The Indian trailer industry is one that has much scope for progress which is yet to be explored. Given the latest technology that is available within and outside the country, the segment has the potential to grow faster than the current pace it is following. Challenges are aplenty and range from slow uptake on advanced safety technologies to road infrastructure that is still getting built. An array of such issues and more were discussed at length by the experts in the field under the webinar topic ‘Maximizing Returns on Trailer Fleets’ hosted recently by MOTORINDIA. Sarada Vishnubhatla reports

Gracing the panel were Rajiv Batra, CEO, Tata International DLT, V Ramanathan, Head – OE Sales & Marketing, ZF Group – Commercial Vehicle Control Systems, WABCO India, and Christiaan Verschueren, VP, Trailer Systems, ZF Group – Commercial Vehicle Control Systems, WABCO Europe BVBA. As a co-panelist and moderator, G S Pradeep, MD, JOST India shared concerns on tractor trailer homologation and its slow uptake besides talking about a few drawbacks that the industry may be ridding itself of and receiving a new shot at progress.

Excerpts from the webinar:

Rajiv Batra, CEO, Tata International DLT

Bringing the Change – AIS 113 Code

When the AIS 113 was announced in 2016, the cost difference was quite high between vehicles that qualified the code and those which did not. In the last 4 years, industry has worked hard, especially the trailer manufacturers and the parts supplier, because of the indigenization so the cost has reduced to almost 50%. I feel that the stakeholders need not wait for the government to enforce safety norms, but we should be proactive about it. I believe that OEMs must play the elder brother role. And they should not focus only on the sale of their product but they should insist that it should be paired with the right trailer that qualifies the ARAI norms.

Technology Uptake

Significant work is going on in technological advancement with our key suppliers in axle, suspension, electricals, tyres, and steel.

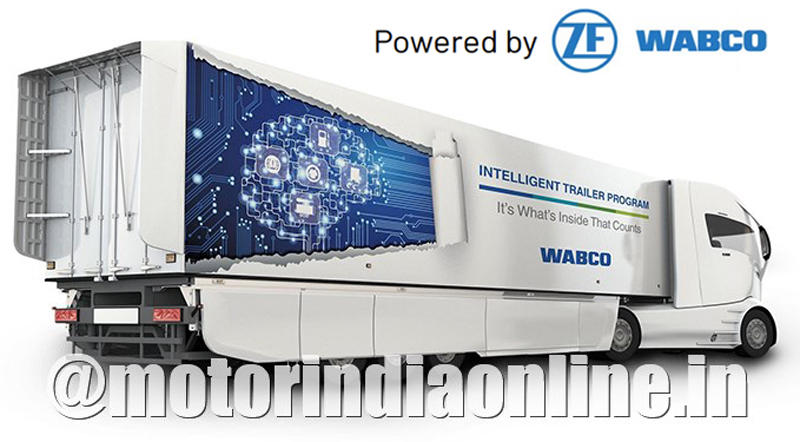

In 2018, we had developed the first intelligent trailer along with WABCO and there are 40 loaded technologies. Post that, we produced 2 more. I feel in the trailer industry steel is one parameter which is getting ignoring. We have tied-up with a company who make special strength of steel and now we are developing trailers using it and the fleet owner can gain 25-30% weight reduction with the special steel.

Making Trailers Safe, Efficient & Profitable

In the Indian context, road accidents are frequently fatal especially when tractor trailers are involved. This is one of the major concerns of the industry. Both truck and trailer OEMs should understand that both are integral to the industry. The trailer is the better half of the tractor and tractor performance depends on trailer quality. What the truck OEMs and some fleet owners must understand is that the total vehicle performance and safety is important rather than that of only the prime mover because many trailer design factors can affect how the vehicle moves and its performance and have an impact on fuel efficiency and tyre life. Poor alignment of the trailer braking system will impact tyre life and we know that in the transport industry, tyre life and fuel are the lifelines.

The trailer manufactures are working diligently with the fleet owners to improve their profitability and efficiency. Also, the government has taken good initiatives in the past to improve both. Technology wise with the help of the part suppliers, our fleet owners can recover their losses and come up with efficient and profitable business.

GST reduction from 28% to 18% in the trailer segment is one of the biggest advantages that has been bestowed by the government especially for the small trailer buyer. In mid-August 2018, axle load was increased which again was a good initiative by the government in favor of the fleet owners by which they have increased their efficiency by an average of 18 to 20%.

—-

V Ramanathan, Head – OE Sales & Marketing, ZF Group-Commercial Vehicle Control Systems, WABCO India

Future & Challenges

In the last five years, the trailer industry grew by almost 10-15% a year. During COVID pandemic, the market came down by 50%. But in the next five years, we can anticipate a good growth percentage of 15% CAGR. Yet, the trailer industry in India is not as mature as it is in countries like China, Europe and the US. In the developed countries, we see the tractor trailer combination form almost 40% of the medium and the heavy commercial vehicle industry. But in India, in 2017-18, the maximum tractor trailer combination seen was 7-8%. But now it has come down to 3-4%.

It is dismal in India because of infrastructure as one of the many challenges. Not many roads are wide enough to allow maneuverability of the tractor trailer combination, and many cities do not allow tractor trailers to enter the city limits in certain periods of time. The fleets also do not fully leverage the flexibility or the interchangeability of the tractor trailer model. And another challenge is that not many skilled drivers are available in the industry to run the tractor trailer combination.

As the government is taking steps both in the terms of infrastructure as well as the legislation, the conditions are favorable for the tractor trailer industry in the long run. Now that the government has clarified that the tractors and trailers can be registered separately, it will allow the flexibility for the trailer fleets to leverage the profitability and also the hub and spoke logistic model will evolve further which will be favorable for the trailer industry as a whole.

Future will see the interchangeability of a tractor trailer combination being fully leveraged. Some green shoots can already be seen in the market where a few fleets are going for independent registration of the trailers. If the road transportation sector wishes to compete with the railway freight corridor, then they must go for this tractor trailer combination.

Making Trailers Safe, Efficient & Profitable

There are three parameters – safety, efficiency and connectivity. In terms of safety, even though the legislation has been in place since 2017 yet only 20% of the trailers are compliant with it. So, all the stakeholders are responsible and even though the CMVR 125 D specifies the standards for the trailer body, the braking system besides the trailer ABS system, the implementation is weak in many states across India. The number of road accidents is high in India and the primary cause is frontal collision and also 2% of the accidents occur while reversing.

Efficiency wise today the tractor trailer utilization is only 33% compared to the global standards, and the government has allowed a single tractor to multiple trailers, but the fleets are not leveraging this flexibility and in terms of maintenance, the tractor is given more importance than the trailer.

—-

Christiaan Verschueren, VP – Trailer Systems, ZF Group-Commercial Vehicle Control Systems, WABCO Europe BVBA

Technological Impact on Indian Trailer Market

Technology wise, the ABS was mandated in India in 2017. For us at WABCO, it was the penultimate spot on the map where the ABS mandate came in before Brazil. Heavy combinations like tractor trailer combinations must be ensured that they are safe before plying on the road.

And loss of control is not just down to the skills of the driver, it is the road conditions too which can make even a skilled driver try hard to keep the vehicle safe on the road. Therefore, one of the best ways to ensure safety is to enforce ABS and to go on to the next step which is automatic functionality.

Global Trailer Market

Though a bit unrecognized as an industry, many evolutions are happening in the last few years globally starting from Europe. Trailers are developing into highly specialized vehicles that are custom-made to carry goods in a safe and reliable way.

There are two clusters of markets – big giant markets of North America, Europe, and APEC where roughly 300,000 trailers are built per year in each of these areas which highlights the importance of the tractor trailer combination. Compare that to India, Middle East, Africa and South America where the number of trailers is much lower.

The European market is entirely on electronic braking systems and a little bit on ABS brakes and North America is now starting on it too.

Globally, the entire tractor trailer market is growing and the ratio between the number of trailers per tractor is increasing too which reflects efficiency and indicates to more need for transportation.

Every single market is evolving the same way – going from basic airbrake system with a notion to have more safety, then comes ABS. Air suspension is important for safety of the person and the cargo. If variable cargo is loaded on the trailer, it needs to arrive without damages. If overloading is not any more a problem, then air suspension is a good system to protect the cargo. Climbing the technology ladder, we can find the order as the electronic braking system or the ADAS brake. These are fundamentals for the safety of the trailer. ADAS brake is more reliable a system than the traditional drum break. And the good news is that every single market is climbing this technology ladder.

Technology Uptake

The foundation of any trailer OEM is to have a solid braking and suspension connectivity, making sure the vehicle is safe in all conditions. The first point of focus is on the braking systems – ABS and EBS. Bur EBS is an active system unlike ABS. If the trail is about to tip over, then the EBS, on its own without any intervention of the driver or the prime mover, will immediately pull on the brakes keeping the vehicle safe. This is why it is highly popular with transportation of dangerous goods and fuel. With EBS, the total cost of ownership is earned back immediately because there is no downtime or accidents.

WABCO will be soon launching a new EBS with a completely new algorithm for the leaf suspended trailers which is still the majority of the Indian market.

In India, intelligent trailer program was introduced in 2018 and since then a good number of fleets have tried it out to really see how the trailer can actually make the entire fleet operation safer and more efficient, save fuel and provide more driver comfort.

The advanced safety products, which can avoid fatal accidents while reversing, includes tail guard where sensors are installed at the back of the trailer. These sensors see what is behind the trailer and alert the driver whether or not to reverse, wherein the trailer will stop by itself without any signal from the driver. It is an advanced ADAS system on a trailer just for reversing. In Europe, it is almost a standard application in trailers and the US has started picking it up.

—-

G S Pradeep, MD, JOST India

Bringing the Change – AIS 113 Code

The Trailer Type Approval Code (AIS 113) and the consequential component approval code were both announced in the year 2016. The next logical step is to promote the benefits of the implementation of the interchangeability of the tractor and the trailer. There are trailer building hubs that are getting trailers homologated. I believe that the trailer builders now understand the importance of this code, and its benefits. Going forward, the interchangeability can bring benefits to them.

The drawback is that despite the support from the government, the tractor trailer domain itself has not grown into its size and form which can benefit the fleet owners. Around the world, tractor trailers form more than 75% of the market but in India, it is a paltry 12% during low market situation and about 18% when at its peak. COVID-19 too has added to the woes.

Technology Uptake

We are talking about steering systems for the trailers coupled with air suspensions which the end customers can benefit from in terms of reduced tyre wear as drag will be eliminated improving upon the fuel economy. We are also talking about completely autonomic coupling and decoupling systems. Another segment is swap body chassis which is still not popular in India.

Wrap Up

In a nutshell, the panelists agree that the Indian trailer industry is poised for good growth going forward while aggressively adopting latest safety technologies. And that is how the industry can maximize on the returns, sooner than later!