MOTORINDIA correspondent Rajesh Rajgor spoke to Anuj Kapuria, founder and CEO, Hi-Tech Robotics Systemz to understand the potential of high-performance automated products and solutions for people as well as goods’ transportation

Hi-Tech Robotic Systemz is a bootstrapped robotics company in India, focused on developing products for the next generation of mobility with state-of-the-art autonomous, driver-assistive technology and mobile robots for both people and material transportation. Their mission is to deliver scalable, smart, autonomous and assistive systems through disruptive business models. The company has made a name for itself as a leading manufacturer and supplier of a high-performance range of industrial automation, palletizing systems, automated guided vehicles, defence robotics, remotely operated vehicles, etc.

Explaining the potential and scope of robotics in India’s manufacturing setup as well as for assisting mobility, Anuj Kapuria, Founder and CEO, Hi-Tech Robotics Systemz, says: “India’s growing stature as a manufacturing hub, which is one of the key contributors to Indian economy, opens up a huge potential market for robotics. The robotics Industry has witnessed a further push because of the ongoing pandemic which demands physical distancing as a new normal, thus leading to a change in the way customers consume products and services. It has given the industry significant exposure to work under such challenging conditions where robots can be a real support system to revive the industry and the economy.”

“The robotic industry which stood at 5,000 units till last year is expanding at a CAGR of 14.1% to reach 11,760 units by 2025, showcasing a phenomenal journey ahead for the sector,” he adds. The company also has a strong focus on revolutionary road logistics’ vision analytics solution – autonomous and driver assist systems (ADAS). Considered as a pioneer in the robotics industry of India with a 200+ team size across India and over 120 people working in research and development, the company has filed more than 100 patents along with 350+ plus active deployments of ADAS products for the next generation of vehicles.

Driver and Occupant Safety

“For ADAS, we started off with an ‘OEM first’ strategy. This was a deliberate strategy where we worked with the world’s largest commercial vehicle (CV) maker. We competed against Japanese and German suppliers and were able to beat them, not just in price but also in performance. We went through a very stringent validation protocol with over 5,00,000 km of testing to build a very rugged, automotive grade product. Once we did that, we then started distributing it in the aftermarket. We are working with all major OEMs but that will still leave over 80 lakh trucks on road. So that’s the reason we focused on key segments in the aftermarket,” shares Kapuria.

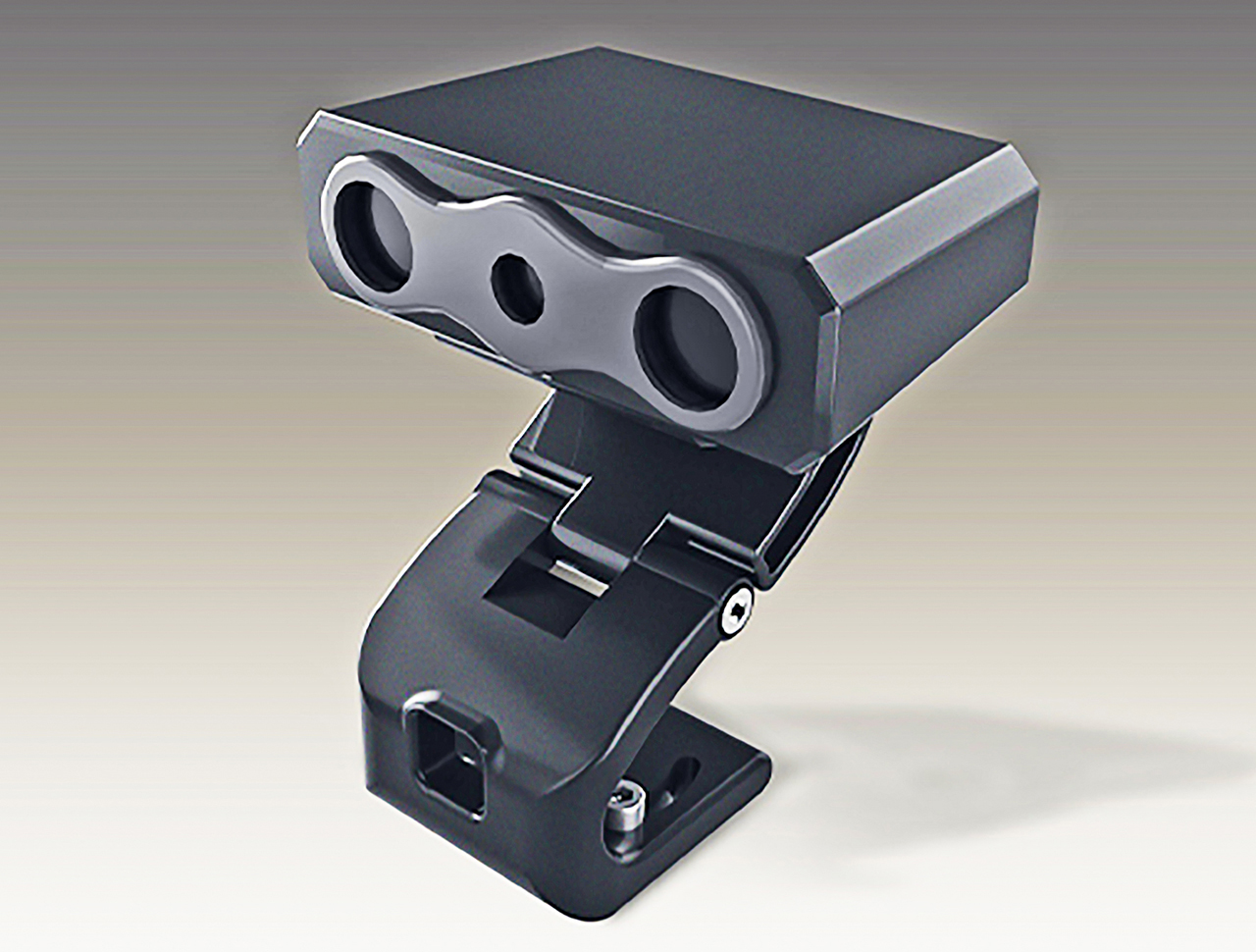

Hi-Tech Robotic Systemz’ ADAS offerings are primarily built into the vehicle in collaboration with OEMs, but the company is also beginning to offer aftermarket solutions. The next-generation ADAS’ leverages wireless network connectivity to offer intelligent dashboard giving an overview of comprehensive fleet performance. The company’s offering – Novus Aware – is an ADAS for driver state monitoring. It can detect and raise alarms on driver’s inattention while driving. It caters to scenarios like drowsiness, strafing and mobile phone usage. This product record logs of unsafe incidences for fleet manager analysis and sends data to the fleet management system.

In 2018, the company tied up with Daimler India Commercial Vehicles for their Bharat Benz truck range for Novus Aware that uses artificial intelligence and computer vision technologies to build an intelligent model of monitoring driver behaviour that includes such features as eye movement, face, head, gaze and other natural cues to infer whether a driver is in a safe driving state or not. Apart from Novus Aware, the company also has in its product basket the ‘Novus Pilot’, an active collision mitigation camera system. Novus Pilot offers safety features like lane departure warning, forward collision warning and can interface with OBD II and provide alerts and health analytics of the vehicle based on driving behaviour. The product has seen a lot of traction from the commercial and passenger vehicle OEM community and the product is undergoing exhaustive trials with major OEMs.

Thousands of these products are now being fitted on aftermarket fleets as well owing to the features mentioned above. The company has also focused on key aftermarket segments like express delivery, e-commerce delivery, FMCG sector and the petroleum, oil and gas segment where turnaround times are very important. “If an accident happens in any of these segments, the collateral damage itself can be huge. A lot of accidents happen because of driver distraction, drowsiness and inattention,” Kapuria informs.

“Therefore, we have been very precise about the kind of segments that we pursue in the aftermarket. It’s a huge market and we will continue to build our products like mobile phones were even if the hardware is fixed we can push a software upgrade and a new feature. Once we put our device in a truck we can just do an over-the-air (OTA) update for long-term association with clients and unearth the full potential of the device,” he adds. Some of the other sectors the the company is looking at includes passenger vehicles and buses in the domain of public transportation. “It’s not only about driver monitoring but also occupant monitoring because occupant safety is as much important as driver safety. We are thus seeing some traction in terms of buses as well as taxis. This will chart out our growth map of the coming years,” Kapuria states.

Robots on the Shop Floor

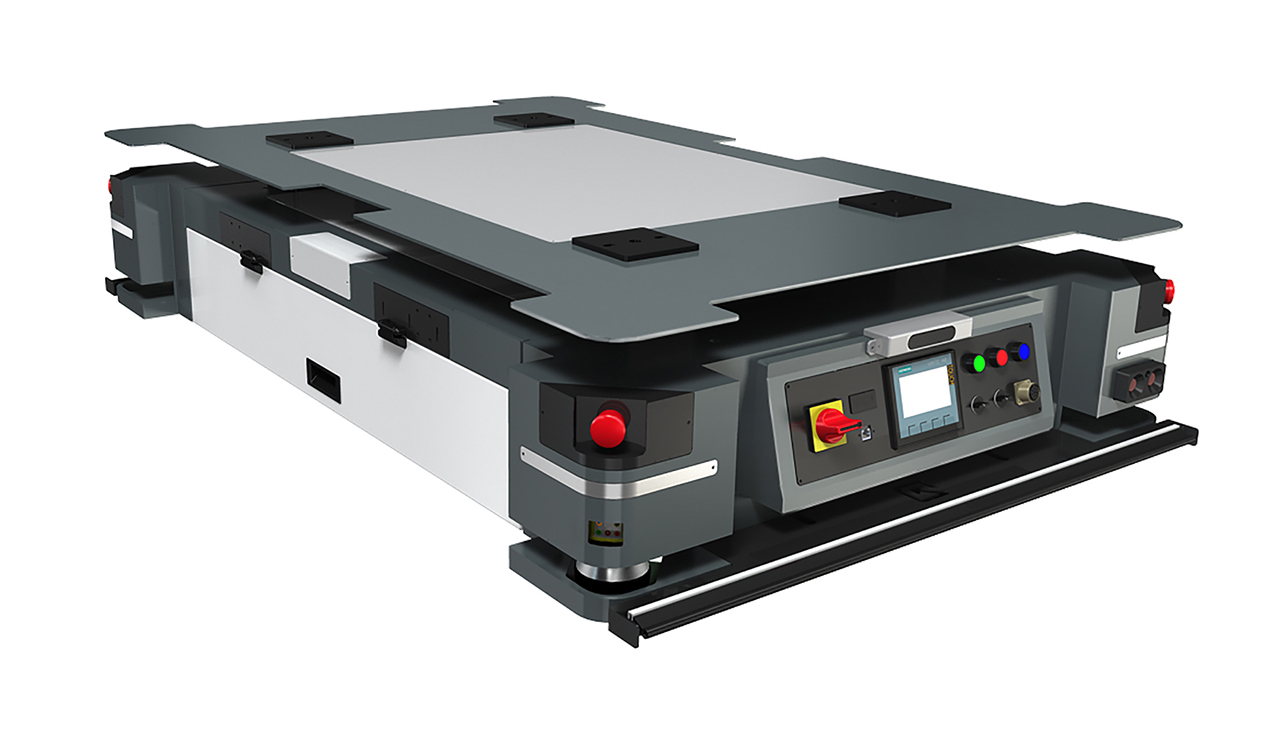

For the uninitiated, Hi-Tech Robotics Systemz, which offers a revolutionary intra-logistics solutions, has enabled Industry 4.0 with autonomous mobile robots (AMRs) for warehousing and manufacturing facilities with a connected Industrial Internet of Things (IIoT) framework. Explains Kapurias: “From a manufacturing standpoint, I think resilience, anti-fragility and the ease of processes is being looked at very seriously now. We are an industrial autonomous and AI-based technology company and among the first ones to have started collaborating with mobile robots, autonomous vehicles, ADAS systems indigenously in the country.”

“We are trying to transform the supply chain for our customers through two main business lines of ours – ADAS and mobile robots for shop floors. Our mobile robots are positively impacting the internal logistics of a plant or warehouse. This includes material transfer, requiring less of human intervention and mobile platforms, much like a small electric vehicle, which will run around in your factory and deliver material at the right place at the right time. This optimises the efficiency, reducing overall material handling cost by up to 30%,” he adds. The company has filed registered over 100 patents in the field of self-driving cars, artificial intelligence and robotics.

“Our latest product is an autonomous mobile robot for automating material movement in manufacturing units capable of carrying unit load, tugging and tunnelling. It can handle loads from 100 kg to 1,500 kg. Our products and solutions are utilised for material handling automation, material handling robots, supply chain automation, warehouse automation, industrial automation, vehicle automation system and much more,” he adds. There is also a lot of scope for automated guided vehicles (AGVs) on the manufacturing shop floor today than ever before to be able to reduce irregularities and iron out processes.

In fact, with Industry 4.0, many companies are looking at complete autonomous mobile robots. With over 300 deployments of AGVs, Hi-Tech Robotic Systemz is among Asia’s largest manufacturer of AGV for material movement. Elaborates Kapuria: “AGVs are automated and this requires the installation of adequate infrastructure to allow them to navigate whereas AMRs are essentially freely moving robots, much like humans. The best part is they don’t require human-free areas. Thus, there is no need to eliminate human presence on the shop floors. They are perfect for all the non-essential tasks that are otherwise carried out by humans.”

Bolstering Research and Development

It is obvious that a company which focuses so much on technology will have a strong research and development setup. Hi-Tech Robotics Systemz dedicates over 40% of its work force to the research and development of new products and systems. With highly qualified professionals on its team and to stay ahead of the curve, the company nurtures the talent and trains them to be at the forefront of cutting-edge of technology. Kapuria shares: “From a capacity standpoint, I think we have invested in significant capacity already and yet given the demand there is always a need to keep upgrading the capacity. Thefore, we are looking at investing over Rs 100 crore in the next 12-18 months.”

Although the company is currently overwhelmed with the domestic demand, it is not discarding opportunities and tie-ups to scale up its presence in the overseas’ markets. “We are looking at growth internationally. We know we can be strong in geographies like Australia, South Africa and some parts of Europe, North America and Canada. We are definitely much more competitive and have seen a lot of traction building up for our industrial as well as automotive products. We will be investing further to ensure that we have the requisite support networks to cater to overseas’ demand,” Kapuria reveals.

Meanwhile, as much as the company focuses on localisation and being self-reliant, it does have to deal with certain realities. “Some high-end sensors and electronics for radio technology are yet not manufactured in India and we can’t find sources that can match our requirements. Hence, we have to import those parts. Of course, we did find a few alternate sources, especially during the tough supply chain times imposed by the pandemic and lockdown. It helps to have multiple sources and thankfully since we design our own products all of our electronics are embedded in-house accordingly. Thus, we do have a lot of flexibility to change and use alternatives that many of our competitors may not have,” Kapuria states.

Another important segment that Hi-Tech Robotics Systemz is keen on is defence. Kapuria feels that the company could make a tremendous impact in this segment and help the defence forces with customised products. “A lot of our technology of autonomy is like the backbone for unmanned ground vehicle programs for the Indian defence sector. We have worked a lot with Indian defence research and development organisations. Some of our robots are being used specifically for counterinsurgency, explosive disposal and bomb disposal type of missions. And we continue to support that and we would love to contribute as much as we can in that sector, whenever the demand arises,” he concludes.

—

“India’s growing stature as a manufacturing hub, which is one of the key contributors to Indian economy, opens up a huge potential market for robotics. The robotics Industry has witnessed a further push because of the ongoing pandemic which demands physical distancing as a new normal, thus leading to a change in the way customers consume products and services. It has given the industry significant exposure to work under such challenging conditions where robots can be a real support system to revive the industry and the economy.

– Anuj Kapuria, Founder and CEO, Hi-Tech Robotics Systemz