The best way to efficiently control production processes in the automotive industry is through the use of relevant, up-to-date, and transparent key figures. The new business intelligence application for control technology from Dürr makes this possible. DXQbusiness.intelligence saves information optimized for reading in a separate data warehouse, visualizes it using clear dashboards, and allows the user to create custom reports. This means that manufacturers always have a close eye on the availability, performance, and quality of their plants.

Solutions based on business intelligence (BI) functions provide a fast overview of production, and in this way support decision-making in plants. They do this by collecting important information, preparing it, and displaying it in a clear format. What makes DXQbusiness.intelligence special? The historical production data is collated from different sources, transformed, stored and optimized for reading in the data warehouse so that it can be easily accessed for analyses and reports. Unlike conventional servers which do not store data optimized for reading, the separation of the data warehouse from the customer’s operational system has the big advantage that accessing the data warehouse does not cause any delays in production.

All key data on the screen

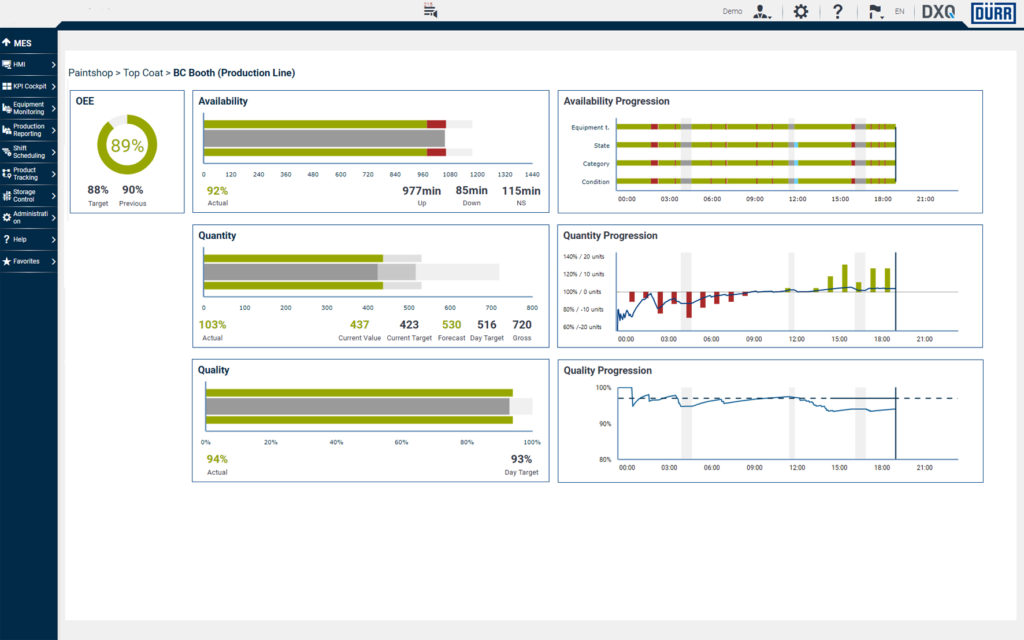

The data warehouse provides structures and tables for long-term orderly data storage across division boundaries. This is because DXQbusiness.intelligence is part of DXQcontrol, which is Dürr’s control technology for controlling an entire plant’s production. The new application from Dürr’s Manufacturing Execution System (MES) displays the production data in a clear, easily understood dashboard. It works in a similar way to the instrument panel in the cockpit of an airplane, which shows the pilot all key data on one screen. Transferred to car production in a plant, the dashboards show the managers mission-critical data to keep production on the right track.

Sound basis for data-driven decisions

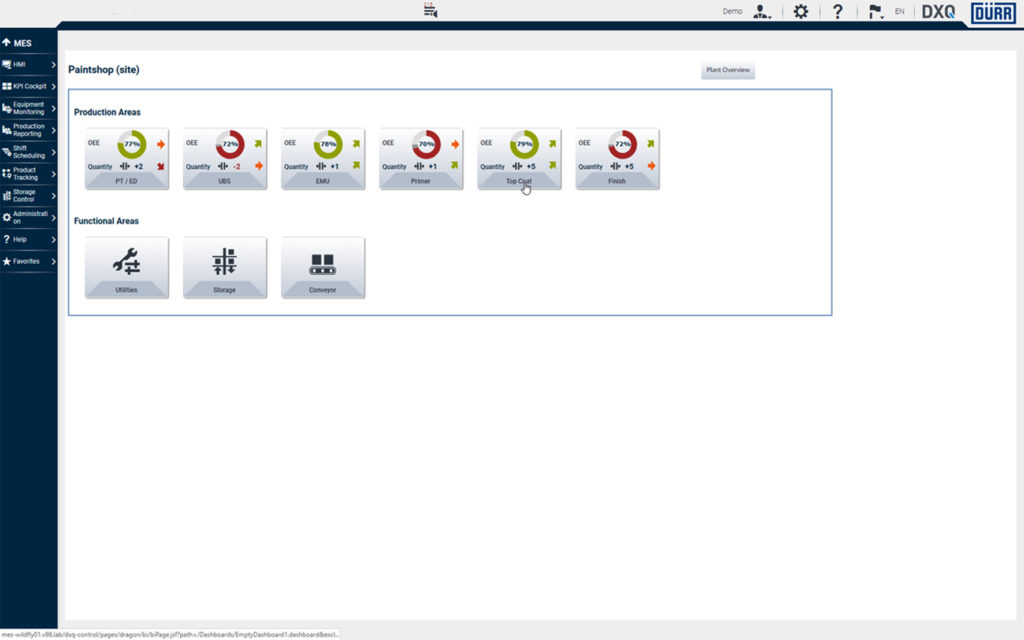

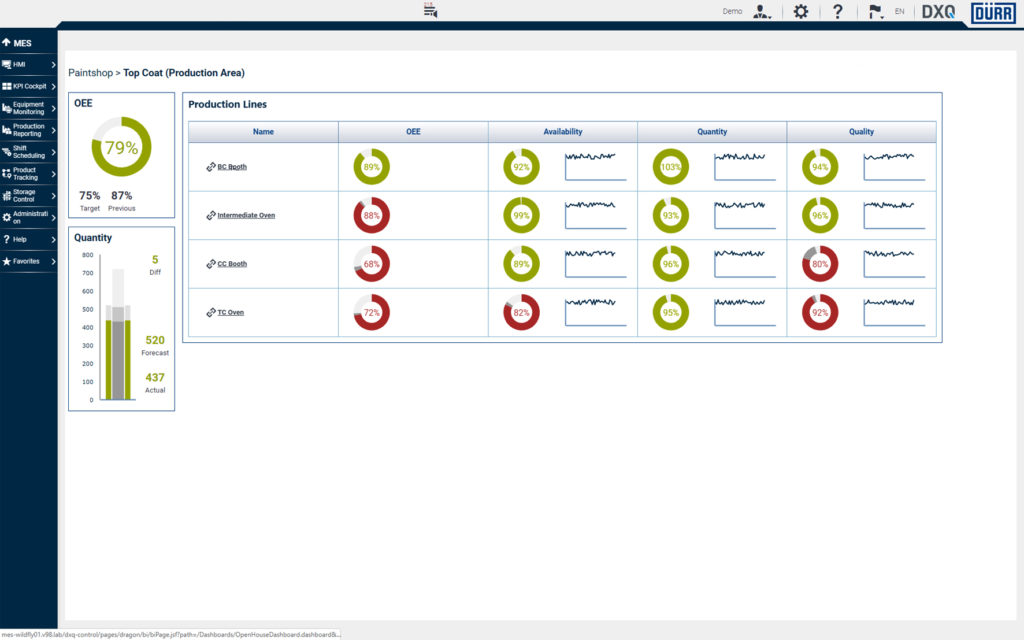

Every decision-making process requires different data. To get the right overview, the user can navigate purposefully with DXQbusiness.intelligence across the entire site, limited to specific production areas such as cathodic electrocoating or focused on individual lines like the cathodic electrocoating dryer. For production, the overall equipment effectiveness (OEE) as well as quality and quantity data is displayed. For individual lines within the production area the temporal progressions of the above-mentioned key figures are also displayed.

Adaptable to individual needs

Users can create reports and arrange them individually according to their priorities and company standards. This gives a solid starting ground for decision-making based on specific production data. Situations that require particular attention can be quickly monitored and tracked using custom reports.