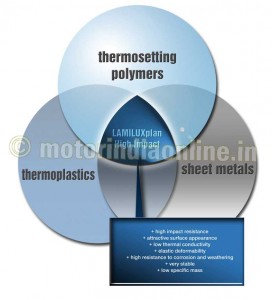

The automotive industry is increasingly backing sophisticated composites for construction of lightweight commercial vehicles. They  must be stable, light and very durable in order to meet the requirements of weight reduction and longevity while focusing on energy-efficient and sustainable mobility. With the new fiber reinforced composite LAMILUX High Impact, LAMILUX, the market leader in the production of GRPs in Europe, has developed a new facing material which combines all the positive features of thermoplastic and thermosetting materials and of sheet metals. It is primarily intended to be used as a surface for sandwich elements for side wall and roof structures.

must be stable, light and very durable in order to meet the requirements of weight reduction and longevity while focusing on energy-efficient and sustainable mobility. With the new fiber reinforced composite LAMILUX High Impact, LAMILUX, the market leader in the production of GRPs in Europe, has developed a new facing material which combines all the positive features of thermoplastic and thermosetting materials and of sheet metals. It is primarily intended to be used as a surface for sandwich elements for side wall and roof structures.

With the fiber-reinforced composite LAMILUX High Impact, it has been possible to combine the most compelling product advantages of three major construction materials in commercial vehicle design. It has the impact resistance and surface appearance of polished metal facings, such as aluminum, for example, while at the same time possessing the low thermal conductivity and elastic deformability of thermoplastic materials and having high resistance to UV, weathering and corrosion and the rigidity, stability and low specific mass per unit area of thermosetting polymers.

LAMILUX High Impact, at the same time, compensates for the disadvantages of materials, such as susceptibility of metals to corrosion and the poor paintability of thermoplastics.

LAMILUX High Impact, at the same time, compensates for the disadvantages of materials, such as susceptibility of metals to corrosion and the poor paintability of thermoplastics.

As Stefan Bachstein, Technical Director for LAMILUX, explains: “Due to its extreme impact resistance and tensile strength, our new material withstands the effects of even the strongest frontal forces.”

According to him, this has been proved in numerous standardized test series. Examples include the Charpy impact test according to ISO 179/2n as well as the tests for flexural strength according to DIN EN ISO 14125/WKII and tensile strength according to DIN EN ISO 527-4/2/2.

According to these tests, LAMILUX High Impact achieves an impact resistance of up to 100 kJ/m² and a flexural strength of 305 N/mm². The value for the tensile strength has been determined as being 240 N/mm². By way of illustration, a 1.0 cm wide strip of LAMILUX High Impact with a thickness of 0.8 mm only tears with a tensile loading upwards of 155 kg.

Stable, durable material

“We have developed this durable material with a high-quality, brilliant outer surface specifically for  use as a facing for sandwich panels in vehicle construction,” explains Technical Director Stefan Bachstein. He goes on to say that the processing industry will profit in particular from the advantages which LAMILUX High Impact will bring as a thermosetting polymer material.

use as a facing for sandwich panels in vehicle construction,” explains Technical Director Stefan Bachstein. He goes on to say that the processing industry will profit in particular from the advantages which LAMILUX High Impact will bring as a thermosetting polymer material.

“We can produce the material in all RAL and NCS shades and in colors customized according to client requirements. This means that a subsequent lacquer finish is not necessary, although it would be possible without any problems and without any complex surface treatment”, he adds.

“We can produce the material in all RAL and NCS shades and in colors customized according to client requirements. This means that a subsequent lacquer finish is not necessary, although it would be possible without any problems and without any complex surface treatment”, he adds.

Further, he avers that the material further offers a high level of convenience in processing, as it is easy to bond and can be manufactured in widths of up to 3.20 metres.