Basic HTML Version

MOTORINDIA

l

August 2012

137

provement in fuel efficiency for the

next generation of heavy duty trans-

missions.”

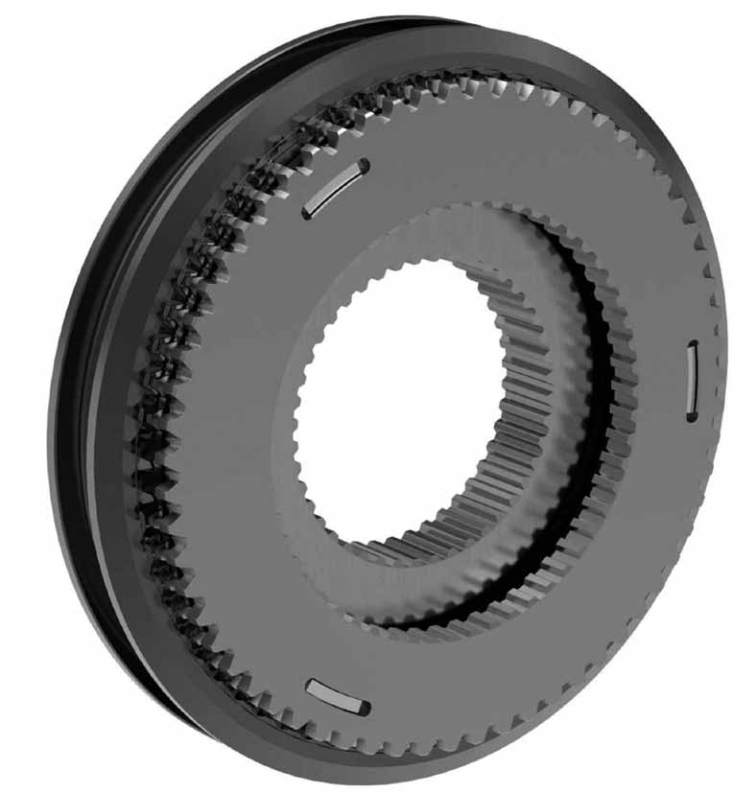

The new synchronizers are con-

figured in single and double cone

arrangements, each with the same

external geometry to allow great

flexibility in transmission design.

In all, four different synchro-

nizer specifications are used on

the 14-speed transmission and

three on the 9-speed. The syn-

chronizers have exceptionally

high torque capacity – up to

18000Nm in the first applica-

tions – and use molybdenum-

coated steel cones for high du-

rability with optimum friction.

Future developments include the

potential for carbon coating.

By increasing the speed of a manu-

al shift, Oerlikon Graziano has been

able to reduce the torque interrup-

tion, keeping the engine at optimum

efficiency for longer and reducing

engine transients to save fuel.

Whichever gear is selected, large

differences in rotating speed can

exist across the other synchroniz-

ers. With a conventional design

this leads to significant drag losses

which impair efficiency, but the new

synchronizers greatly reduce this ef-

fect to further improve fuel econo-

my.

The new synchronizers improve

the shift process during three distinct

phases. Prior to synchronization, the

integrated activation system pro-

vides optimized load characteristics

to give improved consistency and

outstanding durability, compared to

a standard design.

The second phase, synchroniza-

tion, has been shortened by the use

of multi-cone technology, best-in-

class friction materials and the op-

timization of geometries and tribo-

logical properties.

The third phase, from synchro-

nization to engagement, has been

improved by incorporating new in-

ternal features allowing smoother

travel of the sliding sleeve, avoiding

blocking problems and providing a

more friendly engagement feel to

the driver.

“Our priority is to develop trans-

mission technologies that allow our

customers to introduce more capable

and competitive vehicles, whether

for cars, trucks or off-road applica-

tions. The new synchronizers will

support the next generation of truck

transmissions with reduced fuel

consumption and improved driver

convenience”, added Serra.

w

component zone

A key feature of the new technology

is the activation system which is inte-

grated into the synchronizer and opti-

mized for smooth engagement. Appli-

cations are usually manual shift with

air assistance, so any shift problems

are immediately obvious to the driver.

The new system ensures a fast, smooth

and reliable shift under all conditions,

making it an attractive alternative to

a powershift system because it pack-

ages into a much smaller space.