Madhus, a leading supplier of garage equipment in India, and the US-based Hunter Engineering Company, a leader in alignment systems, wheel and tyre service, brake service and inspection lane equipment, partnered in 2000 for servicing the Indian market. The two majors have continuously driven technology growth in the country’s garage equipment sector ever since.

Hunter, the market leader in the US with an 85 per cent share, is known for its expertise in technology, and its equipment are approved and used by vehicle manufacturers, truck and tyre dealers, as well as service facilities around the world. Having brought world-class technology to a highly cost-competitive Indian market, Madhus has now a lot more to offer to its customers as Hunter recently launched its latest products, namely, HawkEye Elite aligner and Road Force Touch balancer, in the Indian market.

Mr. B.M. Ravi, Managing Director, Madhus Garage Equipments Pvt. Ltd., said: “The idea of introducing new technology in the Indian market is to increase productivity and make it more convenient to service vehicles. It also increases profit, reduces stress and fatigue of the mechanics and helps raise customer satisfaction levels.”

The two new equipment were demonstrated by an expert from Hunter, Mr. Byron Morgan, International Training Manager, Hunter Engineering Company. Says Mr. Morgan: “The Hunter Hawk-Eye Elite has revolutionized the measurement of wheel alignment in vehicles. We took six years to develop the product and are now confident that the Hunter Hawk-Eye Elite (hardware) and the WinAlign (software) form a winning combination while the Road Force Touch is set to take wheel balancing to new levels.”

HawkEye Elite

Hunter’s HawkEye Elite offers its customers unprecedented productivity and other profitable advantages. New and patented QuickGrip adaptors and three-dimensional targets accelerate service with set-up times in seconds instead of minutes. Spring-loaded clamping arms adjust easily to various wheel sizes, and a simple thumb lever locks the clamp in place. Technicians can quickly attach the adaptors without concern for a perfectly centered target. Off-centered positioning has no effect on measurement accuracy.

The system’s patented clamping arms grip the tyre tread instead of the rim edge, removing the worry of damaging expensive rims from metal-to-metal contact. Only a protective rubber ring at the base of the adaptor contacts the rim. The entire adaptor and target assembly weighs only six lb, making it easy to handle and install. A special shop-tough polymer construction makes the assembly tolerant of accidental drops. The target itself contains no electronics and requires very little maintenance. Additionally, the assembly’s ultra-compact profile easily fits between narrow lift posts and other tight constraints.

New and patented HawkEye Elite digital imaging sensors include four high-resolution cameras that instantly update adjustment readings on-screen. Working with the newly designed targets, HawkEye Elite sensors provide 3D modelling of wheel position and orientation for the most accurate alignment measurements. Roll-forward compensation, exclusive to Hunter, allows a technician to compensate all four wheels and capture initial measurements in one quick motion. When equipped with the timesaving capabilities of a fully integrated alignment (FIA) lift, the system produces vehicle measurements for the customer in just 90 seconds.

New HawkEye Elite consoles include powerful Intel processors, running Hunter’s latest patented version of WinAlign alignment software on a Windows 7 operating system. HawkEye Elite systems include Hunter’s patented and award-winning CodeLink electronic steering system reset device and a VIN bar code scanner as standard features.

The software supports the use of a drive-on camera to assist with positioning the vehicle on the lift and the TouchRemote feature, which lets a technician operate the system remotely using an Apple iPhone, iPod touch or iPad device. The new console design also includes integrated storage and charging for popular accessories and a new touch-screen monitor option.

Road Force Touch

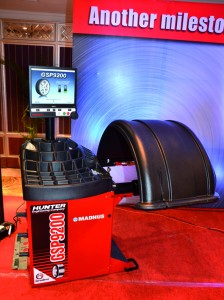

Built on Hunter’s GSP9700 legacy, the Road Force Touch produces exceptional balancing results and performs a Road Force diagnostic test faster than a traditional wheel balancer performs a typical balance.

During the balancing process, the Road Force Touch automatically applies Hunter’s patented load roller against the wheel and tyre assembly to simulate how a wheel performs under the weight of a vehicle to find hidden causes of vibration and vehicle pull. The automated Road Force test enhances the quality of service and opens the door to more revenue-generating opportunities without adding valuable service time.

The Road Force Touch also features a new intuitive touchscreen interface that simplifies operation and shortens the learning curve for new technicians. Technicians can activate any balancing function from one screen by touching the appropriate button or icon, saving time over scrolling through a grid of menu buttons. Live 3D graphics and animations display real-time wheel conditions and illustrate easy-to-understand instructions to resolve vibration and pull problems.

New software tools include eCal auto-calibration, on-demand videos and a powerful enhancement to StraightTrak lateral force measurement:

• Patent-pending eCal electronically and automatically calibrates the balancer without any input from the operator, making the Road Force Touch the only true “self-calibrating” balancer.

• On-demand videos provide convenient training on a variety of balancing and tyre changing topics to enhance operator skills.

• Patented StraightTrak, which measures pull forces in tyres and recommends wheel placement to cancel vehicle drift, now measures pulls on individual tyres.

The other improvements include a stronger, wear-resistant balancer shaft for long-lasting service, an Auto-Up Hood that saves time by automatically lifting the hood for the operator, and a standard 10-piece mounting collet set with storage to optimize wheel centering.