Donaldson India Filtration Systems Pvt. Ltd., the wholly-owned subsidiary of the Minnesota-based company, a leading worldwide provider of filtration systems and replacement parts, is actively looking to expand its business in the booming transportation segment in the country. Already commanding 70-75 per cent in the off-road vehicle segment, the company is now planning to replicate the success story in the on-road vehicle segment.

Founded in 1915, Donaldson Inc. is a technology-driven company which serves customers in the industrial and engine markets, including dust collection, power generation, specialty filtration, compressed air purification, off-road equipment, industrial compressors, heavy trucks and light vehicles.

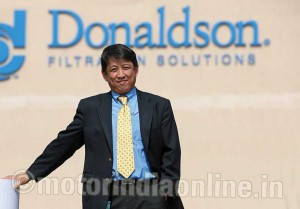

In a one-on-one interaction with MOTORINDIA at its corporate office in Manesar, Terry Lee, Managing Director (South Asia), Donaldson India Filter Systems Pvt. Ltd., stated: “The burgeoning transportation segment has a huge potential for multinational filtermakers like us. Of late, most of the global players have forayed into the country. In addition, the domestic OEMs are also upping their technology ante when it comes to new products. With Donaldson products, we have the best fit for our customers’ future solutions. So the transportation market for Donaldson is very imperative. It’s clearly the market that we want to focus on both in the direct and aftermarket verticals.”

Talking about USP of its product lines which can give it a jumpstart in the on-road vehicle space, Mr. Lee affirmed: “We are quite technologically superior in the CV space, which gives us an edge when it comes to competition. We have been recognized for innovations made in air filter technology and have been spending heavily on research and development activities at our global technical centre. Globally, we have also participated in technological advancements associated with fuel cells. We strive to deliver the best filtration products in the markets we serve, offering superior customer support and a vast network of locations across the country.”

It is a known fact that Donaldson Company Inc. is a vertically integrated filtration company engaged in the production and marketing of products used as a means to improve performance efficiency and air quality. Its products are used by a variety of industry sectors, including commercial/industrial (engines, exhausts, transmissions, vents in private vehicles, hydraulics), aerospace (helicopters, planes), chemical, alternative energy (windmills) and pharmaceuticals. As a multinational company it operates in Belgium, Mexico, China, the UK, Thailand, the US, Russia, Japan, Italy, Germany and France.

Asked to shed some light on the Indian market, he maintained: “It is definitely a developing country. But compared to Greater China, Australia, Japan, South-East China, India is lagging far behind. The country’s GDP grew by only 4-5 per cent. Nonetheless, India is the fourth CV manufacturer in the world, and we are betting big on that. I really hope that under the Modi regime, the economy will get a kickstart. The Asia Pacific belt is contributing for more than 25 per cent of the global operations and there will be an unprecedented growth in the Indian arm in the next few years.”

It may be recalled that Donaldson Inc. entered the Indian market through a joint venture in 1992 and initially focused on the industrial segment. After five years, it took over its local partner’s stake when it came to be known as Donaldson India Filter Systems Pvt. Ltd.

Taking us through the first phase of the company’s operations, Mr. Lee stated: “We initially focused on the gas turbine business which is related to power plants. Thereafter, we diversified into the engine segment. There are a lot of transportation manufacturers (both off- and on-road players) and tractor companies which we wanted to cater to. We expanded capacity of our existing plant by adding new product lines in the automotive segment. So Donaldson has two big business units if we divide it into engine and industrial segments. The engine segment also has the aftermarket vertical along with off-road, transportation, tractors, aerospace, defence, etc. In the industrial segment, we supply the gas turbine and dust collector for most of the industries and also some compressor-related parts for miscellaneous industries.”

Delving a bit deeper in the non-automotive segments, Mr. Lee mentioned: “In the industrial division, we make liquid filters for oil and gas industries, dust collector solutions for pharmaceutical and steel industries, filters for compressor-related products (for various industries) and also dust collectors for the chemical industry. We offer filters that provide gearbox for wind mills. Going forward, we are keen to tap aerospace, aviation and defence applications.”

The filter-making giant has already pumped in a major portion of the investment it had earmarked in 2009. The aforesaid amount has been primarily spent on expanding the existing plant, adding new assembly lines, setting up machinery, extending product lines, etc. The company is now gearing up to spend a similar figure for building greenfield/JIT facilities in the future, specifically for air and liquid filters. Currently, it rolls out two lakh air filters and 30,000-40,000 liquid filters per month from its in-house facility at Manesar.

Mr. Lee, who is a South Korean expatriate being entrusted to ramp up Indian and South Asian operations, concluded saying: “Although there are quite a few hiccups here, like too many regulations, unfavourable tax structure, and lousy logistical channels, I am still upbeat about the growth of India’s economy. We are here for the long haul and aim to be the market leader in the Asia Pacific market in the filtration space by 2021.”

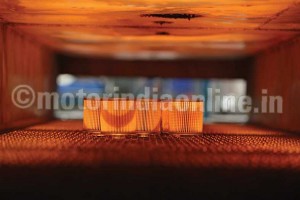

Filtration system to keep diesel fuel cleanHigh-pressure common rail fuel injection systems have spread to more diesel designs as engine manufacturers continue to pursue increasingly stringent emission standards. While they have performed as advertised, these sophisticated systems can be susceptible to damage from contaminants in the fuel. With today’s fuel injection systems operating at injection pressures of up to 30,000 psi and future systems expected to reach as high as 45,000 psi, it is easy to see why even the smallest particles could wreak havoc with precision fuel injection components. To help equipment operators avoid those issues, Donaldson Filtration Solutions has developed a portable bulk diesel filtration product that is designed to remove dirt, water and contaminants from diesel fuel in a single pass. “Donaldson’s customers need two things – a filter system that is easy to install and one that can handle high flow rates”, said Mr. Manish Tripathi, Marketing Manager – South Asia, Donaldson. The Donaldson clean fuel carts are designed to filter diesel fuel to an ISO 4406 cleanliness levels of 14/13/11, which is beyond the requirements of the Worldwide Fuel Charter. The company said diesel fuel filtered to less stringent cleanliness levels won’t always stop the contamination that can cause damage to HPOR fuel injection systems. The cart uses a 24/12 V Piusi Panther electric pump with a flow rate of 21 gpm to pass the fuel through Donaldson’s P568666 particulate filter and a P570248 water element, which is designed to stop all free and emulsified water. The cart includes a clear, 9.84 ft. long 1 in. wide section hose and a 13.12 ft. x 0.75 in. discharge hose. He said: “It’s a lightweight, versatile tool that would be perfect for any construction site. It can be used to pump fuel into equipment or to clean up a tank that has contaminated fuel in it”. Rental companies might want to include the portable filtration product to help ensure the customer is using clean fuel. “No matter how dirty and wet is the fuel coming in, you’re ensured clean, dry fuel coming out the other side. We believe that fuel issues shouldn’t be operational issues as we believe that our customers shouldn’t be slowed down by dirt, fuel chemistry or water,” added Mr. Tripathi. |