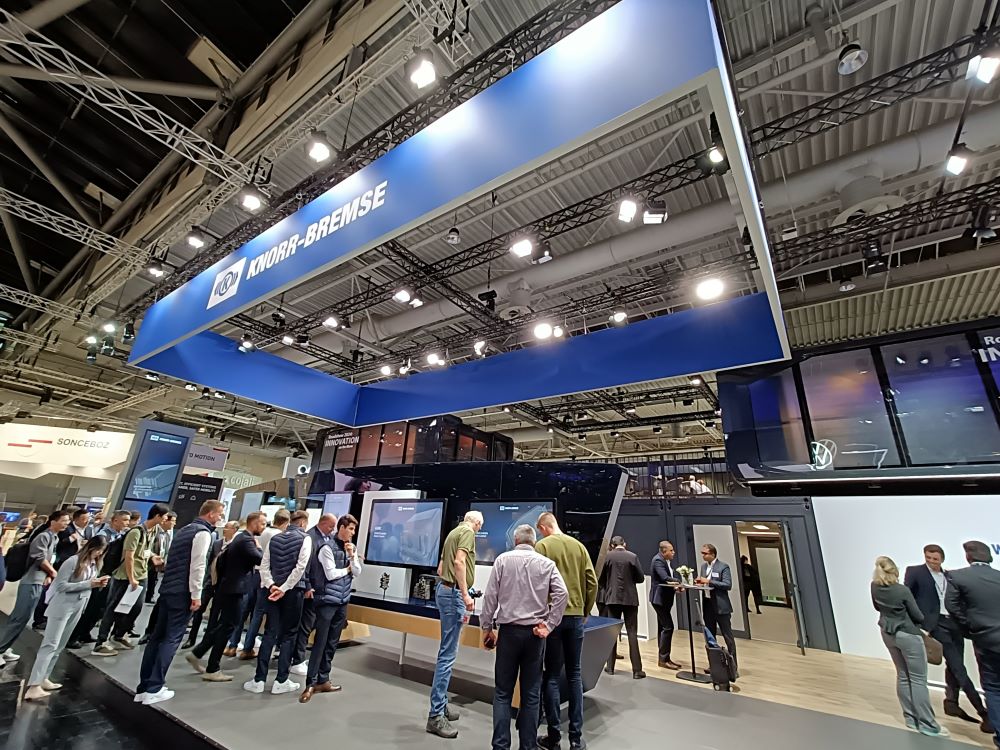

At IAA Transportation 2024 in Hanover, on September 17- 22, 2024, the Center Display of the Knorr-Bremse booth in Hall 12 (Booth C21) will showcase safety-critical solutions that respond to defining industry trends and the ongoing transformation of road traffic and transportation.

Bernd Spies, Member of the Executive Board of Knorr-Bremse AG with global responsibility for the Commercial Vehicle Systems division: “Knorr-Bremse has been a driving force behind the development of innovative mobility and transportation technologies for almost 120 years. Our safety-critical solutions for trucks, trailers and buses make a key contribution to improving safety on roads around the world. Indeed, road safety is part of Knorr-Bremse’s DNA, motivating us to develop new products or upgrade existing ones. At IAA Transportation, we’ll be presenting technologies that should play a vital role in bringing about an accident-free future for road traffic, as well as other solutions. I very much look forward to discussing them in person with industry colleagues in Hanover.”

Wheel end with modular SYNACT® disc brake family

Knorr-Bremse’s modular SYNACT® disc brake family is the latest outcome of decades of experience in the development of pneumatic disc brakes for commercial vehicles, of which the company has already manufactured over 50 million units. The new product line includes axial and radial brakes, and achieves a whole new level in terms of performance, weight and efficiency. SYNACT saves up to 48 kilograms of weight per vehicle and is one of the most energy-efficient air disc brakes ever designed. The Active Caliper Release (ACR) function also saves fuel and reduces each vehicle’s carbon footprint. Knorr-Bremse already plays a key role at the safety stage of the commercial vehicle approval process, and will expand this role to include emissions – specifically, brake-dust emissions – as EURO 7 is introduced.

Chassis control: GSBC and the electromechanical braking system

The latest, state-of-the-art generation of the Global Scalable Brake Control (GSBC)

– representing a global, modular approach to system design – has just enjoyed a successful market launch. The modular design reduces the many different components in conventional braking systems to a single, technical brake control platform, enabling manufacturers to simplify system layouts and save on parts, weight and installation costs. The system supports all key brake control functions such as ABS and ESP, interfaces with cutting-edge driver assistance systems, and helps manufacturers comply with the latest cybersecurity standards. With GSBC, electrically powered commercial vehicles in particular benefit from the integration of drive motors into the vehicle dynamics control loop, extending vehicle range and reducing brake pad wear. Manufacturers opting for GSBC will be able to upgrade it to a high- redundancy system (rGSBC) for highly automated driving (HAD) at cost-efficient prices.

As a leader in the development of technologies for safety-critical subsystems, Knorr-Bremse is playing a key role in the evolution of the Electromechanical Braking System (EMBS). The system can replace traditional safety architectures with a new technology offering full “brake- by-wire” capabilities. EMBS is a comprehensive braking solution that includes a redundant electrical power supply, redundant brake control unit and electromechanical brake actuators, as well as a built-in parking brake function. Knorr-Bremse’s new EMBS technology meets the same high standards of safety, reliability and durability as the company’s electropneumatic braking systems. But EMBS offers additional advantages in terms of installation space, noise generation and braking precision.

The Low-Noise Silencer is a silencer that cuts the noise emitted by the release of compressed air from vehicles to just 68 dB(A) – the current standard specifies 72 dB(A). This means that the Low-Noise Silencer is a perfect fit with the needs of electrified commercial vehicles operating in noise-sensitive areas such as city centers.

State-of-the-art steering portfolio

As one of the world’s leading manufacturers of steering systems for commercial vehicles, Knorr-Bremse will be presenting Electric Power Steering (EPS) and Advanced Hybrid Power Steering (AHPS) at IAA Transportation.

The all-electric EPS system supports two of the most important developments in the commercial vehicle industry: electrification and automated driving. Regardless of the underlying drive technology, EPS consistently applies the “power-on-demand” principle to reduce the vehicle’s energy and fuel consumption, which in turn cuts both energy costs and carbon emissions as a whole. Knorr-Bremse’s all-electric EPS also lays the foundations for steer-by-wire solutions – next-generation steering systems with no mechanical linkage between steering wheel and steering actuators.

By using torque overlay to enhance manual steering, the electrohydraulic AHPS system can amplify, attenuate or totally replace the driver’s steering input.

Perfect for implementing a wide variety of driver assistance functions, both systems support ADAS and HAD requirements and in terms of development, comply with all the latest standards such as ISO 26262.

Advanced driver assistance systems (ADAS) capable of monitoring blind spots

Knorr-Bremse’s next-generation Advanced Driver Assistance Systems (ADAS) underscore the company’s position as a reliable partner in the ongoing development of safety

technologies for commercial vehicles. Knorr-Bremse is a partner of choice for companies implementing EU General Safety Regulation II (GSR II), which came into force for first vehicle registrations on July 7, 2024. Solutions include, for example, collision warning systems such as the Blind Spot Information System (BSIS) and Moving Off Information System (MOIS), which alert drivers to possible collisions with approaching pedestrians or cyclists. Knorr-Bremse will also be presenting a new, pioneering driver assistance system in the form of the Fusion Front ADAS, which uses a combination of front-facing camera and radar to detect complex traffic conditions and relevant objects. Among the functions included in Knorr- Bremse Fusion Front ADAS are the Pedestrian Advanced Emergency Braking System (PAEBS) and Lane Keeping Assist (LKA). The system also takes care of statutory functions such as the Advanced Emergency Braking System and the Lane Departure Warning system.

New air supply and air treatment solutions

Knorr-Bremse is a leader in the development of e-vehicle compressors optimized for low- noise, high-efficiency air supply systems. The Rotary Vane Compressor features a new e- motor for electric commercial vehicles with low to medium air requirements. At IAA Transportation, Knorr-Bremse will be showcasing the exceptionally reliable and efficient Electric Screw Module (a screw-type compressor combined with an electric motor) – an ideal solution for vehicles with medium to high air requirements that also minimizes noise emissions and vibration levels. In addition, Knorr-Bremse is developing oil-free compressor technology that further improves energy efficiency and sustainability while simultaneously reducing maintenance overheads. The company will also present the iAPU (intelligent Air Processing Unit) which, in addition to saving fuel by intelligently managing various vehicle functions, also controls the electric motor in the rotary vane compressor.

The Global Scalable Air Treatment (GSAT) technology platform overcomes the worldwide challenges associated with electronic air processing by combining all functions for many different types of vehicles around the world in a single, modular, scalable and integrated solution that complies with the most important statutory and regulatory standards. And for manufacturers looking to create even more cost-efficient, space-saving vehicle architectures, GSAT can also accommodate an electronic parking brake.

EV drivetrain with Brake Resistor System (BRS)

In any electrified commercial vehicle, the liquid-cooled, high-performance Brake Resistor System (eBRS) provides a zero-emission, sustained-action braking function at all times, regardless of the vehicle battery’s size or charge level. The Brake Resistor’s scalable, modular design is configured for seamless integration into a vehicle’s drive, thermal and energy management systems. And by optimizing BRS integration with these systems, manufacturers can take advantage of additional benefits and functionality.

Other innovations include the Electromechanical Clutch Actuator (ECA), which enables high-precision control of clutch positioning without the need for pneumatics. The fully integrated electropneumatic Automated Manual Transmission (AMT) systems and pneumatic Concentric Clutch Actuator (CCA) reflect Knorr-Bremse’s multidisciplinary expertise in the development of pneumatic, electropneumatic and electronic systems. All systems meet the most demanding service life requirements while combining optimized shifting performance with reduced fuel consumption.

Knorr-Bremse’s damper expertise is reflected by dampers for controlling noise and vibrations, capable of counteracting NVH (noise, vibration and harshness) and transmission wear even in high-speed electric drivetrains. The company will also present the latest generation of viscous dampers (V-DEX+) which feature improved damping performance and a longer service life despite their reduced weight.

Trailers with innovative wheel end, driver assistance and chassis control products

Currently the market’s lightest 22.5-inch disc brake for trailers, the field-proven NexTT® is a single-piston design that boasts impressive energy efficiency. Equipped with optional ACR, the disc brake helps vehicle operators to minimize costs and save fuel. In addition, Knorr- Bremse will showcase driver assistance solutions for trailers such as iReverse (dock approach assist) and TPMS (tire pressure monitoring system), both designed to make commercial driving operations even safer.

In the field of chassis control, Knorr-Bremse will be presenting the latest generation of the iTEBS® X intelligent electronic trailer braking system. The system is a new global platform that combines an electronic control unit, sensor technology, a pneumatic brake control system and braking functions such as ABS and load-dependent braking in a single, compact assembly. To accompany and enhance iTEBS X, Knorr-Bremse will be presenting a new, cloud-based configuration platform, Online Configuration Tool (OCT), as a futureproof diagnostics concept. The digital solution includes a Software Update Management System (SUMS) that complies with the latest regulatory requirements set out in UNECE R156.

Knorr-Bremse is also presenting the latest generation of the POM Alcon+ parking and maneuvering valve with integral lift/lower actuation. Together with the recently introduced Chassis Suspension Module (CSM), the POM can also be used with conventional air suspension; it is already compatible with Knorr-Bremse’s proven iLvl system for electropneumatic air suspension. Among the other trailer solutions on show will be iTEMP, a supplementary modulator that links up to the trailer’s EBS. It features two 5 V CAN (Controller Area Network) connectors, and in addition to performing core ABS control functions, acts as an interface with the trailer information module or a telematics system.

Meet up with Knorr-Bremse: Hall 12, Booth C21

Knorr-Bremse will showcase the company’s range of innovative products and services for overcoming the mobility challenges of today and tomorrow at leading industry trade fair IAA Transportation in Hanover. Knorr-Bremse will share its latest developments with trade visitors in personal meetings and multimedia-based presentations, seeking to learn more about customers’ ideas and plans for the future. Knorr-Bremse looks forward to welcoming all visitors to IAA TRANSPORTATION in Hanover on September 17-22, 2024 (Hall 12, Booth C21).