr. Balaji.

Focus on niche segments

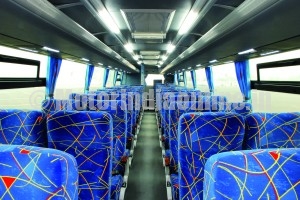

Deccan Auto buses made their debut at the recently held Busworld India show. On display were 8m, 10.5m, 12m and 13.7 buses, all of which are expected to be commercially available by the end of 2013. The buses come with a host of facilities including chemical toilet, luxury seats in 2+1 and 2+2 configurations, individual video screens for each seat with six channel controls, coffee machine, refrigerator compartment, water cooler and covered luggage compartments.

Deccan has established a technical collaboration with Zhong Tong, a Chinese Government-holding company, for the 8m, 12m and 13.7m buses. The five decade old Zhong Tong rolled out 12,000 buses last year and has an annual production capacity of 20,000 buses. Deccan has developed the 10.5m bus by partnering with Yaxing Coach, a 61-year-old Chinese company, also government-held. Yaxing is part of the same group that manufacturers engines under the Wechai brand, which also has gearboxes and axles in its portfolio. While Zhong Tong caters to the luxury segment, Yaxing’s role will be in the mass market volume segment in India. Deccan Auto plans a foray into the city bus segment next year and is also eyeing a potential electric solution later, for which it is working with a subsidiary of SAIC (formerly Shanghai Automotive Industry Corporation) of China.

The 8m semi-integral design bus comes with a rear engine, air-suspension and air-conditioning. The 29-seater luxury coach is mainly targeted at premium routes with low occupancy rate and being smaller in size than the regular buses, has the advantages of better mileage and lower maintenance costs. The Catch, as it is called, is a 2+2 seater version and would cater to the high-end school bus segment and also the highly potential corporate cab segment. The bus is priced at around Rs. 40 lakhs.

The 12m bus is also based on a semi-integral design and comes with a 330 hp rear engine. Deccan is looking at entering the sleeper coach segment with this model and plans to utilize the existing bus body-building resources in the country for building the bodies on the chassis, though fully-built buses 12m buses will also roll-out from the company’s Hyderabad facility. The 12m Navigator costs close to Rs. 1.1 crores.

The 13.7m Navigator is India’s first one and a half deck bus, designed to give a completely new travel experience to passengers. Since the passengers seats are on a higher platform, there is minimal engine noise heard, at the same time, the ride is quite smooth even under poor road conditions. With 59 seats, the model has a central door and a rear toilet, and comes with enormous luggage space below the passenger deck. Despite carrying a price tag of Rs. 1.5 crores, Deccan is confident that the super-luxury bus will be a success, considering the growing demand for luxury and comfort in the Indian market.

Though luxury buses are growing in demand in the Indian market, the volumes are still in the standard chassis front-engine buses. Deccan has introduced the 10.5m model, which comes with a 180 hp front engine, in order to capture a share of the mass market segment. The vehicle comes with options for air-suspension and engine-operated air-conditioning.

The new entrant will work on 50 to 100 CKDs from Zhong Tong and Yaxing to begin with and gradually source components locally in India to cut down costs. It is targeting around 40 per cent localization by the end of the first year and achieve complete localization of relevant components by the third year. However, Deccan is open to sourcing components from outside India as it prefers to prioritise quality over costing. The company will initially focus on the states of Karnataka and Andhra Pradesh and is setting up service workshops in Hyderabad and Bangalore. It is keen on working with large fleet operators in the country as it chalks out plans to expand its network for a pan-India reach over the next few years.

With extensive market study, technologically strong partners and a range of buses which could potentially fill the existing gaps in the Indian bus market, Deccan Auto seems to have got its strategy right. The next few years would be an intriguing phase as we wait to see how the Hyderabad-based entity performs, as it hopes to deliver big in the local market.