Donaldson will present a range of Alternative Power technologies for hydrogen fuel cell and battery electric vehicle applications, plus showcase solutions for alternative fuel-powered internal combustion engines. The company’s products on show at the Hannover exhibition are all designed to help OEMs in their quest to deliver the safe, sustainable transport solutions of tomorrow.

This year’s IAA Transportation exhibition in Hannover, Germany, takes place under the banner of ‘pioneers of transformation’ and Donaldson Company, Inc., will be among those showcasing its future-focused technologies. Donaldson’s legacy of quality and innovation is built on more than a century of experience in solving the industrial sector’s most complex challenges. As hydrogen fuel cells and battery-electric systems become increasingly complex, the company’s experience will be vital in delivering advanced contamination control solutions to maximize their efficiency.

Key highlights of Donaldson’s showcase at IAA Transportation 2024 will include:

- Alternative Power filtration systems

- Innovations in non-diesel fuel filtration technologies aimed at enhancing operational efficiency and longevity

- Venting solutions that support customers in their environmental commitments and compliance with regulations.

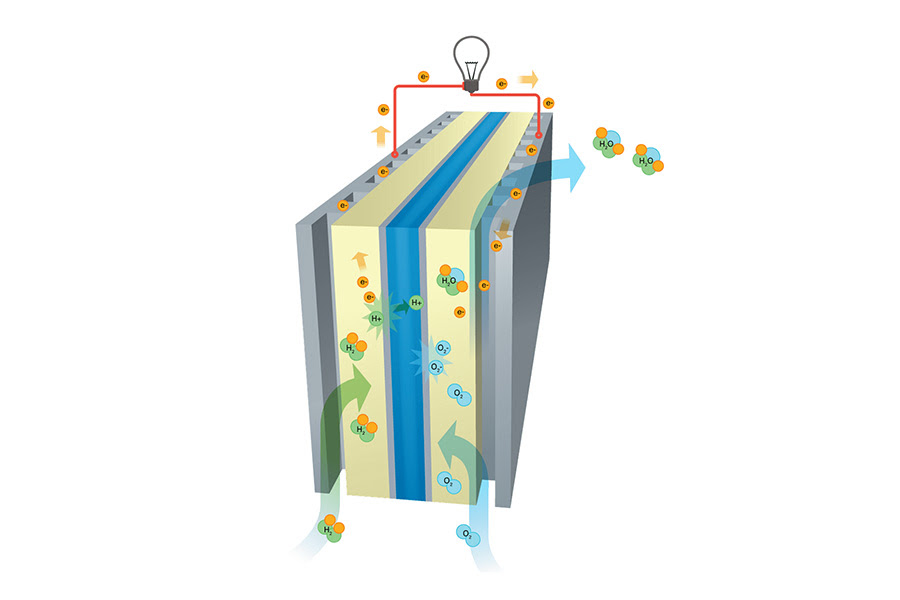

Having worked with fuel cell manufacturers for over 25 years, Donaldson is one of the few suppliers able to tailor precision-engineered ePTFE membrane support options for each specific application. Providing critical structural support to a fuel cell’s proton exchange membrane (PEM), these reduce mechanical stress and breakdowns of the ionomer, which swells and contracts in response to changing humidity levels. By enabling the creation of thinner, more durable and efficient structures, ePTFE skeletons help maintain higher current density and can therefore reduce the number of cells required in a stack.

“The transportation industry is rapidly evolving so it’s vital OEMs have access to the most advanced components and technologies to streamline their delivery of safe, sustainable solutions,” said Keith Bechtum, Vice President of OEM Sales, Donaldson. “Our presence at IAA Transportation 2024 reflects our dedication to delivering superior filtration solutions that not only meet current industry needs but also anticipate future challenges. We are eager to help visitors experience firsthand how Donaldson’s cutting-edge technologies continue to set new benchmarks in reliability, efficiency and durability.”

Keep it clean

Donaldson’s latest fuel filtration technologies will help advance the next generation of transport solutions while helping them maintain high productivity levels to further reduce the sector’s dependence on fossil fuels. For example, hydrogen fuel is an area of huge potential for reduced emissions transport, but it can suffer from contamination from oil, water, other gases and sulphur compounds. So, Donaldson’s high-pressure (<420 bar) and low-pressure (<25 bar) filters will be essential components in helping this segment deliver on its potential.

Similarly, air is essential for fuel cells, but it can often be filled with particulates and chemical contaminants that adversely affect function and lifespan. Donaldson has leveraged its extensive portfolio of proprietary filtration media to develop tailored solutions through its range of cathode air filters. These typically rely on multiple layers – including activated carbon, an acid and base layer, and a dust filter – to screen out sulphur dioxide, nitrogen dioxide and ammonia, while allowing for customization to safeguard against butane, toluene and other unwanted compounds.

Visitors to IAA Transportation will also see a host of other Donaldson technology at the show including its range of humidifiers, water separators and coolant ion exchangers, each of which play a vital role in ensuring the efficiency and productivity of new power technologies. The humidifiers, for example, ensure a high and stable level of humidity in the air supply to maintain fuel cell performance. These work by transferring humidity from the exhaust gas to the inlet air stream prior to entering the fuel cell, providing optimal operating conditions for the ionomer.

The water separators, meanwhile, limit potential fuel cell damage by making sure the intake air filters stay as dry as possible, while certain applications also require the discharge of liquid water from the tailpipe to be controlled. And the coolant ion exchangers help remove other contaminants that can come from within a PEM fuel cell itself, in the form of ions from materials in the bipolar plates, radiators and other coolant circuit components leaching into the coolant. They work by capturing the ions on a special resin, ensuring the coolant remains non-conductive and maintains a low dielectric constant to promote optimal performance by efficiently removing waste heat. A screen is integrated into the same housing to prevent larger particles from blocking the channels in the bipolar plates.

Need to vent?

Manufacturers of automotive battery packs seeking to enhance battery life and reliability can use IAA Transportation to evaluate Donaldson’s latest battery-venting solution, the Dual-Stage Jet which launched earlier this year at The Battery Show in Stuttgart, Germany. This takes EV safety to a new level by offering the industry’s fastest degassing capabilities, at rates of approximately 100 lit/sec @ 100 mbar in an emergency. The new medium-pressure solution features an intelligent poppet and cap design that can be immediately jettisoned to produce a large opening for gas to escape should an emergency occur.

Fuel cells have to operate within a sealed housing to prevent the entry of dirt and moisture, however a membrane vent must be incorporated to allow the enclosure to breathe. One of the most durable solutions is Donaldson’s Tetratex® membrane, and it will be on show at IAA Transportation so visitors can understand how it can integrate directly into the housing to create vent assemblies that meet specific application requirements. Also on show will be the high-pressure Dual-Stage Burst, enabling a pressure relief of 25 lit/sec @ 300 mbar after a series of pins pierce its Tetratex ePTFE membrane.

Donaldson invites attendees, media, and industry professionals to visit Hall 23, Stand A34 throughout September 17-22, and discover how its filtration solutions are driving progress in the commercial vehicle sector.