An ex-Soviet professor-turned Ukrainian industrialist has come out with his unique patented technology and equipment for recovering heavy-loaded crankshafts of trucks, ships and locomotive diesels.

Mr. Alexander G. Saakov, an academician from the Kazakh Academy of Sciences, Russia, and the CEO of LLC “TOPAS-Technology”, who is in the sophisticated technology market since 1994, indulged in development of hardware technologies and materials to improve equipment reliability in sectors like automotive, railway, shipbuilding and oil & gas.

This unique technology is apt for the application of dense, wear-proof and corrosion-resistant coatings on the working surfaces of parts and components of heavy-loaded crankshaft locomotives, ship components and automobiles; spaces for bearings of locomotive and wagon wheel pairs and pumps; and mine equipment. It can be used to restore and improve the reliability of parts of the friction pair of most parts, such as shafts in stern duct and parts of pumps that are subjected to friction.

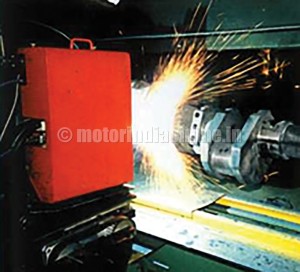

With this latest coating technology of work surfaces, crankshafts are renovated by a fundamentally state-of-the-art new method of arc metallization in a supersonic jet of high-temperature combustion of air and natural gas.

In this case, in comparison with conventional processes, the kinetic energy of the sputtered particles is increased by four-five times and the flight speed from 70-150 m/s to a rocketing speed of 250-300 m/s. Compared with a typical arc spraying process, the degree of burning carbon falls from 40-60% to a down-to-earth 3-6%, and silicon and manganese from 20-25% to an unimaginable 2-3%. The micro-hardness of the resulting high-speed quenching from the liquid state is increased by an outstanding 40-60%.

The residual compressive stress formed during the coating process makes it difficult to crack formation and increases the fatigue resistance of parts as well as the durability of the material. The resulting coating has high tribological characteristics and anti-friction properties and low coefficient of friction throughout the wide range of workloads.

A distinctive feature of these coatings is the special structure and low (~ 1.5%) porosity which prevents shrinkage of the coating and enables uniform distribution of free graphite. As a result, the coating withstands prolonged cyclical high loads and overloads which usually exist during the working of powerful diesels.

Besides, because of the residual (2%) porosity uniformly distributed in the volume of the recovered layer, coating keeps the oil that is vital for starting a cold engine. And free graphite, during operation, comes to the surface and fulfills the role of a hard lubricant.

Mr. T. Vivekanandan, an automotive technocrat from the Moscow Automechanical Institute, who has specialised in internal combustion engines, representing as the patent holder in India, says he has extensive experience in the implementation of the equipment, technology and materials in countries such as Latvia, Ukraine, Moldova and Russia.

He says: “Along with the restoration of worn necks of crankshafts increases the longevity of their work in the friction pair with bronze and steel – aluminum inserts by an astonishing 2 to 3 times. Renovated crankshafts are more reliable than the new ones and can reach over one million km mileage. What is most remarkable is the fact that in extreme cases of emergency like stop of oilfeed, the presence of abrasive in the coating shows great vitality in comparison with the base material of the crankshaft”.

Mr. Vivekanandan who is the official representative of the Moscow Automechanical Institute in India can be contacted at thiagarajanvivekanandan@gmail.com