In an exclusive interview with Ravuri Ramu, Director, Sri Raja Rajeshwari Constructions India (P) Ltd., N. Balasubramanian and Rajesh Rajgor find out how the company is scaling newer heights from irrigation, railways to road projects and buying efficient vehicles, including Eicher tippers that makes them one of the most successful players in the segment

Sri Raja Rajeswari Constructions (India) Pvt. Ltd. (SRRC) needs no introduction in the field of civil engineering and infrastructure construction in India. The company is synonymous with irrigation projects, especially in the states of Andhra Pradesh and Telangana. One of the projects that bolstered SRRC’s name across India was the Mid Manair Dam (MMD), also known as the Sri Raja Rajeshwara Reservoir completed in the year 2018. Elaborates Ravuri Muthaiah, Chairman & Managing Director and Ravuri Ramu, Director of SRRC “With a 25.875 TMC feet capacity and 25 radial gates, the Mid Manair Dam is considered as the heart of the Kaleshwaram project and gave us applause and recognition from across India.”

“Similarly, our participation as a subcontractor in the Kaleshwaram Lift Irrigation Scheme for the mammoth Mallanna Sagar reservoir, inaugurated by Chief Minister K Chandrashekhar Rao and hailed as India’s biggest offshore reservoir with a storage capacity of 50 TMC feet, boosted our credibility. Over the past 35 years we have undertaken several such projects across the length and breadth of India making us a pan-India player.” SRRC that transitioned into a private limited company in 2014 has also been diversifying into railways and road projects ever since. The company was founded by Chairman and Managing Director Sri Ravuri Muthaiah.

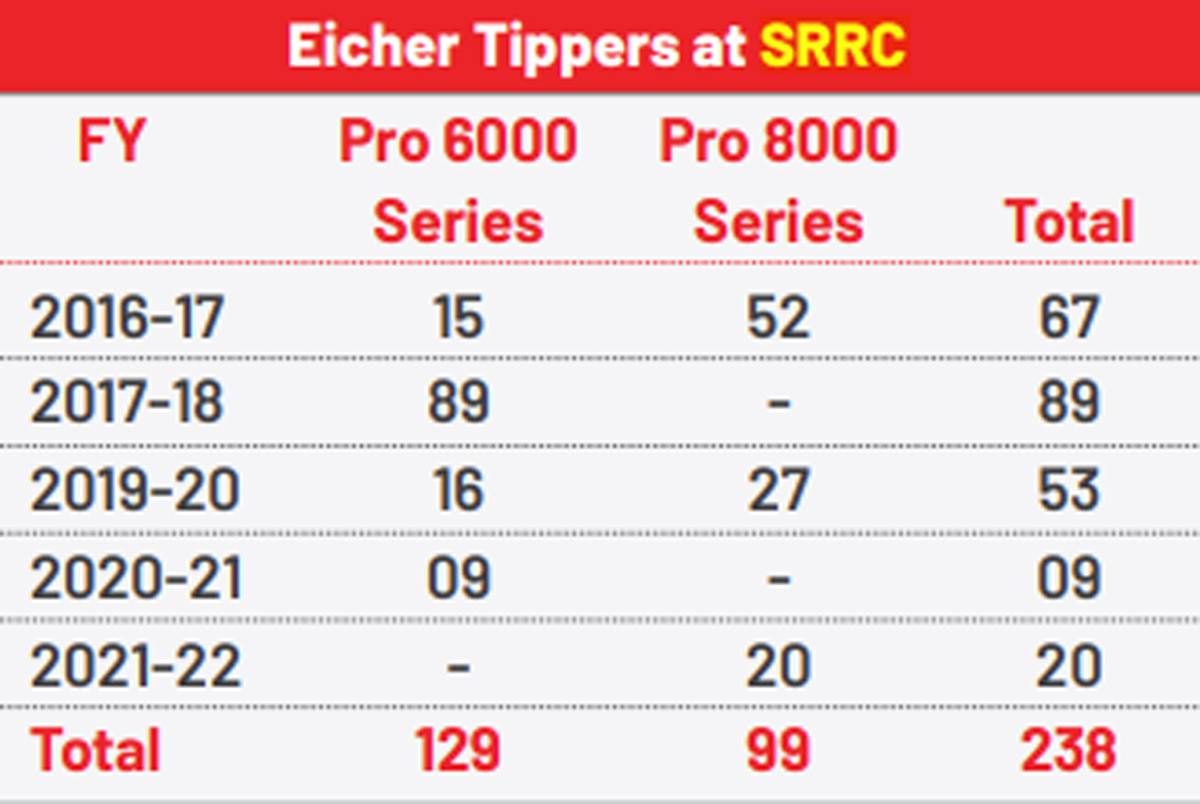

He signed a partnership deed with his elder son Sri Ravuri Ramu in 2007, bringing him into the business to diversify into new projects and take on demanding projects. The partnership firm was transformed to a private limited company in 2014. Since then the company has been investing in a lot of machineries, including excavators, tippers, backhoe loaders, graders, soil compactors, etc., to get the projects completed on time. At present the company has over 240 Eicher tippers, 120+ Excavators, 25 compactors, dozers, graders, tippers, backhoe loaders, etc.

Says Ravuri: “We have a total of 350 tippers that help us take projects across the country from Kashmir to Kanyakumari. We look for ruggedness, fuel efficiency and safety and comfort of the drivers (operators) while selecting the vehicles. Our vehicles need to operate at tough mining sites and rugged road conditions for 18-20 hours and therefore should be able to withstand the challenging duty hours daily as well as provide driver comfort.” Such landscapes but naturally call for tough vehicles which can also be easily maintained and repaired, if necessary, by keeping the downtime at a minimum.

The Eicher Association

SRRC, for whom 70% of work comes from irrigation projects, 20% from railways and 10% from road and other construction projects, owns a total of 240 Eicher tippers as of today. “Our partnership with Eicher dates back to 2015-16 when it introduced the Pro 6000 and Pro 8000 series. We continued buying Eicher vehicles as our projects increased mainly because of the results their tippers were giving us on the sites. Even after 20,000-25,000 km of use the vehicles were performing to their optimum level. The drivers were happy with the comfort, ergonomics and the overall fuel efficiency was 10-15% better than that of the competition,” Ravuri says.

One of the reasons SRRC continued their purchases of Eicher vehicles was the latter’s higher horsepower offering that enabled the company to carry more load even on steep roads. It is also a no brainer that a company of the stature of SRRC puts immense emphasis on service and maintenance. The company is mighty pleased with the service deployed by Eicher. “We cannot stop our operations due to service issues as the nature of our business is that the vehicles do get abused a lot. There are times when the vehicles run round the clock for close to 22 hours. Eicher’s on-site service setup with availability of fast-moving spareparts gives us immense confidence to run Eicher vehicles for hours,” Ravuri says.

“Over the last couple of years their support system has been top-notch and beats the industry standards,” he adds. It is phenomenal that Eicher has not only taken care of the essential service factor, but also made sure that the vehicle uptime is close to 24 hours, requiring minimum service support. As much as the vehicles that work on beast mode, it is the drivers who run these vehicles. They are the essential cog of the wheel in the entire turnaround time. SRRC also hails the superlative efforts by Eicher to provide best driver training to the person hired by the company.

“We have nearly 800 drivers considering we have 350 trucks and each truck requires at least two personnel throughout the day. A few drivers on spare never hurt as there might emerge requirements on site. Whenever we have a new vehicle the master driver provided by Eicher assists our drivers by visiting the site and showing them the proven manoeuvring and ignition techniques that not only make drivers efficient but also improves fuel efficiency and turnaround time. They also conduct periodic training programmes for our existing and new recruits from time to time,” Ravuri informs.

Growing in the Golden Decade

Our interviews with many constructions and infrastructure major reveals that since 2014 the rapid decision-making and investments in infrastructure development projects by the central and state governments have led to stupendous growth in the segment. Echoing similar sentiments, Ravuri adds: “Ever since the Narendra Modi-led government has come to power there have been several projects in roads, railways, airports, ports, smart cities and Irrigation projects by various state governments such as dams, canals, earthen dams, tunnels, lift irrigation works where we either have been a direct contractor or a sub-contractor. Which is similar to the years of growth China saw from 2000 to 2010.”

We expect this growth momentum to continue and will passionately participate in major river-linking projects as well as connected road corridors floated by various states and the NHAI,” he adds. SRRC that generates huge employment with its infrastructure projects for many daily wage workers today employs nearly 2,000 people. This massive number is testimony of the company’s faith in work that will be opened up and come up to them due to their capabilities.

A look at the company’s ongoing project speaks volume of their pan-India presence such as major irrigation projects in Telanagana & Orissa, Railway projects in Maharastra and Madhya Pradesh, Road projects and smart city projects in Maharastra and Telanagana. SRRC is gearing up for their next phase of growth. “At present, we have projects going on in Maharashtra, M.P., Orissa, Telanagana are confident that our reputation and credibility will help us gain more work and reach a four-figure turnover of Rs 1,000 crore from the current turnover of Rs 600 crore”, Ravuri states.

The Union Budget 2022-23 presented by Finance Minister Nirmala Sitaraman has emphasised on ‘PM Gati Shakti’ which will further boost the infrastructure segment. Ravuri opines: “PM Gati Shakti is powered by seven engines: roads, railways, airports, ports, mass transportation, waterways and logistics infrastructure with support from energy transmission, IT communication, bulk water and sewerage, social infrastructure, clean energy and public-private partnerships (PPP). This will certainly be beneficial to us and our medium to long term targets of growth.” And given the emphasis by the company on equipping itself with the best of technology, it is all set to touch the pinnacle of success.