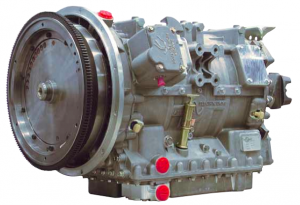

The updated Allison Transmission H40EP and H50EP hybrid systems feature enhancements, including Allison Fourth Generation Electronic Controls, a second-generation Dual Power Inverter Module 2 (DPIM2) unit, the latest Energy Storage System 2 (ESS2), and new Allison HyValue performance features. Furthermore, Allison has taken the next major technological step with the introduction of DC to DC converter capabilities.

The company’s latest microprocessor controls feature hardware which is common to all its high-volume commercial transmissions. The controls have greater processing power and memory capability with memory expansion that allows for further technology evolution.

The company’s latest microprocessor controls feature hardware which is common to all its high-volume commercial transmissions. The controls have greater processing power and memory capability with memory expansion that allows for further technology evolution.

The DPIM2 unit features enhanced internal hardware with superior redundancy for greater reliability. Externally, this new unit is fully interchangeable with all prior production units, giving users maximum maintenance flexibility.

Allison’s second-generation ESS2 utilises the latest nickel metal hydride battery cell technology from Panasonic. The high-capacity cells are common to both the Allison Hybrid H40EP and H50EP Systems. Allison has used Panasonic nickel metal hydride batteries in the ESS since the start of production in 2003, and it has proven itself in more heavy-duty hybrid buses than any other brand or battery chemistry.

The EV Drive module is a two-mode parallel hybrid that automatically delivers benefits typical of parallel hybrid or series hybrid technologies. The continuously variable drive features an infinite number of ratios and automatically adjusts ratios to operate at optimum power curves to attain the best performance and fuel economy.

The EV Drive automatically chooses one of an infinite number of ratios to run engines at their most efficient points for low fuel consumption, low emissions and low noise.

The H40/50EP System also has the Allison HyValue performance features HyGain, HyIdle and HyTraction. With Allison’s HyGain feature, fleets can adjust the acceleration rate to fit their operating requirements. Adjusting HyGain downward further increases the fuel economy. HyGain allows OEMs and fleets to adjust bus acceleration to one of five settings. Lowering the setting reduces acceleration and further reduces fuel consumption, as well as lowering engine speed and noise.

DC to DC converter

Allison has also taken the next major technological step with the introduction of DC to DC converter capability. A solid-state converter eliminates the traditional alternator to provide greater reliability while lowering operational costs and maintenance issues.

The DC to DC converter will not use the ESS2 for storing energy, thereby maintaining outstanding hybrid battery life. The converters have the nickname of “beltless alternator” since they are solid-state devices that maintain electrical efficiencies of 91-95 per cent. Having such a high electrical efficiency, the converters replace large belt-driven alternators and do not require any type of mechanical belt drive system or associated maintenance requirements.

The DC to DC converter powers not only traditional 12/24-volt loads, but also accommodates the electric radiator, charge-air-cooling and hybrid drive electric fans providing better efficiency and eliminating hydraulic fan drives.

There are over 4,600 buses and coaches equipped with the Allison Hybrid EP System in operation around the world providing over 600 million km of reliable, fuel-efficient and low emission service. These hybrid buses are operating in over 216 cities worldwide and have saved an estimated 75 million litres of fuel as well as eliminating over 197,000 metric tons of CO2.