Three out of eight MPIF Awards bagged

The Bangalore-based Indo-MIM, a global leader in the field of metal injection molding (MIM), supplies precision-engineered products to customers in more than 30 countries. The company plans an investment of Rs. 350 crores in Karnataka and expects to raise it to a level of Rs. 1,200 crores while adding 1,000 more employees over the next three-five years. The company which registered a turnover of Rs. 500 crores in fiscal 2013 has offices in the US, Europe and China.

Some of Indo-MIM’s high-profile clients include Fortune 500 companies all over the world spread across more than 30 countries covering several industry segments. MIM is an emerging manufacturing technology utilized to produce metal components of complex geometries in large volumes. Indo-MIM which has the distinction of utilising the services of Indian engineers to enhance the US technology employs about 300 engineers in India.

Said Dr. Krishna Chivukula, Chairman Indo-MIM: “We are growing year on year at an approximate rate of 30% and expect to do a turnover of Rs. 1200 crores in 3-5 years. During 2014 fiscal year and ensuing five years, Indo-MIM plans to aggressively increase its capacity in Bangalore India and in select countries overseas, thereby ensuring its pre-eminence in the MIM industry”.

Established in 1998, the Bangalore-based Indo-MIM has since expanded its facilities into the largest installed MIM capacity in the world. The employee strength at the Bangalore facility is about 2,000. Besides MIM, the company does aerospace precision machining and surface treatments. Its plant at Tirupati in Andhra Pradesh specialises in production and export of investment castings (IC) for the automotive sector.

The MIM industry sales at the global level at about $1 billion are growing at a rate of 10-15 per cent per year. Indo-MIM’s competitors are primarily located in the US, Europe and China. There are about 15-20 companies in the world with annual turnover of $25-35 million and 50-odd companies with a turnover of $1-10 million.

Global Awards

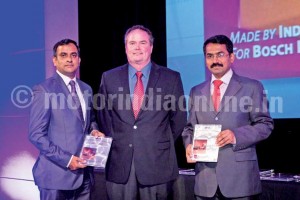

Indo-MIM received three of the eight Metal Powder Industry Federation (MPIF) PM Design Excellence Awards at the recently concluded Powder Metallurgy Conference PM- 2013 in Chicago. This industry body evaluates companies across the US, Japan, France, Italy, Spain, Germany, China and India.

In the automotive engine design category, Indo-US MIM received the Grand Prize for the “Threaded Port, Metal Support Ring and Sensing element”. The MIM Threaded Port, Metal Support Ring and Sensing element helps the customer save over 50 per cent of the cost of fabrication using alternate technologies.

The company also received a Grand Prize in the Consumer Segment for a Tool holder assembly consisting of two MIM parts – a tool holder and a grip-spring tensioning part that goes into a woodworking tool for fine detail carving. The MIM design contributes to a LEAN operation for the customer by substantially reducing lead-time through the elimination of many processing steps.

In the automotive segment, Indo-MIM received an Award of Distinction for a fuel-control gear segment that goes into a device that regulates the entry of fuel into the engine. Converted from a machined part, the gear segment is fabricated via MIM from low alloy steel at a saving of 80 per cent over the previous method. The fabricator delivers nearly three million pieces annually to the customers.