As a global technology leader in power management, Eaton’s portfolio of electrical, hydraulic, and mechanical solutions enables customers and users operate construction equipment more efficiently, safely and reliably sustainability. From road building to demolition, from rock quarries to utilities, Eaton delivers durable products for mini, midi and large excavators that work in the most demanding sites.

From hoses and fittings to pumps, valves to motors, electronic controls and software to electrical and filtration, Eaton products help make customers’ machines more productive and more efficient. Eaton’s experience and systems engineering expertise stand out in the construction and mining industry. Uniquely positioned to offer complete hydraulic and electrical systems, Eaton offers one of the most comprehensive ranges of products and solutions for the excavator platform.

Eaton’s hydraulic systems for excavators have earned a global reputation for durability, reliability and high productivity. Eaton’s experts are committed to supporting customers and designing solutions that deliver efficiency and performance. Its products can be found on today’s best-selling excavators. The company’s complete system approach helps equipment manufactures to optimize machine performance and cut fuel costs. Its open center hydraulic system, including CMJ80, HRCs, JMV and JMF motors, help customers’ excavators to increase productivity significantly.

Eaton’s improved HRC4 joysticks feature robust seals that endure, proven by a three-million cycle lab durability test. The design contributes to easy and precise control and delivers 50% reduction in the potential for internal leakage. The new aluminum housing is 50% lighter than previous cast iron. And, operators will experience greater comfort and handling with 15% lower operating torque.

Manufacturing for competitiveness and stronger quality

Eaton produces thousands of piston pumps and motors every year, with proven experience and performance in various platforms. Its production teams demonstrate its expertise each day delivering quality and improving processes to ensure efficiency in manufacturing. The company’s global team includes experts in hydraulics systems for excavators, design, test, application and field service. Eaton’s Application and Commercial Engineering teams and global network of distributors are dedicated to solving some of the toughest challenges faced by the customers and the end-users.

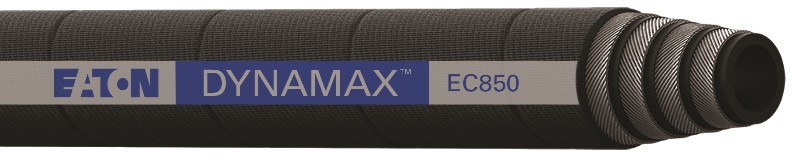

Eaton launches Dynamax EC881 at EXCON 2017

Eaton announced the launch of Dynamax EC881 at EXCON, a high performing two wire braided hose qualified for 1 million impulse cycles. As compared to standard EN857 2SC hoses, which are qualified for 200000 cycles, EC881 exceeds the standard impulse cycle by 5X. EC881’s USP is the impulse cycle rate, which is the key measure of life expectancy and overall quality of a hydraulic hose. It is designed to provide exceptional performance in tough applications. It also provides higher pressure ratings than standard two wire braided hose, superior flexibility (1/3 SAE 100R2 bend radius at 100 deg. C) with Dura tuff cover.

Key Benefits:

- Reduction in weight of braided hose assembly and better hose flexibility

- Extended product life expectancy over standard EN857 Type 2SC hoses

- Allows use in a broader range of hydraulic systems where four spiral hoses may have been required in the past

- Better sealing and leak free performance

- Improved flexibility for easier installation in tight spaces

- Provides additional abrasion resistance, which is a leading cause of hydraulic hose failures

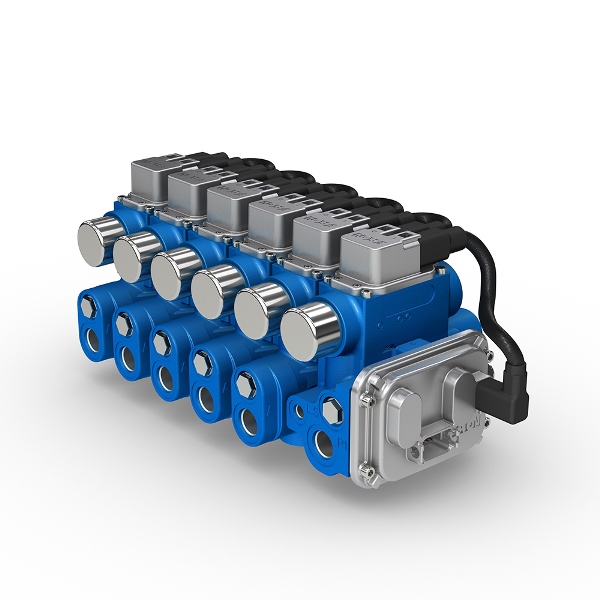

Eaton introduces CMA200

The company also announced the introduction of CMA200, an advanced CAN-Enabled electro-hydraulic sectional mobile valve for the Indian market. CMA200 comes with independent metering that utilizes pressure and position sensors, on board electronics, and advanced software control algorithms. Where conventional mobile valves often compromise on precision or response, the CMA delivers both. The CMA offers high performance with sub-micron hysteresis, closed loop control over the spool position, and repeatable performance. CMA offers customers the next generation in advanced mobile valves with unlimited possibilities to differentiate your machine capabilities.

Key Benefits of this advanced mobile valve include:

- Precise control maintained for all load conditions

- Reduction in metering losses / energy management

- High valve responsiveness

- Flow Sharing – Pre and Post Comp Capabilities

- Flexibility in configuration / easily change parameters

- Command factory-calibrated flow or pressure from either work port

- Easier communication with the valve

- Reduced load on the Vehicle CAN bus

- Advanced Diagnostics for improved reliability and productivity

- Hose Burst Detection

- Limp mode

- Diagnostics on the inlet, tank, load sense, work port pressures, spool position, consumed flow, and oil temperature.

- Platform can support future software development for future product development.

- Reliable performance across a broad temperature range

Eaton’s CMA valve drives dynamic machine control

Whether snowboarding, downhill, or cross country skiing, resorts around the world count on well groomed slopes to keep the conditions safe and their customers happy. With snow groomers named HUSKY, BISON X and LEITWOLF (to name just three) PRINOTH delivers on performance with innovative technology, efficiency and a strong design. Those core drivers power PRINOTH employees worldwide to develop the most innovative and smart snow groomers, and for good reason. The crews piloting the vehicles work in extreme conditions. Snow. Ice. Steep slopes. And, they do it all at night. They need to rely on state of the art equipment.

That’s why PRINOTH relies on resource-efficient use of the snow groomers and provides ski resorts with the knowledge necessary to improve performance and reduce operating costs. Along, with the equipment, they provide specialized training for snow groomer drivers. The combination helps ski resorts achieve the best result – the perfect run.

PRINOTH made advances in engine management and in the interface between human and machine. But traditional hydraulic approaches applied to biggest machines, with more than 500 horse power – making the machine extremely fast on the slopes, were not allowing enough response time. Also, with traditional systems, the hydraulic options to achieve good flow control was an overuse of orifice restrictors which could generate noise in some conditions.

Eaton was challenged to provide innovative components to help PRINOTH make smarter, more dynamic machines.

Dynamic Machine Control means quieter, quicker and more efficient operation. Eaton provided a CMA valve digitally tuned with the Pro-FX Technology platform to help PRINOTH improve response times on the machines. The CMA valve is an advanced mobile valve with independent metering, which offers nearly endless possibilities to differentiate machine capabilities. The CAN-enabled electrohydraulic mobile valve also features on-board electronics and sophisticated software algorithms, providing PRINOTH with market-leading intelligence, capabilities, dynamics and control.

The CMA valve has helped produce remarkable changes in response times. Where older systems had a typical response time of 1.1 s, systems making use of the CMA valve produce response times of 0.15 s. For the operator adjusting the blades on a snow groomer, this appears as a nearly instant response, which allows for precise control on the slopes no matter the conditions.

Since Eaton CMA valve functions as an embedded system, it communicates on the CAN bus and does not require dedicated wiring. An embedded system simplifies both the manufacturing and the subsequent servicing. With the LEITWOLF model in particular, PRINOTH used CMA valve technology to make dramatic leaps in improving serviceability.

With its competence in manufacturing tracked vehicles, PRINOTH also develops tracked utility vehicles for off-road use in remote areas as well as tracked carriers with mulching attachments for the sustainable management of vegetation areas. Dynamic machine control is the driving force behind smarter machines, including snow groomers. Several innovations become available when using Eaton products that provide for DMC.