Delphi Technologies is ready to deliver the future with electrified solutions for commercial vehicles. The solutions are focused on innovations in electrification and power electronics, two technology sectors where the company believes a fresh approach can bring amongst the most significant and cost-effective benefits to vehicle manufacturers and operators.

“This is a logical step for Delphi Technologies as it brings together three closely aligned areas where we already have considerable expertise. Our electrification technologies for passenger cars are already winning substantial new business and are directly scalable; we have proven capability in state-of-the-art CV engine management and powertrain control technologies; and finally, our long-term relationships with leading CV manufacturers around the world give us a proven understanding of the duty cycles and other specialist requirements of each CV sector” explains Martin Knopf, managing director, electronics & electrification EMEA.

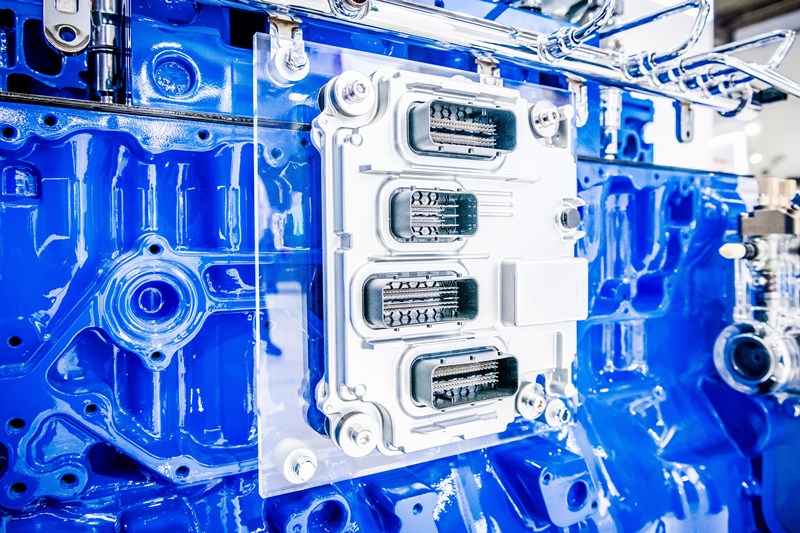

This deep sector expertise has allowed Delphi Technologies to align its capability with electrification strategies of its customers. An example is the new Viper high voltage power switch with superior thermal management and packaging as a key subcomponent inside its inverters. Inverters, which transform direct current from the batteries to alternating current for the e-drive motor are one of the highest-value electrification components and its efficiency has a big impact on vehicle performance.

“Range and charging time are even more critical to CV operators than they are to passenger cars. Electrification has also traditionally not been particularly light or compact, both of which are critical to operators who need to carry paying passengers or cargo, not additional technology. Our Viper differentiated power switch is designed with no wire bonds which greatly improves reliability and thermal management, which is crucial in electric powertrains. It also allows for flexible mechanical packaging options and scalability for our inverter. The net result is that our inverter is 30-40 percent smaller and lighter than the competition, and innovations such as the Delphi Technologies Viper make this possible” says Delphi Technologies commercial vehicle sales director Richard Green.

Revealing more of the company’s technology roadmap, Mr. Green says the global engineering team is already working with CV customers on electrification at up to 800 Volts. “Higher voltages allow smaller, lighter electrification systems, increasing vehicle capacity and allowing faster charging to help keep them working. Further along our technology roadmap we are confident that power electronics based on silicon carbide semiconductors will allow another step-change in efficiency, and again, Delphi Technologies expects to be one of the first to market with a highly-robust system” he says.

Delphi Technologies electrification solutions will be developed and manufactured in every region, with new facilities currently being built in Poland and China. Once operational, the Polish facility, located at Blonie, will manufacture DC-DC converters, inverters and control units.