Bags ACMA Gold Trophy for Excellence in Quality and Productivity

Emitec GmbH is a joint venture between Continental AG and GKN Automotive and is the world leader in the design and manufacture of metallic substrate for automotive exhaust gas emission control catalysts, including diesel particulate filter and SCR system for on-road and off-road engine application. The company has long-standing partnership with passenger car, commercial vehicle and motorcycle manufacturers, with its strong presence also in the agricultural, construction machinery, shipping and diesel locomotive industries.

Headquartered near Cologne in Germany, Emitec GmbH currently has manufacturing locations at Lohmar and Eisenach (Germany), Fountain Inn (USA), Pune (India), and at Faulquemont (France), in addition to customer support and application engineering offices at all major automotive locations across the globe with development centers in Germany, France and Denmark. The company owns over 2,500 patents worldwide, reflecting its technical expertise and innovative capabilities.

Emitec India is a 100 per cent subsidiary of Emitec GmbH with the Indian operations kick-started through the setting up of its Application Engineering office in 1996. Emitec India is accredited for ISO/TS 16949, BS-OHSAS 18001 and ISO 14001, Quality and Environment systems. While R&D activities happen from Emitec’s Technology Centre in Germany, it has a strong application engineering team in Pune to serve the specific requirements of its customers.

The company’s manufacturing plant in Pune was founded in June 2005 with production having commenced in 2006. The facility was set up with an initial capacity of five million units which was subsequently hiked to 18 million units annually.

The manufacturing unit has substantially upgraded its technology in the past seven years to cover a wide range of application segments, including two-wheelers and three-wheelers, commanding a 65-70 per cent market share in these segments in the domestic market, in addition to its supplies to LCVs, commercial vehicles and off-highway vehicles. The company caters to the requirements of automotive giants such as Tata Motors and M&M, apart from many others in the country, and clocked a turnover of around Rs. 200 crores in FY13, maintaining a strong annual growth rate of 30 per cent over the last five years.

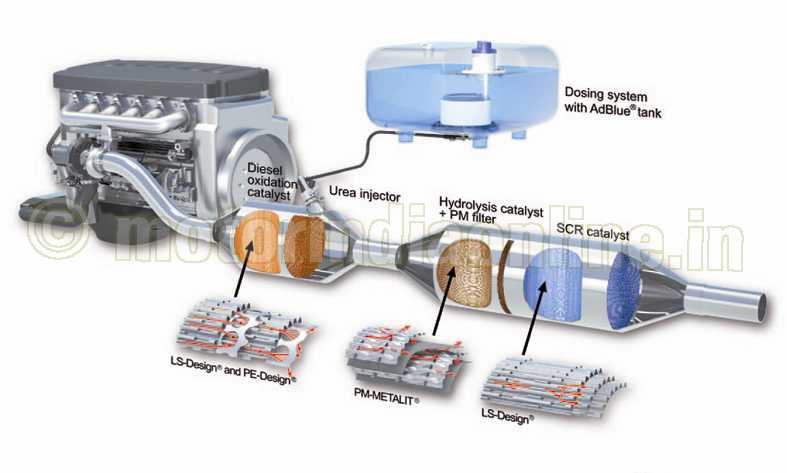

With the acquisition of Grundfos NoNOx division globally towards the end of 2010, Emitec expanded its product and system range in the field of selective catalytic reduction (SCR) technology. Emitec’s NoNOx division designs, develops and manufactures urea dosing units that reduce nitrogen oxide in the emissions of combustion engines. The extremely compact Gen III dosing system developed by Emitec will be offered for passenger cars and light commercial vehicles, while its SCR systems cater to the commercial vehicle and off-road vehicle sectors. With new expertise arising out of the acquisition, Emitec has developed a range of urea dosing pumps, especially for the Asian market, including India.

The ACMA Award

This year Emitec India has received the ACMA Gold Trophy in the category of ‘Excellence in Quality and Productivity’ based on criteria such as work environment and employee involvement, customer assessment and feedback, quality, productivity and cost performance. The company has bagged the award in its very first of participation.

Says Mr. Chistopher Dias, Managing Director, Emitec Emission Control Technologies India Pvt. Ltd.: “The year 2013 has been very significant for us. For the very first time Emitec had applied for the ACMA Award for Business Excellence this year, and we are proud to say that we are one among many companies to receive the award for our excellence in quality and productivity.”

Earlier this year, Emitec India’s Pune plant was chosen as the Best Emitec Plant globally, in recognition of its best practices and impeccable focus on quality.

The company feels that winning the ACMA Award is an integrated effort towards the fulfilment of its vision which is to support the growth in green mobility by providing customers with innovative and cost-effective emission control products and solutions and to deliver increase in satisfaction and value to our customers, employees and all stakeholders’.

Emitec India has commenced the journey to achieve the vision through various short-term and long-term strategic initiatives for continual improvement in quality, productivity, cost, delivery and people development with focus on robust processes with well-defined key measurement indicators and process indicators in place, in line with the company vision.

In order to further strengthen its strategic initiatives, Emitec India has implemented various lean manufacturing principles, including 5S, TPM and Poka-Yoke, set up time reduction, single piece flow, team base work system and effective problem solving tools and adopted the Six Sigma methodology for critical problem resolutions. Individual development is achieved through specialised training modules designed to strengthen the employee skills with various inbound and outbound training programs conducted for strong, efficient and visionary leadership.

Emitec considers its workforce as one of its most important assets and caters to all their requirements through training on health, environment and safety and also calls for employee grievances forums, apart from the technical sessions.

“At Emitec, we spend a lot of time and energy in training people, from both a technical and a cultural viewpoint. We focus on improving ourselves on a daily basis which yields excellent results”, adds Mr. Dias.