Hendrickson is known the world over as a leading manufacturer and supplier of suspensions, axle systems, auxiliary lift axle systems, parabolic and multi-leaf springs, and bumper and trim components to the global transportation industry. As urban population trends continue to rise, a tremendous opportunity exists for buses to satisfy the transport needs of the growing population in a safe, reliable and comfortable manner. Bus manufacturers are challenged with providing solutions that can maximize the number of passengers, maintain the highest level of durability and to ensure passenger safety and comfort.

Hendrickson stands ready to support its OEM partners, developing solutions that exceed expectations for performance and durability. Most of all, Hendrickson has a rich history of providing the right product for the right application.

Understanding the application

Before design work begins, it is essential to understand everything possible about the environment that the bus will be operating in. Passenger & equipment loads, environmental factors, road conditions, and braking cycles are a few of the factors considered when designing products for this market. Hendrickson goes to great lengths to collect real world data to determine the specifications necessary to maximize performance and durability. Extensive data collection from the field along with customer interviews and site visits enable Hendrickson to get a true understanding of what a product must endure while in operation.

Hendrickson’s goal is to be positioned as an extension of OEM engineering, product development and field sales & service teams. Hendrickson invests in the most advanced testing and validation tools to bring even more value to bus OEMs, achieving shortened development timelines, lowering development costs and improving overall vehicle performance. It leverages its technical expertise to execute vehicle integration projects and to bring customized solutions for specific applications.

Total vehicle approach

Once market and customer needs are identified, the work of designing the ideal product begins. During the design creation phase, Hendrickson uses the most advanced engineering software to model specific components, identify stress points and simulate suspension performance in different application environments and load conditions.

Hendrickson takes a total vehicle approach, understanding how products are influenced by other chassis components and what factors can change performance. As the design matures, sophisticated in-house research and development facilities are utilized, featuring numerous test rigs designed to simulate real-world scenarios, to ensure that reliability, performance and quality objectives are met before finalizing the design. Once a suitable design has been created, track testing commences and final design refinement occurs as the product endures tests that emulate real world conditions and are correlated to industry or OEM test standards.

Product portfolio

Designed with the passenger, driver and service technician in mind, Hendrickson produces robust solutions that feature the ride quality, vehicle handling and stability required for bus applications around the world. Hendrickson maintains a complete portfolio of products for a range of bus applications.

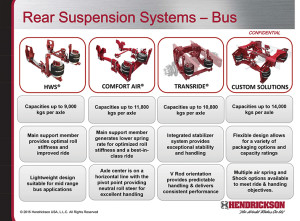

Drive axle air suspensions

Bus manufacturers & operators realize the advantages of air suspensions and the migration to air has begun. Buses are expensive and as with any piece of expensive equipment, priority should be taken when specifying components that affect the performance of the vehicle, the life of the vehicle, the frequency of maintenance and the comfort and safety of the passengers and operators. Hendrickson maintains a line of drive axle air suspensions systems that meet these needs, providing years of reliable performance.

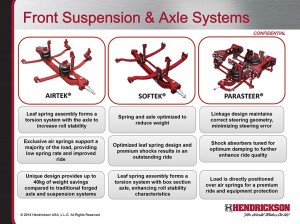

Steer axle & suspension systems

Much like rear axle drive suspensions, air ride front axle suspensions have emerged as a popular choice in bus applications. Hendrickson has advanced air ride technology to provide a smooth comfortable ride while delivering exceptional handling and stability.

When reviewing front axles and suspensions, it is important to consider three main areas to ensure optimal performance and durability. Historically, the design and type of steer axle, suspension and clamp group are treated as individual components. Hendrickson takes a systems approach to the front axle and suspension by integrating these primary components resulting in designs that are weight and cost efficient while optimizing performance. The centerpiece of Hendrickson systems is the STEERTEK NXT steer axle, the markets only fabricated non-drive steer axle.