The aerial work platform (AWP) market in India is at a great inflection point. In this regard, Gemini Power Hydraulics is keenly exploiting the benefits of advancements in technology, safety and the need for improved duty cycles by operators to make a great case for themselves in the sector on the verge of exponential growth, writes Rajesh Rajgor

In the last 25 years of its operation, Gemini Power Hydraulics has been in the business of distributing niche applications and solutions that ease lifting, bolting, bending, pulling and handling heavy metals in varied industries like manufacturing, energy, railways, hospitality, etc. Apart from the several technologically advanced products that the company has supplied to these industries, they have made a mark in AWPs (aerial work platforms), namely in truck-mounted applications. The company ventured into AWPs in 2008 through their partnership with French company Haulotte.

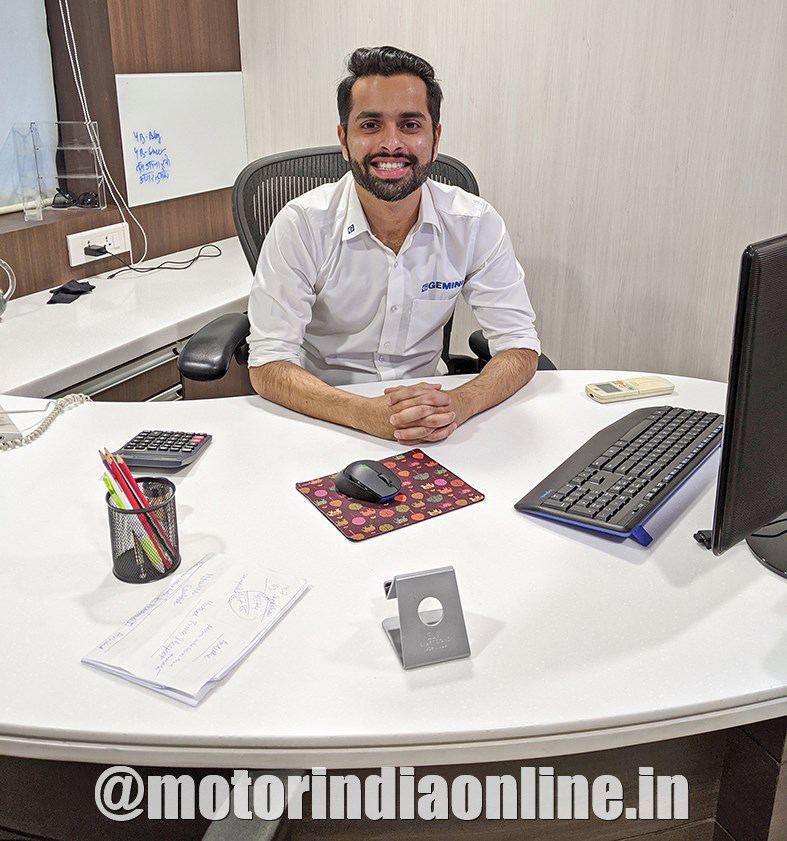

“The ambition was to provide technologically beneficial products to customers. We noticed there was a lot of gap in the market with people using old mechanical machines that do not rank high on safety or efficiency. We spent time with customers to make them understand the benefits of our AWPs in the first couple of years. While distribution still remains big part of our business, chassis-mounted application – an important branch of AWPs – drew great interest from customers,” says Aahan Sethi, Director, Gemini Power Hydraulics.

Reaping benefits in a market still maturing to advance technologies, Gemini Power Hydraulics leveraged on the growing sturdiness of the small commercial vehicles (SCVs) and intermediate commercial vehicles (ICVs) in India. “India is one of the biggest manufacturers of ICVs and SCVs in the world. We wanted to leverage this opportunity with our research and development and service network to develop top-class products. In the last six years we have had 100+ machines mounted on these vehicles as mobile AWPs. Our pan-India service network offering seamless connectivity to our customers with OEM-trained technicians provides remote as well as on-site diagnostics,” Aahan adds.

Industry First with Gemini Touch

According to the company management, the market has been stagnant for over a decade and needed a path-breaking product. Gemini Power Hydraulics’ LEVO, established on a small commercial vehicle (Tata Ace Mint) is their first entrant into manufacturing of chassis-mounted aerial work platforms. This customer-centric product’s core vision is to innovatively fulfil the technical needs of the customer. Elaborates Aahan: “It is a product born to be disruptive in a market which has been stagnant over the last 10 years with outdated and primitive technologies. The launch of this product resonates with the inflection point of mechanisation in the country, where the demand for aerial access platform is on the rise.”

“It is also launched in line with the new BS VI emission norms in the country, with new chassis and specifications out in the market,” he adds. LEVO is touted as the company’s self-reliant truck-mounted aerial platform (TAWP), a truly ‘Make in India’ product. “While LEVO complies with the stringent EN 280 and CE safety standards, it is exclusively designed and built to suit the tough Indian working environment. The machine is extremely nifty and designed to work not just in busy urban areas but also in the by-lanes without disrupting the traffic. Along with providing the equipment, we have provided ‘industry first’ service diagnostic, telematics and IoT solutions, thereby offering a one-stop shop for all customers’ needs and concerns,” Aahan states. With LEVO, Gemini Power Hydraulics aims to raise the bar and set a new standard for TAWPs in India.

The philosophy behind this product is three-fold: economical for the owner, ease of use and safe for the operator whilst trouble-free maintenance for service. Says Aahan: “LEVO at 11 metres provides the highest attainable height mounted on the most compact chassis available. Where the competition was able to achieve a mere 8 metres, we have surpassed that and provided the luxury of 200 kg basket capacity, all the while maximising the outreach and productivity of the machine and minimising lane occupancy and tail swing during operations. We were able to achieve this by using high tensile STRENX® steel, IP-65 certified components, high-quality cylinders and slew drives – all this packed into a frame which is lightweight and robust.”

Designed for Sustainability

Gemini Power Hydraulics is akin to visionaries, where new technologies and equipment are brought into the country ahead of its time. This is deeply entrenched within the values of the organisation which emphasise on customer focus, innovation, integrity, value-addition and wellbeing. “Our plan was to provide a solution that would cater to all the demographics of people, build a balanced ecosystem between the customer, OEM and manufacturer,” Aahan states. This penchant for technology led them to unique design partners in order to fulfill their core objective of providing ‘hassle-free’ solutions. It also led them to tie up with leading brands such as Haulotte (France) for self-propelled aerial access platforms, Palazzzani (Italy) for spider-mounted aerial access platforms and CTE (Italy) for truck-mounted aerial access platforms.

“Our design process and philosophy arise from being a customer-centric organisation. This resolution ensures a general increase in the quality and standard of equipment provided. We focused on the pain points of the customers both financially and from an operation point of view. We also made an intense effort to understand the requirement of not just the owners but the operators and the maintenance people as well. With LEVO, we looked to cause a disruption and bring people up to the standard of working present across the globe. The idea was not just to build a solution, but come up with a ‘LEVO’lution,” Aahan says.

While Gemini Power Hydraulics’ nascent introduction as manufacturers of TAWPs into the market puts them in a great spot, they are evaluating each step before bolstering and ramping up productions. “Currently our manufacturing comes under the wing of ‘distribution and assembly’ and shares the same infrastructure i.e. overheads, space, team, etc. Our current capacity is that of one unit a week, which equates to four units a month and therefore about 50 units a year. Our plan is to expand into a much larger facility where we are targeting realistic numbers. We expect the capacity to increase to two-fold in a years’ time followed by steady growth. Our greater interest lies in creating a manufacturing supply of chassis-mounted solutions in India and eventually strengthen our visibility and presence in South East Asia, Africa as well as other European countries,” Aahan reveals.

Sales and Service

A pan-India, multidisciplinary team supported by regional and services managers guide Gemini Power Hydraulics to tackle any challenge that comes their way. Their team members are OEM-trained and certified across various skill-sets such as hydraulics, welding, electronics, etc. “We believe service is the heart and soul of our business. As the lynchpin of our organisation, we have an organised inventory, packaging and logistic system to service customers across our entire portfolio. For us, service is always a driving factor and one of the primary reasons why people choose Gemini Power Hydraulics over the competition,” Aahan informs.

“Currently, we have over 700 machines in the markets and we offer both annual as well as comprehensive maintenance packages,” Aahan adds. “We have about 500+ units under AMC or CMC and have a great rate of customer retention. Service is one of the primary revenue generators of our organisation that enables us to grow and expand,” he further asserts. Clearly enough, the key benefits of using a Gemini Power Hydraulics’ product is less equipment downtime and lesser headaches during maintenance. Emphasis on service indicates that the company is raising the bar for AWPs in India. “We engage and enable the customer to realise the value of their purchase and reap all the benefits of it. By offering minimum downtime, we ensure the machines operate with 95% efficiency. Some of our equipment comes with five-year warranty. We place confidence in our products and technologies to ensure we deliver nothing but the best to the customer. Our AMC and CMC proposals are packaged attractively in three categories such as bronze, silver and gold using a service matrix i.e. usage versus distance versus performance charts. We are one of the few companies that offer OEM-skilled and trained service technicians with the option of remote as well as remote diagnostic solutions,” Aahan informs.