JSW Steel Ltd. has announced the opening of its cold roll mill 2 (CRM-2) facility at Vijayanagar Works in Karnataka.

JSW Steel Ltd. has announced the opening of its cold roll mill 2 (CRM-2) facility at Vijayanagar Works in Karnataka.

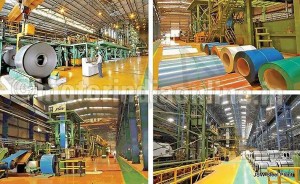

The new CRM-2 complex, with a production capacity of 2.3 million tonnes per annum (MTPA), is the most sophisticated plant by configuration with capability to produce high-strength and advanced high-strength steel, both in uncoated and coated (galvanized and galvannealed GI and GA) categories and wider width upto 1870mm. The facility includes a continuous annealing line, which is the first to start operations in India.

JFE Steel, which has a 15 per cent stake in JSW Steel, has been providing technical assistance to develop various grades of auto steel, including steel for external panels for automobiles, to meet the high domestic and international demand.

Dr. Vinod Nowal, Deputy Managing Director, JSW Steel, said: “The CRM-2 is equipped with the latest technology to produce continuously annealed CR upto a strength level of 980 MPA (UTS) and auto galvanizing line with capability to produce both GI & GA upto a strength level of 590 MPA (UTS). At present, the high strength and higher grades are mostly imported.”

JSW Steel has commissioned the phase-1 of CRM-2 consisting of 2.3 MTPA pickling line coupled with tandem cold mill (PLTCM), 0.95 MTPA continuous annealing line (CAL-1) and 0.4 MTPA continuous galvanising line (CGL).

Phase-2 of the plant consisting of 0.95 MTPA CAL-2 is scheduled to be commissioned in the first half of FY16. The new plant will be the cornerstone of JSW Steel’s growth story enhancing the share of value-added items in the product basket of the company.

With India on the road to becoming a global hub for automobiles, demand for high-end steel by the auto sector is likely to see an exponential growth.