Basic HTML Version

96

MOTORINDIA

l

August 2012

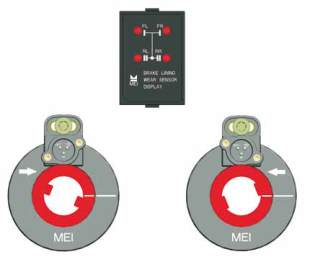

slack adjuster, this kind of wear indicator becomes nec-

essary to warn the driver / operator to replace the lining

in time. Hence wear sensor becomes an in-built safety

devise in the brake sub system in a vehicle.

Similarly, clutch booster was developed as an import

substitution and has been accepted well in the market.

We have developed 70 dia and 90 dia variants, and two

more variants, viz., 76 and 102 dia, are in advanced

stage of development. Here again I would like to men-

tion that these products were indigenously developed,

meeting all customer requirements / validation.

MI: What is the likely contribution of your new

products towards your overall sales five years down

the line?

EKP:

With regard to auto slack adjusters, our current

share is 65% plus in the CV industry, and we are a single

vendor to most of the OEMs and the preferred source

with regard to Tata Motors and Ashok Leyland. Consid-

ering our long range plan with products under develop-

ment, five years down the line, the contribution from

slack adjusters will be in the region of 40% of our total

business and the rest from other products.

As a part of backward integration, we are setting up

our own green field SG Iron foundry near Chennai. This

will cater to our in-house requirement of castings and

the spare capacity will be utilized to cater to the require-

ments of other customers. Our foundry will be an inde-

pendent profit centre.

MI: You had mentioned that MEI has three inde-

pendent manufacturing facilities. Can you explain

more in detail about the infrastructures available in

all these units?

EKP:

We have three units in Chennai, located at Am-

battur, Maraimalai Nagar and Mahindra World City.

The Mahindra World City unit started in 2007 is

coming under the special economy zone and it is fully

dedicated for our export business which at present con-

stitutes 30% of our top line. Ambattur is our mother

plant which was started four decades ago, and the

Maraimalai Nagar unit which was commissioned in

1992 is now undergoing modernization, with auto-

mated assembly lines. All our manufacturing units

have independent machining centers and metallurgical

laboratories.

MI: Nowadays the expectation of OEMs is af-

termarket parts and service support. How are you

placed to tackle this?

EKP:

Yes. We consider aftermarket parts sale and

service support is an integral part of our business proc-

ess, and we are well equipped to tackle this. In our mar-

keting team we have professionals with rich experience

at senior levels supported by a number of field engineers

posted at all strategic locations throughout the country.

We have 22 field engineers to take care of the require-

ments of our end customers in the field, and for spare

parts support we have 70 distribution outlets, again

spread all along the length and breadth of the country.

We are also in the process of opening service outlets

in select locations and have been continuously impart-

ing training to all our end users at all levels. We are also

paying individual attention to State transport corpora-

tions.

MI: As a fast growing and emerging player in the

auto component industry, how do you foresee the fu-

ture of the Indian commercial vehicle industry?

EKP:

Though there is a negative sentiment prevailing

in the industry today, because of the current slowdown,

one thing all of us have to accept is that our fundamen-

tals are very strong. I am hoping that the Government

will take corrective steps to revive the auto sector. I can

only say the current situation appears to be a structural

one and not cyclical. I am hoping for a recovery by early

October.

w

Brake lining wear sensor with display unit

component zone