The Indian mechanised cleaning industry has truly come of age. Unlike manual sweepers or cleaners who were relied on nearly two decades back, there has been an unprecedented acceptance of mechanised cleaning solutions, thanks to revolutionary products rolled out by companies like Inventa Cleantec Pvt. Ltd. (ICPL), a leading homegrown brand catering to both buses and trucks as well as passenger vehicles and other industrial applications.

The company, which has grown from strength to strength, has now become a leading manufacturer and supplier of affordable cleaning equipment for automobile and other industries. Its product range covers dry and wet vacuum cleaners, industrial vacuum cleaners, etc. Its cleaning equipment is installed countrywide, in government, semi-govt enterprises and other public sector units and even automobile garages. Most of its products are made in collaboration with a renowned Italian firm Annovi Reverberi. Incidentally, the company is exporting mechanical floor sweepers to only Italy.

“It was a concept selling in the 90s. But now it is more of a need-of-the-hour than a concept selling. The industry which we are in is truly evolving because of the need for seamless cleaning and the aesthetics involved in it. When you talk about the automobile industry in particular, with the number of vehicles increasing and the kind of investments the OEMs are making in the vehicles, the demand patterns of end users for cleaning are changing rapidly,” revealed by Mr. Arun Thapar, Managing Director and CEO, Inventa Cleantec.

It is to be mentioned that Mr. Arun Thapar, a mechanical engineer, floated ICPL in 1990. This was after his stints with various automobile industry-affiliated industries like tyres, auto components, etc.

It is to be mentioned that Mr. Arun Thapar, a mechanical engineer, floated ICPL in 1990. This was after his stints with various automobile industry-affiliated industries like tyres, auto components, etc.

The business started flourishing when Mr. Karan Thapar, the founder’s son, a mechanical engineer graduate from University of Singapore, stepped into the business in 2009. With the second generation entrepreneur at the helm of affairs, the company streamlined its operations that involved strategies like extension of product lines, diversification into new industries, technical upgradation of products and participation in key exhibitions like Auto Show’14.

The young and dynamic, Mr. Karan Thapar observed: “In 1990, we started a unique concept called ‘Hi-pressure Water-Jetting’. The idea was to use water at high-pressure for cleaning purposes. Over a period of time, we realised that there was a need for mechanised cleaning solutions in the Indian market. To cater to that segment, we started a range of commercial cleaning equipment. This was for the maintenance of large campuses like hospitals, hotels, malls, railway stations, metro stations, airports, etc.”

He affirmed that with a stable government at the Centre now, the company expects a massive resurgence of the mechanised cleaning and automotive industries. A minimum 20 per cent growth in both the industries is certain.

Bus industry, a cash cow

Celebrating its Silver Jubilee next year, ICPL is looking to widen its revenue streams in the bus cleaning systems market. Mr. Karan said: “I would say the bus segment is pretty big and it contributes 20 per cent to our overall business. We have three key product lines catering to the bus segment, i.e., Terra priced at around Rs. 14 lakhs, Aqua priced at around Rs. 7 lakhs, and Nova priced at around Rs. 26 lakhs. All are locally made. We have a dedicated assembly line for buses.”

Celebrating its Silver Jubilee next year, ICPL is looking to widen its revenue streams in the bus cleaning systems market. Mr. Karan said: “I would say the bus segment is pretty big and it contributes 20 per cent to our overall business. We have three key product lines catering to the bus segment, i.e., Terra priced at around Rs. 14 lakhs, Aqua priced at around Rs. 7 lakhs, and Nova priced at around Rs. 26 lakhs. All are locally made. We have a dedicated assembly line for buses.”

Throwing further light on the company clientele, he said: “We cater to the cluster bus segment run by the Delhi Transport Segment. These are privately-owned and operated under a government entity called the Delhi Integrated Mass Transport System (DIMTS). We have also supplied a handful of Aqua and Terra models to AB Grain Spirits, which has a fleet of 500 buses. We cater to Ashok Leyland, which maintains DTC buses. We supply our products to various bus depots. Then there are State transport corporations which are under the guidelines of the All India State Road Transport Union (ASRTU). These are mainly for interior and exterior cleaning. Besides, we have joined hands with transport undertakings like the Gujarat State Road Transport Corporation (GSRTC) and the Rajasthan State Road Transport Corporation (RSRTC). We should be inking a deal with the Kerala State Road Transport Corporation (KSRTC) as well as the Andhra Pradesh State Road Transport Corporation (APSRTC). Talks are on with the Himachal Road Transport Corporation (HRTC).”

In the future course of action, the Noida-based firm is also keen to serve OEMs like Tata Motors, Ashok Leyland, AMW, Bharat Benz, etc., directly, in addition to fleet operators and State transport undertakings.

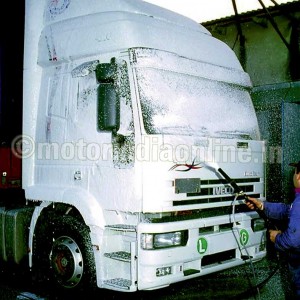

After gaining a strategic foothold in the bus segment, ICPL has diversified into the truck segments. Mr. Karan stated: “It was a logical progression for us to serve the load carrier segment. However, catering to this segment is a different ballgame as the product itself has a different body profile. As a first step, we are in active talks with Hindustan Zinc for their own fleet of trucks. We have already installed an equipment at the army base camp at Race Course in New Delhi meant for multiple types of defence vehicles. Our product caters to a broad spectrum of vehicles like loaders, buses, dumpers and passenger carrier trucks. We have given a programming cycle for all sorts of vehicles. Going forward, we are planning to serve a number of truck operators. We are also thinking about diversifying further into the construction equipment segment.”

After gaining a strategic foothold in the bus segment, ICPL has diversified into the truck segments. Mr. Karan stated: “It was a logical progression for us to serve the load carrier segment. However, catering to this segment is a different ballgame as the product itself has a different body profile. As a first step, we are in active talks with Hindustan Zinc for their own fleet of trucks. We have already installed an equipment at the army base camp at Race Course in New Delhi meant for multiple types of defence vehicles. Our product caters to a broad spectrum of vehicles like loaders, buses, dumpers and passenger carrier trucks. We have given a programming cycle for all sorts of vehicles. Going forward, we are planning to serve a number of truck operators. We are also thinking about diversifying further into the construction equipment segment.”

Automotive exhibitions

ICPL has been participating in numerous auto shows like Bus and Utility Vehicle Show’13 and Auto Expo’14. “Auto Expo’14 at Pragati Maidan was much better organised than in 2012. We found that the footfalls and enquiries were much more genuine than the 2012 Auto Expo. Only those people who were interested in our products were making a walk-in. That was a positive change in the event. We will again participate in the event, in 2016.”

Even though most of the company products are made locally, some others like vacuum sweepers, floor polishers, pressure jets and cleaning agents are imported from Italy. At present, ICPL is running two facilities of approximately 20,000 sq.ft. of production space capable of manufacturing eight automatic car washes and six automatic bus washes a month. Welding, cutting, polishing, thermoforming and hot painting (oven powder coating) are done at these plants. Depending on the size of the order, a nominal production time of 4-8 weeks is followed. Once the site is ready at the clients’ end, the company team takes a week to a maximum of 10 days for installation, testing and training.

As far as its in-house R&D centre is concerned, ICPL has three people on its rolls with one stationed as the Head 3D CAD-CAM designer and one as the workshop executive. The design and development process involves four basic steps, namely, inception, 3D design, prototyping and correction, until the company has a production-based model. As far as its distribution network is concerned, there are three company-owned offices and 35 dealers present in 28 cities. Going forward, Inventa is planning a JV with a company to market and service its products through its own offices in various cities.

As far as its in-house R&D centre is concerned, ICPL has three people on its rolls with one stationed as the Head 3D CAD-CAM designer and one as the workshop executive. The design and development process involves four basic steps, namely, inception, 3D design, prototyping and correction, until the company has a production-based model. As far as its distribution network is concerned, there are three company-owned offices and 35 dealers present in 28 cities. Going forward, Inventa is planning a JV with a company to market and service its products through its own offices in various cities.

ICPL maintains that availability of skilled manpower is a big problem which needs to be addressed forthwith. “Even though we have the infrastructure in place, it is directionless. ITI students should be trained in cleaning the equipment too,” said Mr. Arun Thapar.

Talking about the emerging trends, he remarked: “There are some operators who would like to imitate international transport fleet models. People are paying for cleaner and are getting better buses. Moreover, hi-end trucks by MAN and Scania need proper cleaning and maintenance.”

ICPL clocked Rs. 11 crores during the last financial year, of which the bus and truck segments accounted for Rs. 1.5 crores and Rs. 0.5 crore respectively. It is expecting to earn over Rs. 13 crores during FY 2014-15 and is anticipating a 20 per cent growth on a y-o-y basis in the next few fiscals.

“We want to give an indigenised solution for the problem as related to the automotive industry and give a very price-worthy efficient solution for all the possibilities. In addition, we also want to spread across India through the automatic car, bus and truck washing systems. We would also like to supply our products to metro transport systems I would like to see one car or bus washing system in every 2 sq. km,” signed off Mr. Karan Thapar.