The ElringKlinger Group is a powerful and reliable partner to the automotive industry. Be it car or commercial vehicle, be it optimized combustion engine, hybrid technology, or electric motor – they offer innovative solutions for all types of drive systems in passenger cars and commercial vehicles. In doing so, the company is making a committed contribution to sustainable mobility.

The group’s lightweight solutions help to reduce the overall weight of vehicles and as a result, vehicles powered by diesel or gasoline engines consume less fuel and emit less CO2, while electric trucks and cars benefit from an extended range.

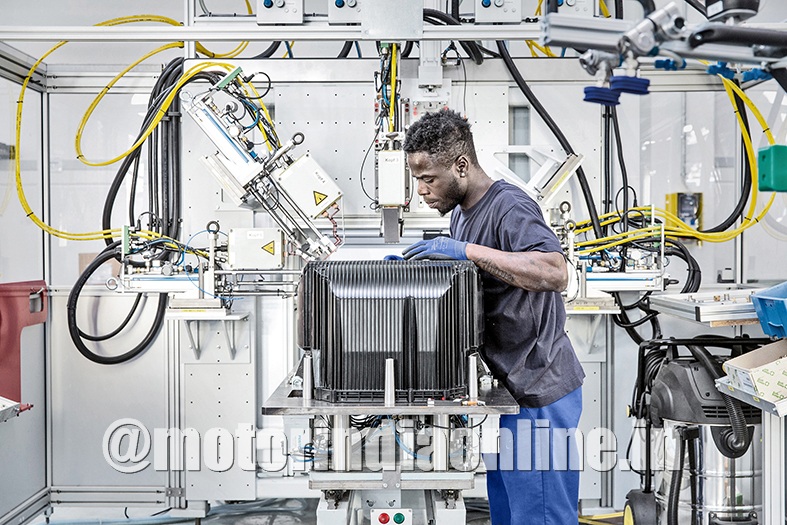

Developing cutting-edge battery and fuel cell technology as well as electric drive units, the company is amongst the frontrunners when it comes to positioning themselves as a specialist in the field of e-mobility.

“The automotive industry as a whole is facing tremendous challenges in the commercial vehicle market. The aim must be to strike a balance between the old world and the new world. Our company is already on the right track and we are delighted to be able to present our wide-ranging solutions for commercial vehicles,” says Dr. Stefan Wolf, CEO of ElringKlinger AG.

MOTORINDIA was amazed to see the number of lightweight solutions that were part of the concept truck presented by ElringKlinger. The solutions included a cross car beam that carries the dashboard, steering column, heating and ventilation modules, airbags, glove compartment, center console, and other features; it ensures that all components are securely connected to the vehicle body. Even in its standard design, a newly developed seat structure incorporates brackets for positioning motors, airbags, the lumbar support, head rest, spring element, enhancement options for lateral support and many other functional features. In addition to offering significant weight-saving potential and the integration of additional functions, the seat structure also meets automotive crash standards.

Mr. Daniel Volles, Global Business Development Manager, ElringKlinger AG, said: “We have three highlights besides the lightweight solutions, one is the fuel cell stack, second is the complete battery system and third is the electric drive unit that we are presenting here. We have all the technology in house to develop and produce those products in mass production in these segments.”

When asked about the offerings for India, he said: “We already have a production plant in India for products like cylinder head gaskets, and supply to local manufacturers. We are coming from a component supplier but moving to a system supplier with highest functionality integration of those parts. For example, ElringKlinger can produce many components inhouse like cell contacting systems, battery module pressure equalizing elements, lightweight plastic components, etc., which are all part of the battery system.”

The company also showed its potential for the efficient manufacture of fuel cell products in large quantities. They showed two PEM (Proton Exchange Membrane) fuel cell stacks with 260 cells (59 kW electric) which can be integrated in fuel cell systems. These fuel cell systems can also be integrated together with a battery to build up a fuel cell/battery hybrid system or as a range extender into a vehicle. The stacks are already used in different applications like forklift trucks, busses and passenger cars in different power outputs.

Another highlight was the energy storage system for mobile applications in the plug-in hybrid (PHEV) segment. The battery system is made up of battery modules consisting of prismatic lithium-ion cells and stores around 40 kWh of electrical energy at a nominal voltage of 400 V. The battery housing can be adapted to the installation footprint. Integrated cooling of the battery modules ensures best-in-class performance.

Additionally, bringing together the engineering skills of hofer powertrain – a specialist in the field of electric drive technology – and its own long-standing expertise within the area of battery technology and fuel cells, ElringKlinger has further cemented its systems competency for pioneering drive technologies. They include a compact axially parallel electric drive unit (EDU) that can be integrated into various vehicle platforms.

Power is transmitted to the half-shaft via a two-stage spur gear and a differential. While hofer powertrain applies its expertise to development and system design, ElringKlinger concentrates on serial production.