New MD leads company progress

The year 2015 has been quite eventful for Knorr Bremse India Commercial Vehicle Systems (KBI CVS). It picked up steam at the right time, both internally and externally. While a major internal change was the appointment of Mr. S. Krishan Yogi as Managing Director, accompanied by a lot of operational process changes, externally the company could leverage its supply and distribution network.

Meanwhile, the Anti-lock Braking System (ABS) for Indian commercial vehicles came into force in April 2015, and the subsequent, across platform, implementation happened in October 2015. Before the regulation KBI had penetrated the aftermarket with vigorous training at the workshop level.

“We were able to cater to the major part of the aftermarket ABS kits through our advance preparedness and a robust network of distributors and dealers. The entire process also involved working with Authorised Service Centres (ASCs) and mechanics where our service engineers were trained on ABS fitments and the use of ABS,” revealed Mr. Yogi, along with his colleague, Mr. Arun Bisht, Head – Sales, Marketing & Customer Applications.

“We were aware of the aftermarket consumption pattern and the teething issues since we started even before the OEMs demand came pouring. While this helped us have a smooth start-up with the OEMs, the demand for our products went up after ABS was made mandatory for CVs. We started working on the supplier network a year ahead, where the technology was involved in finalizing the design of the product and consolidate the earnings from our distribution centres in Europe and the Asia Pacific region,” explained Mr. Yogi.

KBI introduced ABS 8, the latest generation of ABS, the launch of which was well-timed with impending regulation, with a view of supporting the OEMs in the country to have an advanced version of ABS as in other developed parts of the world. The basic version of ABS8 comes with many features which were available only in the advanced ECU of ABS6, the earlier version.

The next generation modular ABS8 safeguards the customer by making the ABS release future proof along with a host of software features. This enhances the performance of the vehicle and replaces the hardware by including software features through ABS8 ECU.

Asked about the need to train and educate the ASC, Mr. Yogi was quick to add: “To successfully expand my brand, I have to educate and connect with my end user and see that whenever the truck is opened at a dealership or at a road side mechanic, they ask for Knorr Bremse product. We give priority to educating and training ASCs so that they can generate demand along with the end users preferring the brand. While there are infrastructure developments expected, new regulations like the Trailer Code, Truck & Bus body Code and Passive Safety will lead to a wider use of KBI CVS products.”

With a stable market and strong economy KBI’s growing presence as OE and the host of regulations will see demand for KBI CVS products go up. “This will give us an opportunity to expand our product basket as well as the market share,” beamed Mr. Yogi.

Attuned to adversity

According to Mr. Yogi, the end results cannot be achieved unless the internal mechanism gets smoothened. “We conduct open house with our shop floor employees every month to understand their problems and issues. The information flows from bottom to top and every action or discrepancy is thoroughly reviewed,” informed Mr. Yogi.

Streamlining the work flow and helping the workforce understand their roles and responsibility have enabled people to think like leaders. “A five-year plan is designed for the company and a yearly goal plan for all the line of employees. The clarity has already reaped rewards. In last 9 months we have had 100 per cent growth in our monthly sales,” said Mr. Yogi.

Further, Mr. Yogi relied on the Total Quality Management (TQM) for improving customer satisfaction, Total Productive Maintenance (TPM), Lean Manufacturing & Energy conservation concepts to have improvement in productivity for better business results. The OEM customers would continue their pressure on price reduction from their suppliers and we have a plan to mitigate this risk through cost reduction initiatives such as value engineering, and global sourcing. We will also have our full focus on the quality system at the plant, through total employee involvement, while fully utilising statistical tools for process optimization and control. We are also using the Total Cost Management (TCM) system to further improve on cost in all related areas. There is complete focus on safety management through integration with the overall Safety Health and Environment (SHE) management system.

Honing local capabilities

For Mr. Yogi, ‘Make in India’ doesn’t only mean manufacture in India. Through this initiative he also intends to push the industry size to a new level. “We also plan to bring new products to make India our export hub. It is the right time to go beyond the India volumes and showcase to the world what our local expertise can offer.”

KBI CVS has become the global hub for ASA’s along with viscous dampers which will be made in India. This will largely catapult the company from only a domestic supplier to an export-based supplier. “We have growth plans to increase the export content in our total sales. Total sales growth will be five times the industry growth,” indicated Mr. Yogi.

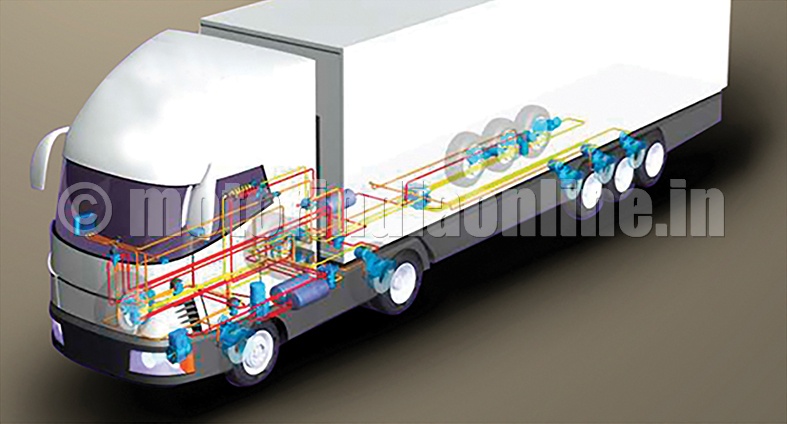

It is evident that through high value engineering and streamlining the process, KBI CVS wants the world to acknowledge its end-to-end solutions, from engine to the foundation brake, along with axillary braking and lift axle control systems.

Advanced technologies and R&D

The Knorr-Bremse Group is known as a global technology trend-setter, holding a number of patents and innovations towards vehicles safety and technology development.

Starting from the ABS innovation to the ESP developed over it, to the latest systems including Advance Emergency Braking System (AEBS), Adaptive Cruise Control & Braking (ACB), Lane Departure Warning Systems, Knorr-Bremse has been a pioneer in a wide range of technologies as well as in various advanced combination of technologies based on radar and camera.

Carrying the global innovation DNA, KBI CVS’ relentless quest for innovation has seen it register two digit patents, some of them not just for India but on a global scale, in a very short span of time. KBI had even pioneered the Hill Start Assist (HSA) technology in India which has made vehicle movement in hills a lot safer. The technology which is available in premium cars was made available for trucks in India at viable costs. “Engaging with the customer right at the design board level gives huge benefits, thus providing the optimized cost products,” said Mr. Yogi.

KBI CVS also has a full-fledged product testing and validation facility for in-house testing for product reliability. “Our manufacturing process ensures 100 per cent testing of all products on world class testing equipment with Poka Yoke’s to ensure error proofing during assembly and manufacture,” added Mr. Yogi.

KBI CVS was incorporated in February 2003. It started commercial operations in August 2005 at the new manufacturing facility at Hinjawadi, about 150 km south-east of Mumbai.

A multi-faceted personality, Mr. Yogi is capable of handling the KBI CVS operations in the country. He also finds time to engage in social activities, including supporting orphanages in locations such as Gurgaon, Delhi, Pune and Sonipat. He is also associated with several national-level organisations working for the welfare of women and children.

In recognition of his efforts, Mr. Yogi was honored with the ‘Sonipat Ratan’ Award in the Industry Category by the Chief Justice of India. Under his able leadership, KBI CVS is sure to attain greater heights in the coming years.