Basic HTML Version

MOTORINDIA

l

September 2012

123

plier and OEM has to register their

company in order to report their

IMDS sheets. Once registered, sup-

pliers will be able to submit the

IMDS data sheet to their customers

with the complete part, material, ba-

sic substance details and recyclate

information.

Close to 90,000 suppliers are now

registered in IMDS, with 170,000+

active users. Started with 7 OEM

participation in IMDS in 2000, cur-

rently 55+ auto companies partici-

pate as OEMs in IMDS. Almost 99

per cent of OEMs and auto supply

chain use the IMDS database as a

tool to the meet ELV requirements.

It requires all the materials used in

the vehicle to categorize into seven

material families as per ISO 22628

– metals, polymers, excluding elas-

tomers, elastomers, glass, fluids,

modified organic natural materials

(MONM), and others (components,

materials where a detailed break-

down cannot be established).

2015 type approval target – recy-

clability >85 per cent and recover-

ability >95 per cent.

APA Engineering, a Chennai-

based engineering and sourcing

company, has a very strong team to

support the automotive OEMs and

supply chain to meet the ELV direc-

tive requirements for the automo-

tive industry, especially by giving

end-to-end IMDS compliance sup-

port. Recently APA won two ma-

jor orders from leading global auto

MNCs.

The recent happenings in India

towards ELV directive for vehicles

are NATRiP establishing the Re-

cycle Demo Center in Chennai and

a few automotive industry bodies

working towards framing the ELV

directive. The purpose of the Demo

Center is research in ELV recycle in

India. Indian OEMs have provided

old vehicles for the center.

Maruti has already taken an ini-

tiative to make its vehicles ELV-

compliant and launched a few ELV-

compliant cars already in the market.

There is every likelihood of a sim-

ilar ELV being introduced in India

soon.

w

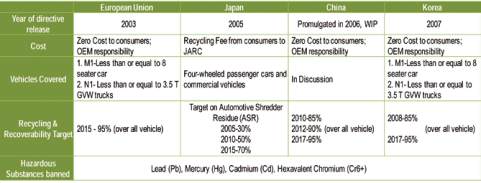

ELV global scenario

The ELV directive has two major re-

quirements – improving the recy-

clability of the vehicle parts and

minimizing the use of hazardous sub-

stances such as Pb, Cd, Hg and Cr6+.

technology