“Engineering Advantage and Sector Knowledge are the key to Norgren India’s plans for Commercial Vehicle pneumatic systems”

– Kuldeep Bhan, Managing Director, IMI Norgren Herion Pvt. Ltd.

Motion and fluid control technologies play an integral part in product optimization and efficiency enhancement in vehicles. Norgren, a  world leading supplier of high performance pneumatic motion and fluid control solutions, has been an established player in the field for nearly nine decades. The company has been delivering ‘engineering advantage’ to its customers worldwide which it has also brought to the Indian market. Mr. Kuldeep Bhan, Managing Director, IMI Norgren Herion Pvt. Ltd. responds to questions about his company’s presence in India, the progress thus far, plans for the future and more.

world leading supplier of high performance pneumatic motion and fluid control solutions, has been an established player in the field for nearly nine decades. The company has been delivering ‘engineering advantage’ to its customers worldwide which it has also brought to the Indian market. Mr. Kuldeep Bhan, Managing Director, IMI Norgren Herion Pvt. Ltd. responds to questions about his company’s presence in India, the progress thus far, plans for the future and more.

Excerpts:

Having invented the world’s first lubrication system nearly a century ago, where does Norgren stand today globally? Please give us a background about your company.

Norgren started its journey in 1927 with Carl Norgren in Denver, Colarado. Carl identified the latent need from industrial machines for lubricators, and that gave birth to first ever lubricator for pneumatic systems, along with practically inventing an entire industry. Over the last century, Norgren has maintained its focus on being innovative and providing answers to customer pain points.

Today, Norgren is present in over 75 countries with manufacturing facilities in 22 locations globally. From being the first producer of lubricator, Norgren is now an established brand for complete range of pneumatic products. It grew both through organic and strategic acquisitions over the years. Norgren is the umbrella brand for some of the most well known brands and market leaders in pneumatic industry across the world – Herion, Buschjost, Webber, Martonair, Watson Smith, Kloehn, and more.

Today, Norgren is present in over 75 countries with manufacturing facilities in 22 locations globally. From being the first producer of lubricator, Norgren is now an established brand for complete range of pneumatic products. It grew both through organic and strategic acquisitions over the years. Norgren is the umbrella brand for some of the most well known brands and market leaders in pneumatic industry across the world – Herion, Buschjost, Webber, Martonair, Watson Smith, Kloehn, and more.

Norgren itself is a part of IMI plc, a £2.1 billion (approximately $3.5 billion) size group listed on LSE, and is a FTSE 100 company. IMI is a global engineering group focused on the precise control and movement of fluids in critical applications. We work with leading international companies worldwide to deliver innovative engineering solutions to address global trends such as clean energy, energy efficiency, healthcare and increasing automation. At the heart of everything we do is our code of conduct, the IMI Way, which has been the most consistent factor in IMI’s longstanding business success.

When did the Indian operations of Norgren commence and how have you done since entering the market?

Norgren has been in India through two joint ventures since the 1980s. However, as a 100 per cent Norgren company, it came in 1997  post the acquisition of the Herion Group worldwide by IMI plc. The Indian subsidiary of Norgren is known as IMI Norgren Herion Pvt. Ltd. We have been at the forefront in our chosen target sectors such as Energy, Commercial Vehicles, Rail, Life Science and the F&B sector in supporting our customers and customer’s customer. In the last about 10 years, we have exponentially grown year-on-year at multiples of Indian GDP and industrial growth levels.

post the acquisition of the Herion Group worldwide by IMI plc. The Indian subsidiary of Norgren is known as IMI Norgren Herion Pvt. Ltd. We have been at the forefront in our chosen target sectors such as Energy, Commercial Vehicles, Rail, Life Science and the F&B sector in supporting our customers and customer’s customer. In the last about 10 years, we have exponentially grown year-on-year at multiples of Indian GDP and industrial growth levels.

Our current focus has been on increasing and strengthening our local manufacturing capabilities and footprint to be able to support our key customers to fulfil their needs related to JIT, on-time delivery and local support, and to deliver enhanced value. We are a ISO 9001, ISO 14001, OSHAS 18001 and have recently acquired TS 16949 and SIL 4 certification levels as well.

What are the USPs of Norgren India that differentiate it from competitors?

The pneumatic industry is unique, in the sense that it caters to each and every industry out there. Additionally, since it has such a widespread usage, the industry has inherent multiple and fragmented players.

Norgren was established on the platform of innovation and quality, and we have consistently improved and strengthened our processes and standards over the last century. Quality is a virtue that is ingrained in every process, product and service of Norgren. Though what sets Norgren apart are its world class Key Account Management through Sector Focus and Engineering Advantage expertise, which are central to differentiating ourselves from our competitors with end-user insight and the application of innovative technology. We are increasing our investment in these two areas to ensure we keep our customers and customer’s customer competitive and remain their partner of choice.

We believe that we are true partners to our customers when it comes to solving their problems around their automation needs. Our strength lies in our engineering mind and our job is to use it for the unique problems that customers face. This is what we call “Engineering Advantage”. One will find the complete range of pneumatic products with unsurpassed quality in Norgren’s kitty. But what gets us ticking is the unsolvable problem for which the customer needs a solution. Be it a unique solution to the pneumatic circuit, a change in product design, or even a differentiated service in logistics or paperwork, Engineering Advantage is at the core of Norgren’s working DNA.

Could you outline your approach for the Indian market? What are the sectors you focus on?

As I mentioned before, Norgren has grown through organic as well as strategic acquisitions. We have never aimed for being a brand which lies in the domain of a ‘me too’ supplier. Our focus has always been to understand our customers just as well as our own brand. This is why Norgren has invested a lot in understanding and choosing the sectors it wants to work in. Our acquisitions have also been in-line with the same strategic thought.

As I mentioned before, Norgren has grown through organic as well as strategic acquisitions. We have never aimed for being a brand which lies in the domain of a ‘me too’ supplier. Our focus has always been to understand our customers just as well as our own brand. This is why Norgren has invested a lot in understanding and choosing the sectors it wants to work in. Our acquisitions have also been in-line with the same strategic thought.

Every acquisition of Norgren is driven by two strategic questions – does the acquisition provide a unique technical know-how? Does it provide a sector-knowledge which is currently missing?

With acquisitions that answer the above questions positively, Norgren is now a brand conglomerate that retains the global sector know-how of various industries. And these are the sectors where Norgren focuses with its Engineering Advantage – commercial vehicles, energy (power and oil & gas), life sciences, Railways and food & beverage.

Kindly elaborate further on your focus on the commercial vehicle segment?

The commercial vehicle sector is one of our most important business units, not just in India but globally as well. We have more than 35 years of experience in the commercial vehicle industry, and all major OEMs are globally our customers and partners as well. We have developed a core set of products and technologies for the CV sector that have been proven over hundreds of millions of miles of reliable performance.

Norgren has six dedicated CV products manufacturing sites located in the UK, the US, Germany, the Czech Republic, Brazil and Shanghai. Norgren India is also a fast upcoming site for manufacturing. A world class dedicated CV KAM team is in operation around the world, placed strategically to each of our target truck customers & Tier-1s. This team is responsible for connecting across the globe to ensure continuity of support for large global customers, which live and breathe the industry. We understand the market trends, emissions standards, regulatory requirements, safety standards and specifications that matter to truck manufacturers, Tier-1 OEMs and the end users.

We also have a dedicated team of R&D engineers working on future technology platform for the truck industry placed at the MIRA test facility in the UK that works on technology development envisaged to be in the market place in next 5 to 10 years.

In India, Norgren has branches across all major cities with its head office in Noida, to cater to the NCR region. Our key account managers and sales leadership are strategically located near the customers.

Who are the major OEM customers in the domestic and global markets? How do you plan to leverage on your relationship with global OEMs and work with them in the Indian market?

The commercial vehicle sector in India is led by Tata Motors and Ashok Leyland, and we are closely working with both of them for developing unique solutions. We are supplying engineering solutions to Volvo, SML Isuzu, Eaton and WABCO as well, in India.

Globally, Norgren is a partner to all the leading CV manufacturers and OEMs including Volvo, Daimler, MAN, Scania, ZF, Cummins, Ford, Knorr Bremse, Eaton, BorgWarner and DAF, to name a few. Our global customers usually demand extension of our businesses wherever they go. This is the reason why Norgren inaugurated its Asia Technical Centre in Shanghai in 2008, and we are growing its extension engineering centre in India. We have won recent contract with Volvo in India for Control Valve solutions. Scania will continue to import our products from Europe for some time though we are working closely with Foton for developing future technologies in India.

Could you share details on specific projects with your OEM customers wherein you have delivered ‘Engineering Advantage’ to them?

We have done special projects with many OEMs in India to build Engineering Advantage solutions which goes into critical applications like transmission and chassis pneumatic control.

One of our customers wanted a special actuator for transmission application that had a limitation on the size and stroke. Obviously you need a solenoid valve to control it, and as per the OEM plan, the solenoid valve would have been mounted on the chassis which would have created assembly complications. We proposed an engineering advantage solution where we integrated the actuator, one of our best cartridge valves and a push-in fitting. This solution saved a lot of tubing, routing, additional fittings and brackets. More importantly, the customised solution resulted in saving of significant assembly time, and this part is in serial production today.

Similarly, another customer wanted high flow (2 mm – 3 mm orifice size) solenoid valves for PTO, diff lock, exhaust brake, axle lock and power shift application. We offered them our newly engineered ISIS valve that could be racked to save on inlet fittings and common mounting bracket and enhance truck aesthetics.

What about the outlook for the CV sector in India and how does Norgren plan to be part of the expected growth?

It’s no news that these are some of the toughest times that most of the heavy industries are facing. The commercial vehicle sector is no aberration, and we have seen significant drop in the sales figures of all the major OEMs. Though, at Norgren, we believe this to be a temporary phase which will not last long.

Having said so, there are quite a few policy changes in the pipeline that will provide a positive impetus to the commercial vehicle sector. The infrastructure growth in India has been tremendous in the last decade, and we foresee the same to continue once this temporary lean phase wears out.

With much better roads and highways, the logistics industry demand for vehicles with higher GVW will increase, as has been the trend in other developed economies. This will require much more advanced and technologically robust pneumatic systems. This will also initiate the trend for relatively new concepts like axle-lift systems at a higher adoption rate. Also, the implementation of emission policies is yet another area which should give us growth options.

Despite the market slowdown in 2012, Norgren recorded healthy growth over 2011. This was made possible only due to the increasing contribution per truck for our solutions. Even during the slowdown, we are continuously working with our OEMs to develop new solutions. Also, we are continuously engaging in leveraging the expertise from global know-how and preparing ourselves for future technology that India will require. With our increasing customer base, Norgren will continue to register exponential growth in the next 5 years.

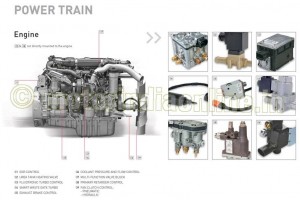

A few unique offerings from Norgren for the CV segment:

* High flow engine / transmission / chassis solenoid valves for applications like exhaust brake, PTO, differential lock, range shift, power shift and engine coolant control.

* Robust and reliable proportional PWM-controlled valves for engine EGR, waste gate, VGT and exhaust brake control.

* Simple in design and use push in fittings and check valves for air brake system.

* Safe and easy to operate bus door pneumatic control systems.

* Performance defined and customized solutions like composite manifolds for chassis application, range shift inhibitor / reverse gear inhibitor for transmission application and others.

* Pneumatic seat control solutions, including auto seat height adjustment system.

* Thread-based fuel tank caps for low leakage and fuel tank breather with safety option.

* High-end load body tipping valves (with and without PTO lock).

* Air suspension control systems for passenger carriers.