HORIBA Automotive Test Systems, a leading supplier in the field of engine test systems, driveline test systems; brake test systems, wind tunnel balances and emissions test systems, is aiming to set a benchmark in its Mechatronics (MCT) division by offering products which are world class but at a local cost. The Japanese manufacturer of precision instruments for measurement and analysis, which makes instruments that measure and analyze automobile exhaust gas (roughly 80 per cent share of the world market), has taken baby steps in the MCT space by locally producing dynamometers here.

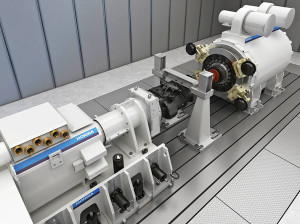

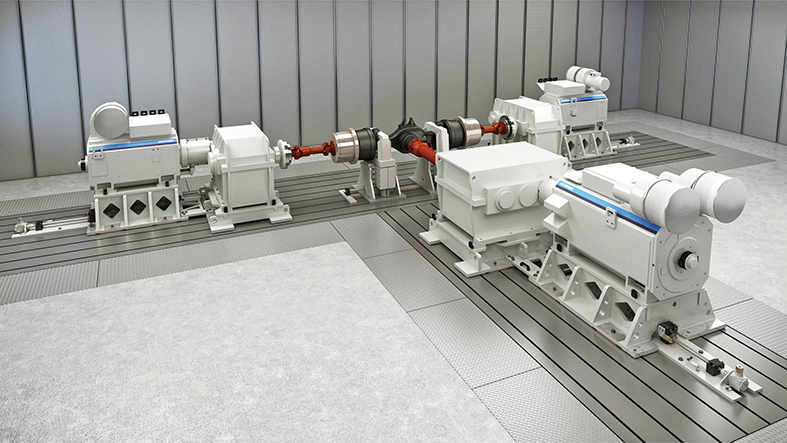

It is to be mentioned that a dynamometer or “dyno” for short is a device for measuring force, moment of force (torque) or power. For example, the power produced by an engine, motor or other rotating prime mover can be calculated by simultaneously measuring torque and rotational speed (rpm).

In an exclusive interaction with MOTORINDIA, Mr. Kai Künne, Technical Advisor, Automotive Test Systems Division, HORIBA India Pvt. Ltd., said: “We have been the market leaders for analysers for more than 50 years worldwide. We would like to be the market leader for the MCT division in India as well by locally making the components. There are some modules which we can produce in India, but some are still imported. We have now started producing these systems locally in phases. Some components we are sourcing locally and some are imported from Europe. We are also assembling them and shipping them to our customers in the domestic market. More than just the world’s leading supplier of emissions testing systems, HORIBA ATS is able to provide total solutions to its customers, with full turnkey capability.”

He added: “Local support is essential for successful business. Unless you commission your own products, you cannot give the right service support – better customised solution to the customers and giving the local service support. Our objective will be to act much faster, have spare parts available, and give the best performance, uptime, among other things.”

Even though HORIBA is present in India through distributers since 1985, it made a formal entry in 2007 and is now running a manufacturing facility in Pune. It may be recalled that it was earlier operating under the company name Schenck in India for the MCT business. But eventually, this particular automotive business segment was taken over by HORIBA in 2005. When HORIBA started in 2005 globally, its portfolio expanded by taking over Schenk, DTS division.

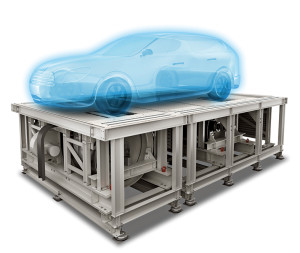

HORIBA ATS, contributing roughly 44 per cent to the entire group, serves manufacturers and suppliers in every industry that utilizes internal combustion and turbine engines, comprising automotive, heavy-duty on/off-road, lawn and garden, marine, aerospace, locomotive, and recreational and utility vehicles. Some of the products sold by the company are analytical emission systems, on-board emission systems, portable emission systems, dilution / sampling systems under the EMS division, and engine test systems, driveline test systems, vehicle test systems, brake test systems, and wind tunnel balances under the MCT division.

Even though emission analysers would continue to be imported, the Dyno systems will be heavily localised to take on other existing players in the market. To promote its products, the company is also planning to participate in SIAT- 2015 and Testing Expo’16.

Mr. Künne added, “We just started our manufacturing operations last year, and we are planning for five engine test systems per year. We have already supplied our transient dynamo-meter engine test systems to our customers. We are looking for full-scale manufacturing at Pune and directly dispatch to our customers instead of importing a CBU from Germany.”

Talking about future potentialities, he said: “The products that we are manufacturing in Japan and Germany were getting imported and sold in India. The second phase began by making the products locally to support our customers for their specific requirements. We are slowly ramping up the level of localisation of our product lines until we can supply the entire systems. We are also streamlining our service network. Furthermore, to cash in on the Make-in-India initiative, our next phase will involve exporting products from India to Brazil, South Africa, Thailand, Indonesia, etc.”

Besides catering extensively to the automotive industry, HORIBA ATS serves and cooperates extensively with regulatory agencies, independent test laboratories, etc. Mr. Parikshit Sengupta, Deputy Manager, Business Development, HORIBA India Pvt. Ltd., shared: “We are catering to most of the four-wheeler manufacturers for their production and R&D applications. Some of our major clients are Tata Motors, Maruti Suzuki, Ashok Leyland, Mahindra & Mahindra, Force Motors, etc. We are also serving Government certification agencies like iCAT, ARAI, VRDE & NATRIP, etc. We are already working in close co-ordination with global auto component firms like Denso, Bosch, Delphi, Sud-Chemie, and BASF. In the future, we will be looking to actively work with Cummins, Daimler, MAN Trucks, etc.” The company has delivered 200 emission systems in India.

Talking about its future course of action, the Deustchmann observed: “Our next big focus will be developing in-house R&D capabilities. It’s in the planning stage and would be a logical progression. It will mainly into application engineering. Some customisation (of products) will also happen. Besides, we are exploring additional domains like E-mobility which is at a very nascent stage.”

The HORIBA Group of worldwide companies provides an extensive array of instruments and systems for applications ranging from automotive R&D, process and environmental monitoring, in-vitro medical diagnostics, scientific & semiconductor manufacturing and meteorology, to a broad range of scientific R&D and QC measurements. It has been widely believed that the proven quality and trustworthy performance have generated widespread confidence in the HORIBA Brand. HORIBA is one of the top 25 analytical and life sciences instrumentation companies in the world.

Spelling out the long-term vision of the company, Mr. Künne said: “The value of both the segments that we are operating in is worth more than Rs. 250 crores in India. This will go up manifold. By 2020 we aim to achieve a 51 per cent share in the MCT market.”