At the IAA Commercial Vehicles 2014 from 25 September to 2 October 2014 in Hannover, JOST Group will be presenting innovations and further developments in addition to its diverse product programme with components and systems for truck & trailer. This includes the premier of the new, ultra-light JSK 34 fifth wheel coupling. Other highlights of the presentation include JOST safety systems, including the series-production-ready, fully automated KKS II coupling system and the JOST SDR roof diffuser which reduces the air turbulences at the rear of the vehicles which in turn reduces fuel consumption. The JOST Group will be presenting hydraulic systems by Edbro for the first time at an IAA trade show. Edbro has been part of JOST Group since November 2012 and will present the newly developed CS 17/18 Ultra series – the lightest front lifting cylinder in the class of tipping weights up to 60 tonnes. JOST brands including ROCKINGER with its towing hitches and TRIDEC with its trailer axle steering systems and single wheel suspensions will present tried-and-tested products such as the RO*40 E towing hitch as well as current developments such as the DL-S single wheel suspension for low-loaders at the JOST Group stand in Hall 26, Stand D34.

JOST

New ultra-light JSK 34 fifth wheel coupling

JOST will be presenting the new, ultra-light JSK 34 fifth wheel coupling at the IAA Commercial Vehicles 2014. The cast coupling is designed for two-inch king pins and a technical imposed load of 16 tonnes and is ideally suited for all weight-sensitive transports, such as tanker and silo transports.

However, the new fifth wheel coupling is not only characterised by the reduced weight. With the JSK 34, JOST will present for the first time a new, particularly safe unlocking with one-handed operation of the security latch. Unlocking is easy and ensures an excellent visibility of the locking position at all times. Thus, the new one-handed operation of the security latch provides safety during coupling and decoupling.

JOST has equipped the JSK 34 with a newly developed hybrid bearing to increase driving comfort and service life while reducing the dynamic load on the vehicle’s frame at the same time. Here, a rubber shock absorber encompasses the central plastic bearing block. This way, the hybrid bearing combines the robustness and shock absorbing effect of a rubber bearing with the frame-friendly properties of a plastic bearing.

The JSK 34 can be equipped with the integrated JOST LubeTronic central lubrication system upon request. In addition, it is available with sensors, pneumatic unlocking as the SKS sensor coupling system, as well as in conjunction with the fully-automatic KKS coupling system.

Series production of fully automated KKS II coupling system begins

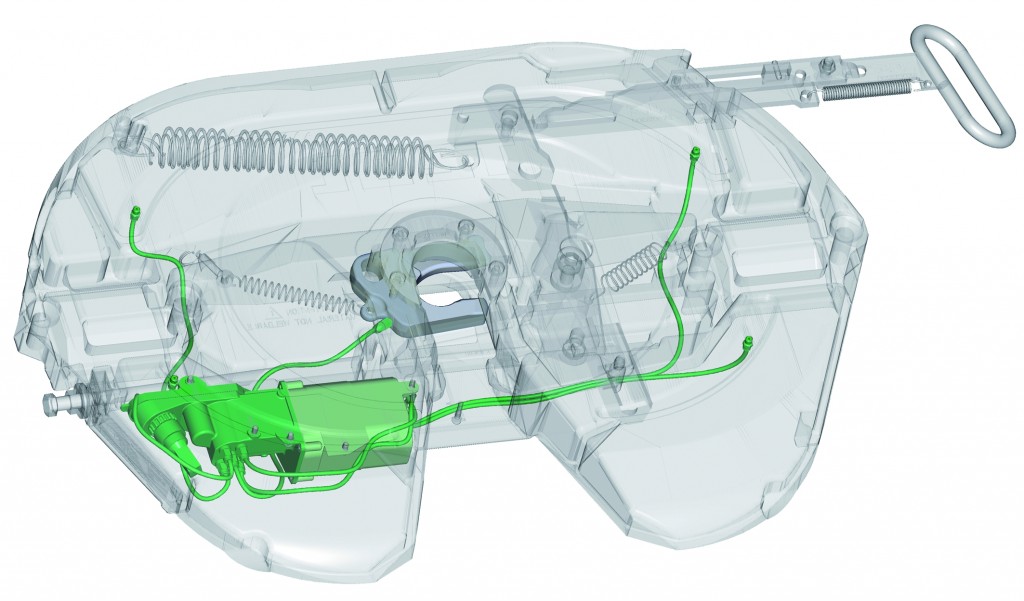

JOST is the first manufacturer to now offer a fully-automated coupling system for tractors, the KKS II Comfort Coupling System, that complies with all legal requirements and which is fully compatible with vehicles without KKS II. The new KKS II Comfort Coupling System from JOST is a fully automatic driver assistance system that controls all functions of the coupling and decoupling process that have previously been performed manually. This also includes the first ever automated interface for pneumatic and electric connections. Operation and remote display are located in the driver cabin for all functions. The advantages of KKS II are obvious: increased safety, easier handling and less time and effort.

KKS II is based on a sensor-monitored JOST fifth wheel coupling with automatic locking and a pneumatic unlocking function. When coupling the truck and trailer, the driver can see at the display if the tractor’s fifth wheel plate and the trailer’s king pins are set to the right height for one another and whether the fifth wheel coupling has been completely closed. The fifth wheel coupling can be unlocked easily and safely during decoupling from the driver’s seat with the push of a button. This is all done pneumatically.

An additional core of the fully automatic coupling system is the interface for compressed air and electricity (2x pneumatic brakes, 7x EBS electricity, 15x trailer lights). In addition, there are 8 contacts provided including for a data bus and power supply possibilities for future applications. At the trailer the outlet is housed below the fifth wheel coupling in the area of the wedge and is protected against dirt and splash water by an automatically opening flap. The matching plug is on the trailer, directly behind the king pin and is located in a housing. During decoupling, this housing automatically opens from the engagement pressure from the fifth wheel coupling. During the coupling process, the electropneumatic power lines are thus automatically connected. Thus, it is not necessary to connect or disconnect spiral cables. The driver no longer has to force himself into the poorly accessible area between the cabin and the front of the trailer. A control display in the driver cabin shows the status of the connection. Thanks to the automatic connection, there is also no more damage or failures due to ripped out or defective power lines. Downward compatibility with conventional electric and pneumatic connections represents another particular advantage of this automated interface developed by JOST. Tractors and trailers can thus be joined together with and without KKS, as you like.

As a third component, the electrically operated landing gear for the trailer completes the new KKS II driver assistance system. This too can be operated from the driver cabin with the mere press of a button.

All functions of the KKS can also be operated manually. This ensures that it is always possible to combine KKS tractors with conventional trailers or to combine conventional tractors with KKS trailers. It is likewise possible to use KKS II in trailers with axle steering systems. KKS II is currently only intended for installation in new vehicles due to its complexity and required integration within the vehicle.

JOST SKS for more safety during coupling and decoupling

Other safety systems offered by JOST for truck & trailer will also be the focus of the JOST presentation at the IAA Commercial Vehicles 2014. Amongst others, these include the sensor-controlled lock checking system Flashtronic and the SKS sensor coupling system. JOST fifth wheel couplings equipped with SKS have sensors to show the driver in his cab that the fifth wheel coupling has locked securely. The driver also has the option of unlocking the coupling pneumatically via a remote control, even when the tractor-trailer is twisted or in unfavourable space conditions. This means that SKS does not just make coupling and decoupling easier and safer, the system also saves the driver from getting out of the cab unnecessarily, thus further improving safety at work.

Never lubricate by hand again thanks to LubeTronic 5Point

The JOST LubeTronic 5Point is an integrated lubrication system for standard fifth wheel couplings from the JSK 37, 38 and 42 series that provides grease not only to the lock jaw but also to the fifth wheel coupling plate. An electronic control device supplies the grease in precise doses at regular intervals. This ensures that there is always enough, but not too much, grease on the fifth wheel plate and lockjaw. That saves grease and is environmentally friendly. The lubricant in the lubrication cartridge on the fifth wheel coupling will last for around twelve months. An easy-to-read LED display shows the level of the grease reserves at all times.

The JOST LubeTronic 5Point is an integrated lubrication system for standard fifth wheel couplings from the JSK 37, 38 and 42 series that provides grease not only to the lock jaw but also to the fifth wheel coupling plate. An electronic control device supplies the grease in precise doses at regular intervals. This ensures that there is always enough, but not too much, grease on the fifth wheel plate and lockjaw. That saves grease and is environmentally friendly. The lubricant in the lubrication cartridge on the fifth wheel coupling will last for around twelve months. An easy-to-read LED display shows the level of the grease reserves at all times.

For the annual refilling of the LubeTronic 5Point, JOST provides the fully synthetic JOST high-performance lubricant both in cartridges for one-off filling and in a 30kg barrel, sufficient for 35 fillings. The special grease is temperature-resistant, adheres particularly well to all metal surfaces and is therefore ideally suited to the manual lubrication of all fifth wheel couplings. JOST specifies the use of the JOST high performance lubricant for refilling the LubeTronic 5Point.

Pro Tech Slider: JOST’s safe slider

With sliders, fifth wheel couplings can be easily and quickly moved on the vehicle frame, thus allowing the position of the fifth wheel coupling to be adjusted for different trailers. Sliders are mainly used in Great Britain and markets outside of Europe. Pro Tech Slider is a slider for standard fifth wheel couplings. At IAA 2014, JOST will exhibit the Pro Tech Slider in connection with a fifth wheel coupling in pressed steel design:

the JSK 36.

The Pro Tech Slider offers an enormous weight advantage of up to 55 kilograms in comparison to conventional sliders. Furthermore, the Pro Tech Slider is especially safe thanks to its self-locking mechanism. It is impossible for the blocking pieces to come loose, no matter the circumstances, which reliably prevents inadvertent sliding. The profile of the slide rails is also surrounded on both sides, which significantly increases the safety and stability. The Pro Tech Slider is available in both an inboard version, where it is screwed directly on to the side of the frame, and a classic outboard version, where it is screwed on vertically.

JOST SDR helps saving fuel

JOST will present one of the company’s product innovations – the highly-efficient JOST SDR air flow system. The SDR roof diffuser is an aerodynamic airflow system which reduces the decelerating air turbulences at the rear of the vehicle. This effect is reflected by fuel savings of up to four percent, depending on such factors as driving speed, tyres or route profile. Comprehensive field testing by vehicle manufacturers and transport companies confirm this. The patented SDR roof diffuser from JOST directs the air flowing over the roof to the low-pressure zone behind the rear of the vehicle. This creates less air turbulence and thus lower air resistance. Thanks to the resulting fuel savings, acquisition costs of the SDR roof diffuser pay for themselves after only a few months.

And as it reduces consumption, the SDR roof diffuser also decreases CO2 emissions, thus protecting the environment. Additional benefits of JOST’s SDR roof diffuser resulting from the low air turbulence behind the vehicle are most noticeable during bad weather: less spray mist develops behind the vehicle on wet roads. The rear of the vehicle remains cleaner and the view for following vehicles is improved.

The JOST SDR roof diffuser can be installed very simply on both box and tarpaulin bodies. The SDR is easy to install on top of the rear end of a truck body, trailer or semi-trailer – of course retroactive installation is also possible. After installation, the SDR roof diffuser is completely maintenance-free. The SDR is now part of JOST’s range of products and can be obtained through the JOST Group wide marketing network.

ROCKINGER

Multi-purpose safety-towing hitches

The traditional ROCKINGER brand offers commercial vehicle operators a wide range of towing hitches for various different mounting points and for every type of use. Security is also given top priority with the towing hitches: the drawbar turn angle warning system specially developed by ROCKINGER, with its display in the driver’s cabin, offers reliable protection from shunting damage to couplings, drawbars and the rear of the vehicle. RO*40 E, the newest coupling for highest demands, will be on display at the JOST stand in Hall 26. The slack-free coupling for 40 millimetre drawbar eyes has an intrinsic weight of 30 to 33 kilograms, which makes it especially lightweight. The proven ROCKINGER release level technology ensures that the bolt is triggered safely and precisely; the coupling is always ready to engage and the coupling and decoupling even with difficult drawbar eye angles is handled easily and trouble-free. The RO*40 E can also be equipped with a remote control as well as a dual-sensory-controlled display. The display in the driver’s cabin shows proper locking.

An additional highlight presented by ROCKINGER at the IAA Commercial Vehicles 2014 will be the unique RO*430 comfort coupling. This towing hitch for 40 millimetre drawbar eyes is not only slack-free, it is also equipped with a rubber suspension and hydraulic shock absorbing which ensure that possible impact stress between the truck and trailer is absorbed by the coupling. The RO*430 thus ensures the highest driving comfort and is therefore ideally suited for use as a standard coupling for articulated omnibuses, such as the ones in use by the Münchner Verkehrsgesellschaft (MVG) public transport corporation. When it comes to installation in bus trains, the RO*430 can be equipped with an electropneumatic remote control as well as sensor technology for monitoring the coupling process and proper locking. This allows the driver to safely and comfortably operate and monitor the towing hitch without having to leave the cabin.

TRIDEC

TRIDEC DL-S: Single wheel suspension for low-loaders

TRIDEC, specialist in trailer axle steering systems and suspensions within JOST Group, will also be presenting a new development at the

IAA Commercial Vehicles Show such as the DL-S single wheel suspension for low-loaders which allows higher capacity, larger installation spaces and improved driving properties. Thanks to the divided suspension, TRIDEC DL-S (Dual Lever Suspension) offers a permissible axle load of up to 12.0 tonnes per axle line. And its low intrinsic weight of only 675 kilograms makes it significantly lighter than comparable systems. The vehicle’s capacity can therefore be much higher than when using non-conventional axles. This also allows vehicle constructions with fewer axles per vehicle while providing greater capacity – a tremendous advantage particularly for multiple-axle low-loaders and extendible trailers.

TRIDEC DL-S uses delta suspension arms which are secured onto the vehicle frame by maintenance-free rubber bearings. Dual effect hydraulic cylinders with covered track rods control the suspension. The large range of travel of 200 millimetres lift and 100 millimetres lower, as well as the integrated stabilisation system provide the DL-S single wheel suspension with excellent driving properties and roll stability. In addition, the hydraulic suspension also provides the option of using a lift axle on one or multiple axles. The compact design and sophisticated construction of the DL-S make – depending on the width of the central frame – steering angles of up to 57 degrees possible. This makes it possible to realise smaller turning circle diameters which allow longer vehicles to comply with the requirements for an authorisation in accordance with § 70 of the StVZO (German Road Traffic Licensing Regulations). The single wheel suspension can also be ideally combined with a TRIDEC steering system, optionally with the TRITRONIC electronic-hydraulic steering with automatic height regulation, manual control, automatic alignment and many other functions. An additional advantage of the compact design of the TRIDEC DL-S is its loading height, which equals a mere 890 millimetres when using 17.5 inch tyres. At the same time, the DL-S also provides a generous installation space of up to 650 millimetres in width between the wheels. This can be used, for example, for large dump trucks or innovative loading ramp systems.

The new TRIDEC DL-S single wheel suspension for low-loaders is impressive not only for its high capacity, great agility and excellent driving properties, but also thanks to its extremely low-maintenance construction: To this end, all bearings on the delta suspension arms and hydraulic cylinders are made of high-quality and low-maintenance materials. The DL-S is service friendly, resulting from the construction utilising an outboard hub and drum. This makes it possible to remove the drums and replace the brake linings without having to open the wheel bearing, preventing damage caused by dirt on the bearing or faulty bearing settings.

HF-E: Hydraulic steering for low-loaders

The HF-E hydraulically controlled trailer axle steering is especially used in low-loaders and semi low-loaders with up to seven steered axles. The steering movements of the pulling vehicle are transmitted to the hydraulic system through a steering wedge that is connected to the fifth wheel coupling; the system then transmits the steering movements to the first steered axle. All other steered axles are then steered by the steering rods from this axle. The HF-E thus achieves steering angles of up to

45 degrees, depending on the model. This allows this innovative steering system to offer optimum manoeuvrability, stability and agility, even in particularly difficult applications. The wear and tear on the tires is also reduced significantly. TRIDEC has made significant improvements to the HF-E, especially in terms of ease of maintenance. There are no longer any lubrication points on the steering units, only on the steering rims. The welded sections have been replaced by cast parts. TRIDEC also delivers each HF-E steering system pre-assembled and ready adjusted. The vehicle manufacturer can simply screw the entire system onto the chassis. When used with the Tritronic electronic remote control, a vehicle equipped with HF-E achieves optimum manoeuvrability in any situation thanks to manual steering.

In addition to hydraulic trailer axle steering, TRIDEC also offers mechanical and electronically controlled steering systems for trailers. Their range of products also includes wheel suspension systems for double-deck and glass-transport trailers as well as hydraulic suspensions and oscillating axles. TRIDEC systems can be found in all application areas, from single axle city trailers all the way to hydraulically steered transport platforms of up to 250 tonnes.

Edbro

Edbro CS 17/18 Ultra: the lightest front lifting cylinders

Edbro, a manufacturer of hydraulic lifting cylinders and hydraulic components for dump trucks, will be represented for the first time at the JOST Group stand at the IAA. Edbro has been part of JOST Group since November 2012. At the IAA Commercial Vehicles, Edbro will present its further-developed hydraulic front lifting cylinders for dump trucks and tankers from the CS series. The topic of payloads is a particularly sensitive one when it comes to bulk material transport. For this reason, Edbro focussed specifically on the reduction of intrinsic weight in its further development of the CS series. Thus, Edbro will present the new, even lighter CS 17/18 Ultra front mount cylinders for the first time at the IAA in Hannover. By using high-quality materials and state-of-the-art production technologies, Edbro engineers have succeeded in reducing the weight of the outer cylinder by 29 kilograms and the eye ended cylinder by up to 21 kilograms. Thus the new CS 17/18 Ultra are up to 100 kilograms lighter than comparable cylinders. Newly developed, low-friction bearings provide smooth lowering of the CS 17/18 Ultra possible, which in turn provides greater comfort and safety.

Thanks to the one-piece cylinder construction and increased stop contact faces, the Edbro CS series has succeeded in ensuring a very high tipping speed without sacrificing reliability, safety or fuel consumption – even after many years of service. The use of highest-quality materials and special production expertise, such as laser welding technology for the cylinders, also allows extremely high lifting forces with maximum load safety.

About the JOST Group

The JOST Group is the worldwide leading producer of vehicle connection components for systems, modules and components for truck & trailer. Under the umbrella brand name of JOST, the comprehensive range of products is broken down into four areas: The JOST brand includes fifth wheel couplings, telescopic landing gears and accessories for semi-trailers, ball bearing turntables, king pins and container locks and components for alternating systems. Under the traditional brand name of ROCKINGER, the company produces towing hitches, drawbar eyes and towing drawbars for both transporters and trucks, as well as for use in the agricultural industry. TRIDEC is the leading provider of axle steering systems and single wheel suspensions for trailers. Edbro is the leading company in the field of vehicle-mounted hydraulic systems. Its range includes front and underfloor dump trucks and trailers and extension cylinders, as well as customer-specific hydraulic construction kits.

The JOST Group provides its products and services all around the world. The company is located on all continents, with distribution, production and development. With sales and production facilities in 18 countries, the company is the global partner of choice for the commercial vehicle industry. The JOST Group employs over 2,500 staff worldwide.