Basic HTML Version

MOTORINDIA

l August 2012

123

WABCO is known for its efforts

in research and new product devel-

opment. The company’s R&D head-

quarters is located in Hannover, with

two additional centres, one each in

Chennai and Poland. It is planning

to set up two more R&D centres,

one each in China and the US. It has

a strong R&D set-up in India with

around 150 R&D engineers work-

ing in its mother plant, apart from

another 150 engineers who operate

from the company’s software devel-

opment centre, also located in Chen-

nai. The Indian R&D centre is be-

ing further strengthened to function

as an extended arm of the German

R&D department and will cater to

the company’s global plans as well.

World-class test track

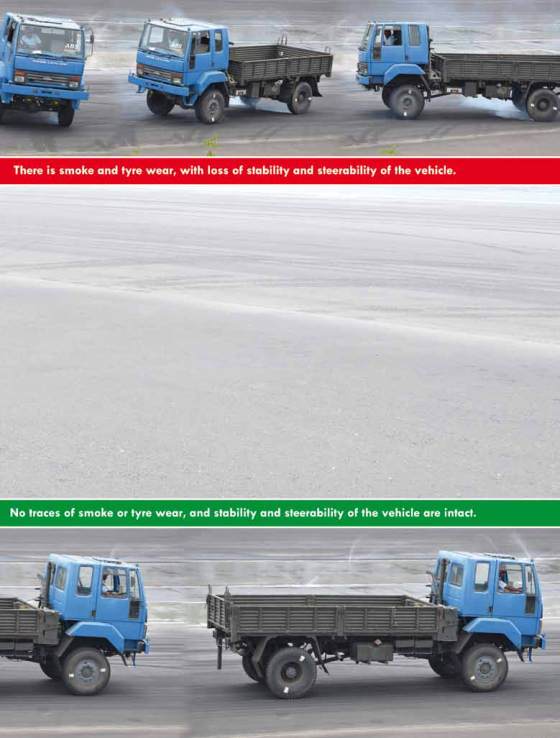

WABCO INDIA’s focus is on

safety, for which the company has

setup a 200-acre test track in Chen-

nai. The facility was established with

a vision of bringing ABS into the

country and it has certainly played a

big role in instituting the technology

in the Indian market. The test track

is the only such facility in the coun-

try and is used by testing agencies

such as ARAI and CIRT for certifi-

cation and homologation of vehicles

for safety.

Says Mr. Kaniappan: “The test

track can simulate roads of different

friction levels based on the require-

ment during product development.

At WABCO INDIA, we design the

brake system indigenously, develop,

produce and validate it and finally

demonstrate it to our customers.”

The test track includes a 1.5 km

straight track with different surfaces

of varying friction, simulating dif-

ferent road conditions for testing.

The dry asphalt surface has a fric-

tion of 0.8 u while the wet asphalt

surface has a friction of 0.5 to 0.6 u.

There is a blue basalt surface which

has a friction of less than or equal

to 0.3 u, to simulate oil patches

and slurry on roads and also a wet

ceramic surface with 0.1 u friction

component zone

“We have around 40 engineers, with

over 10 years’ experience in the field

of ABS, who have been involved in the

development of the product and also

the test track. Without the test track,

certification for vehicle safety would

not have been possible in the country.”

– Mr. Kaniappan