Compressed natural gas (CNG) is an alternative fuel to super unleaded or unleaded gasoline and diesel, particularly as it is cheaper and  more environmentally friendly. Natural gas engines emit around 25 per cent less CO2 than gasoline engines and some 15 per cent less than their diesel counterparts. What’s more, emissions of particularly harmful nitrogen oxides are reduced by 53 per cent and 95 per cent, respectively. The CO2 balance improves even more when biogas from renewable sources is added to the natural gas.

more environmentally friendly. Natural gas engines emit around 25 per cent less CO2 than gasoline engines and some 15 per cent less than their diesel counterparts. What’s more, emissions of particularly harmful nitrogen oxides are reduced by 53 per cent and 95 per cent, respectively. The CO2 balance improves even more when biogas from renewable sources is added to the natural gas.

On account of the high energy content and low price, a vehicle run on natural gas can cover a far greater distance for the same cost – roughly twice as far as when using super unleaded gasoline. And although it is often confused with liquefied petroleum gas (LPG), compressed natural gas has clear advantages thanks to its significantly higher energy content.

Natural gas-powered vehicles are therefore one of the things the automotive industry is focusing on its sustainable mobility concepts. Another factor is official targets such as those of the European Union, which has ruled that the average amount of the greenhouse gas CO2 emitted by manufacturers’ vehicle fleets must be reduced by 40 per cent as in 2008 to 95 g/km by 2020.

High-pressure tanks for natural gas-powered vehicles are frequently made of steel or aluminium (Fig. 1). Thin-walled steel and aluminium inliners that are wrapped and rein-forced with a composite material are much lighter and have also been tested in volume production. The composite consists of continuous carbon and/or continuous glass fibers soaked using a thermoset reaction system (e.g., epoxy resin) that is cured thermally after wrapping the inliner.

High-pressure tanks for natural gas-powered vehicles are frequently made of steel or aluminium (Fig. 1). Thin-walled steel and aluminium inliners that are wrapped and rein-forced with a composite material are much lighter and have also been tested in volume production. The composite consists of continuous carbon and/or continuous glass fibers soaked using a thermoset reaction system (e.g., epoxy resin) that is cured thermally after wrapping the inliner.

Polyamide 6 instead of steel or aluminium

A new lightweight construction concept for natural gas tanks uses thermoplastic, blow-molded inliners that are also wrapped with a continuous carbon/continuous glass fiber-reinforced thermoset composite. These systems weigh four times less than a tank made entirely of steel, which reduces the weight per vehicle by three to four percent, thus cutting their CO2 emissions significantly.

Only a small number of thermoplastics are suitable for manufacturing the inliners. The plastics need to exhibit excellent barrier  properties relative to natural gas, which consists mainly of methane. Non-polar thermoplastics, such as polyolefins, are therefore less suitable or require elaborate measures to minimize their gas permeability. Plastics also have to be extremely resilient in cold conditions and highly flexible, as it must be possible to operate and fill CNG tanks even at -40°C.

properties relative to natural gas, which consists mainly of methane. Non-polar thermoplastics, such as polyolefins, are therefore less suitable or require elaborate measures to minimize their gas permeability. Plastics also have to be extremely resilient in cold conditions and highly flexible, as it must be possible to operate and fill CNG tanks even at -40°C.

At these temperatures, thermoplastic inliners “shrink” to a greater extent than the composite shells surrounding them. The entire system expands instantaneously during filling as a result of the gas pressure. The inliners must not tear or crack despite the cold conditions.

Excellent permeation properties

LANXESS studied various grades of Durethan in preliminary testing to see whether non-reinforced polyamide 6 meets the strict permeation requirements for thermoplastics for CNG tanks. The results were very positive. As well as good barrier behavior, the polyamide 6 materials also need to offer excellent low temperature properties and good blow molding characteristics. This is a complex task in material development, as the barrier properties and impact-strength modification in particular have a negative impact on each other.

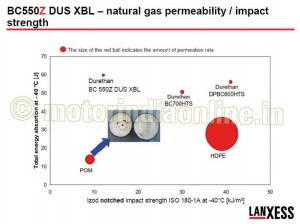

LANXESS has nevertheless recently succeeded in manufacturing low-temperature modified polyamide 6 grades for blow molding that also retain their excellent barrier effect against natural gas. Compared to high density polyethylene (HDPE), these materials – as LANXESS was able to ascertain using 200 micrometre thick films – are 100 times less gas-permeable (Fig. 2). The barrier behavior is around 10 times better than for polyoxymethylene (POM). As shown in natural gas permeation testing on three millimetre thick test plates made of the polyamides, no measurable gas losses occur even after six months.

LANXESS used these results to design a new polyamide 6 specifically for CNG pressure tanks. Using the material as a basis, Kassel-based xperion Energy & En-vironment GmbH – an Avanco Group company that has made a name for itself in developing and manufacturing lightweight composite components for the energy and environmental sectors – worked in close cooperation with LANXESS to develop a CNG tank all the way to series production (Fig. 3). Special challenges that xperion overcame during this process included producing an appropriate design for the pressure tank and valve and adapting the composite wrapping technology to the polyamide inliner.

Economical processing

The new polyamide 6 shows similar and in some instances better toughness at low temperatures and enhanced barrier behavior in resisting natural gas than the materials used in preliminary testing. It can be processed economically using conventional extrusion blow molding and can also be used to manufacture large CNG pressure tanks, thanks to its excellent melt stiffness. Manufacturing is more cost-effective, as the material is much more heat-stable than HDPE, for instance.

The thermoset composite wrapping that reinforces the CNG tanks can therefore be cured faster at higher temperatures. The material is also much more dimensionally stable than HDPE, for example.

This technology does not require the costly forming and welding operations needed for manufacturing sheet steel pressure tanks, which cuts production costs significantly. Manufacturing tanks with the new polyamide 6 is also more cost-effective than the production of aluminium tanks. Blow molding of the polyamide 6 is much more energy- and cost-efficient. It also enables cost-effective integration of functions such as the valve port.

This technology does not require the costly forming and welding operations needed for manufacturing sheet steel pressure tanks, which cuts production costs significantly. Manufacturing tanks with the new polyamide 6 is also more cost-effective than the production of aluminium tanks. Blow molding of the polyamide 6 is much more energy- and cost-efficient. It also enables cost-effective integration of functions such as the valve port.

xperion tested the jointly developed composite-reinforced CNG tank in extensive field testing in summer 2011, assessing its suitability for everyday use. Prior to this, the tank passed the tests under the European Economic Commission for Europe (ECE) R110 vehicle standard for drive systems with compressed natural gas. Testing included drop tests from a height of 1.8 metres, burst pressure tests at over 550 bar, pressure pulsation tests with over 50,000 load cycles and pressure refueling at -40°C.

Outlook

Good growth could be in store for CNG pressure tanks based on polyamide 6, as compressed natural gas is becoming increasingly popular with consumers as a fuel, particularly because it is cheaper and more environmentally friendly. For example, around 19 per cent more natural gas-fuelled vehicles were registered in Germany in 2011 than in 2010. Their growth rate was therefore almost twice as high as that for the entire market.

HiAnt – tailored customer service

LANXESS helps project partners at all levels in developing thermoplastic components, from selecting the material, drawing up a component concept and CAE simulation to component testing and processing. This support is part of the HiAnt brand, which pools thermoplastic know-how to deliver a customized service (Fig. 4).

As well as material development, the services made available to xperion in the joint project included design advice, extremely complex simulation of load scenarios and various tests relating to natural gas permeation and the chemical resistance of the polyamides to media typically found in motor vehicles.