Pioneering the Future of CV Safety and Sustainability

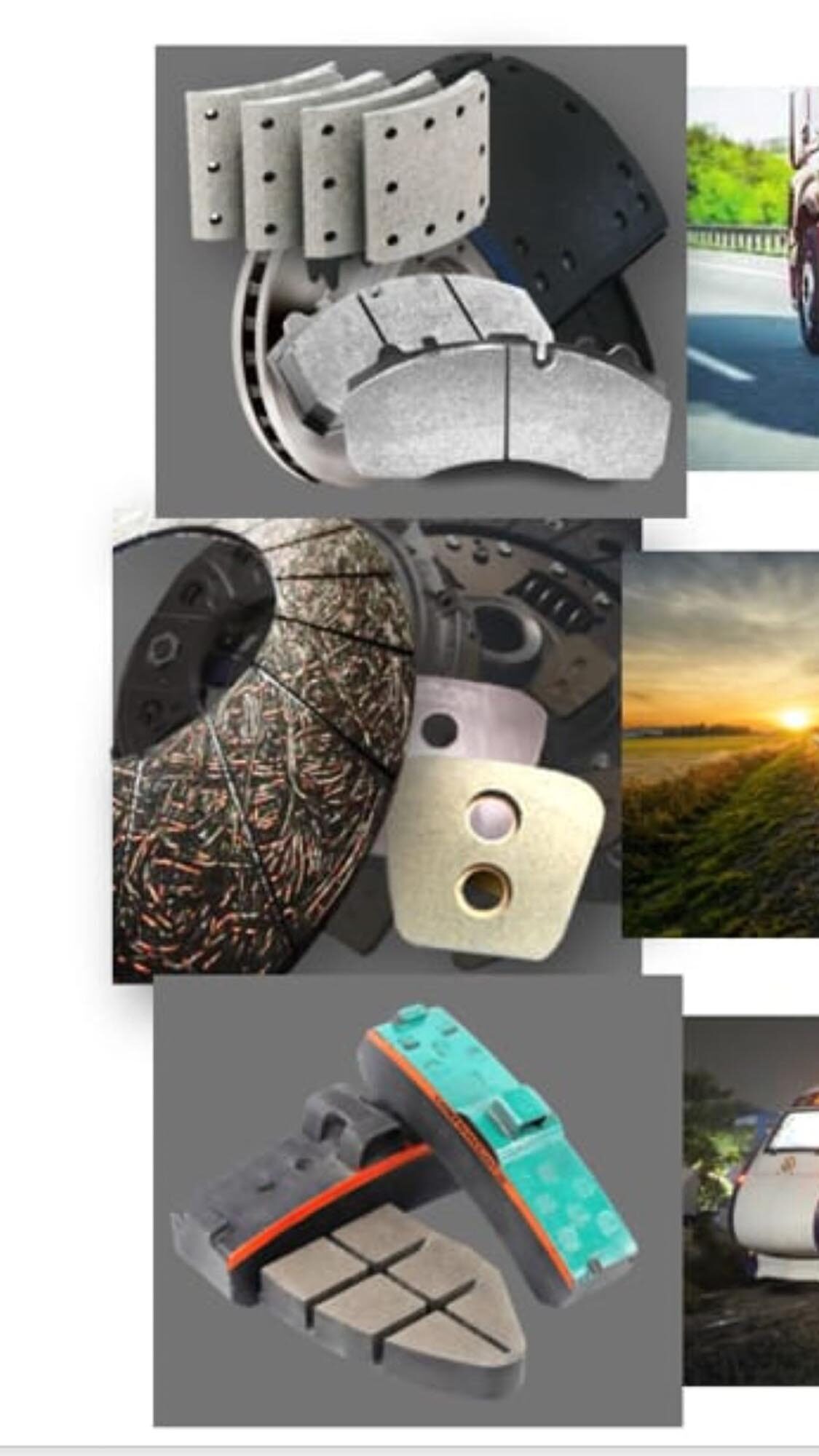

As the commercial vehicle industry evolves to meet modern transportation demands, the need for reliable and high-performance brake linings and clutch facings has never been more critical. Hindustan Composites Limited (HCL) is at the forefront of delivering innovative solutions that prioritize safety, durability, and efficiency.

Founded as Hindustan Ferodo Ltd in 1964 and renamed as Hindustan Composites Ltd. in 1994, the company has established itself as a pioneer in friction technology. With a diverse product portfolio, HCL caters to multiple sectors, including commercial vehicles, passenger cars, tractors, railways, and industrial applications. Its offerings include brake linings, clutch facings, clutch buttons, moulded roll linings, woven roll linings, brake blocks / disc pads for railways, and wet friction plates for tractors and off-highway equipment.

A Strong Focus on Innovation and Sustainability

Hindustan Composites has consistently invested in research and development to enhance the performance and durability of its friction products. A key focus for the company is developing sustainable, environmentally friendly solutions that align with evolving industry standards and regulations.

The brake lining industry has seen significant transformation in recent years, driven by the growing demand for commercial vehicles, stricter safety norms, and changes in the Central Motor Vehicle Rules (CMVR). To meet these regulatory requirements, brake lining formulations have undergone substantial advancements. HCL has risen to these challenges, leveraging its expertise and robust R&D capabilities to remain ahead of the curve.

The company operates multiple manufacturing facilities and a well-established technology centre staffed by experienced R&D engineers. These facilities are dedicated to continuous product improvement and the integration of global advancements in friction technology.

State-of-the-Art R&D

Hindustan Composites’ R&D center plays a pivotal role in pushing the boundaries of brake lining technology. Key features of this facility include:

- Advanced Testing Laboratories: Capable of simulating extreme operating conditions to ensure products meet the highest safety standards.

- Material Science Innovations: Teams focused on optimizing wear resistance, heat tolerance, and environmental impact.

- Prototyping Capabilities: Rapid prototyping tools enable quicker market deployment of new solutions.

- Data-Driven Development: Performance modelling software ensures consistent and reliable results.

Collaboration with global industry leaders further strengthens HCL’s R&D efforts. The company has forged partnerships / collaborations with Advics Japan for Disc Brake pads, TBK Japan for CV brake linings, Bendix Mintex for Clutch facings pads, and Hongqi China for oil-immersed brake discs tailored for tractors and off-highway equipment.

Excellence in Manufacturing

HCL’s manufacturing processes are designed for precision and sustainability. The company employs state-of-the-art automation to ensure uniformity, accuracy, and quality control across all production stages. Tailored solutions are developed in close collaboration with OEMs and fleet operators to address specific performance requirements.

A commitment to sustainable practices is evident throughout its operations, from using eco-friendly materials to reducing waste. The company is also aligned with global safety standards, ensuring that its products comply with certifications like ECE R90 and FMVSS 121.

Recognitions and Certifications

HCL’s dedication to quality has earned it numerous accolades from OEMs and other customers as a trusted supply partner. Its brake linings undergo rigorous testing protocols, including fade resistance, shear strength, and thermal stability, reinforcing the company’s reputation for safety and reliability.

Customer-Centric Approach

Hindustan Composites places customers at the heart of its operations. Technical support, training sessions for fleet operators, and robust post-sales services are integral to its approach. This unwavering focus on innovation and customer satisfaction has solidified its position as a leader in the brake linings market for commercial vehicles.

Pioneering the Future

As the automotive industry embraces electric and autonomous vehicles, HCL is investing in next-generation technologies to address these emerging challenges. The company’s R&D efforts are focused on developing:

- Lightweight Brake Linings: To enhance fuel efficiency and reduce vehicle weight.

- Regenerative Brake Compatibility: Solutions optimized for hybrid and electric drivetrains.

- AI-Driven Design: Leveraging artificial intelligence to refine product designs and predict performance trends.

With a clear vision and strong commitment to innovation, Hindustan Composites aims to remain a leader in the friction industry, delivering solutions that drive safety, performance, and sustainability in the automotive, railway and industrial sector.